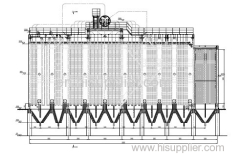

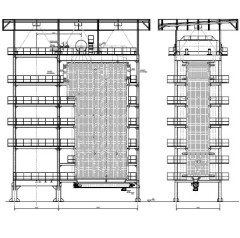

sinter cooler waste heat boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Model No.: | Waste Heat Boiler Q series |

|---|---|

| Means of Transport: | Ocean |

| Fuel: | waste heat |

| usage: | steel industry |

| output: | steam |

| sturcture: | water tube |

| pressure: | low or medium pressure |

| Style: | Vertical |

| Type: | Natural/Forced Circulation |

| Production Capacity: | 100 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | 3 months |

Product Description

In the process of steel production,the energy consumption of sintering processes accounts for about 10% of total energy consumption,second only to iron-making processes,list in the secong place.Total energy consumption in the sintering process,nearly 50% of the thermal was emitted into the atmosphere at the sensible heat formof sintering flue gas and a cooler.The waste heat recovery of sinter cooler,is the latest set of power generation technology that through recycling flue gas heat of drop-tail ore wind box of sintering maching and sealed section of sintering cooler and waste heat boiler recover heat energy,combining with power generation technology of low temperature waste heat,using over hot steam of waste heat boiler to promote Turbogenerator with low parameters to work.

The vertical water heat boiler developed by our company that applied to flue gas heat of sintering cooler of iron and steel industry,successfully solved the fouling,wear,leakage problem of waste heat boiler,at the same time this type of waste heat boiler is with a certain degree of adaptability for the flue gas temperature,flue gas dust.The use of this type of waste heat boilers,can reduce energy consumption of sintering processes,promote resource conservation and reduce the unit price of products to enable the enterprise to more competitive advantage.

The main specifications are as following:rated steam output5-130t/h rated steam pressure0.5-5.29MPA.

The vertical waste heat boiler developed by our company that applied to flue gas heat of sintering cooler of iron and steel industry,successfully solved the fouling,wear,leakage problem of waste heat boiler,at the same time this type of waste heat boiler is with a certain dagree of adaptability for the flue gas temperature,flue gas dust.

The vertical water heat boiler developed by our company that applied to flue gas heat of sintering cooler of iron and steel industry,successfully solved the fouling,wear,leakage problem of waste heat boiler,at the same time this type of waste heat boiler is with a certain degree of adaptability for the flue gas temperature,flue gas dust.The use of this type of waste heat boilers,can reduce energy consumption of sintering processes,promote resource conservation and reduce the unit price of products to enable the enterprise to more competitive advantage.

The main specifications are as following:rated steam output5-130t/h rated steam pressure0.5-5.29MPA.

The vertical waste heat boiler developed by our company that applied to flue gas heat of sintering cooler of iron and steel industry,successfully solved the fouling,wear,leakage problem of waste heat boiler,at the same time this type of waste heat boiler is with a certain dagree of adaptability for the flue gas temperature,flue gas dust.