Cement Kiln Waste Heat Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Model No.: | Waste Heat Boiler Q series |

|---|---|

| Means of Transport: | Ocean |

| Fuel: | Waste Heat |

| Output: | Steam |

| Usage: | Industrial |

| Structure: | Water Tube |

| Pressure: | Low Pressure |

| Production Capacity: | 100 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | 120 days |

Product Description

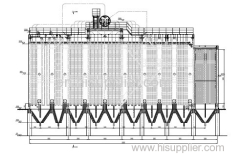

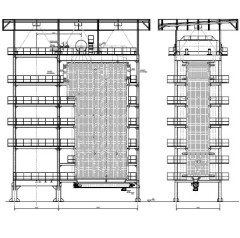

Cement Kiln Waste Heat Boiler is an efficient and reliable energy-saving product,which is mainly applied to cement making industry.According to different types and specification of lime kiln,technological process and production equuipment,our company has successfully developed high temperature,moderate temperature,low temperature and pure low-temperature waste heat boilers,which can be applied to cement industries with daily production capacity of 100t/d-10000t/d.Waste heat boiler has various form of structure,such as vertical type,horizontal type,vertical and horizontal combinatory,forced circulation and natural circulation.

For the specificity and diversity of lime kiln waste,our company has gathered rich experience in design and manufacture of Cement Kiln Waste Heat Boiler ,and has specific characteristics in reduction of air leakage,anti-abrasion and anti-soot-deposition.

This low temperature cement kiln waste heat boiler is a high efficiency boiler that produces slightly superheated steam mainly by using pre-heater kiln head chamotte cooling machine and kiln end pre-heater to dischareg 250~400 low-temperature waste heat flue gas and meanwhile generates electric power by using sligh superheated steam to push low thermal parameter turbine driving. The overall structue of cement kiln waste heat boiler employs vertical arrangement which has obvious features of flexible arrangement, small occupation, less investment in basic construction, small amount of air leakage and low rate of consumption for steel materials and so on. cement kiln waste heat boiler is very popular among users. This low-temperature gas waste heat used to generate electric power is an effective way to save energy and reduce consumption, and realize the comprehensive uses of resources, not only reducing the producing the prodcution costs of cement, but also raising the conomic effectiveness fo the enterprise and overcome electricity shortage. Meanwhile, cement kiln waste heat boiler also can lower the smoke evacuation temperature and soot exhausting concentration and diminish the emission of CO2, greatly reducing air pollution and greenhouse effect and realizing resources recylingin cement kiln waste heat boiler industry and clean production.

The main specifications are as following:rated steam output 4-55t/h rated steam pressure 0.5-3.82MPa

For the specificity and diversity of lime kiln waste,our company has gathered rich experience in design and manufacture of Cement Kiln Waste Heat Boiler ,and has specific characteristics in reduction of air leakage,anti-abrasion and anti-soot-deposition.

This low temperature cement kiln waste heat boiler is a high efficiency boiler that produces slightly superheated steam mainly by using pre-heater kiln head chamotte cooling machine and kiln end pre-heater to dischareg 250~400 low-temperature waste heat flue gas and meanwhile generates electric power by using sligh superheated steam to push low thermal parameter turbine driving. The overall structue of cement kiln waste heat boiler employs vertical arrangement which has obvious features of flexible arrangement, small occupation, less investment in basic construction, small amount of air leakage and low rate of consumption for steel materials and so on. cement kiln waste heat boiler is very popular among users. This low-temperature gas waste heat used to generate electric power is an effective way to save energy and reduce consumption, and realize the comprehensive uses of resources, not only reducing the producing the prodcution costs of cement, but also raising the conomic effectiveness fo the enterprise and overcome electricity shortage. Meanwhile, cement kiln waste heat boiler also can lower the smoke evacuation temperature and soot exhausting concentration and diminish the emission of CO2, greatly reducing air pollution and greenhouse effect and realizing resources recylingin cement kiln waste heat boiler industry and clean production.

The main specifications are as following:rated steam output 4-55t/h rated steam pressure 0.5-3.82MPa