Coking Waste Heat Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Model No.: | Waste Heat Boiler Q series |

|---|---|

| Means of Transport: | Ocean |

| Fuel: | Waste Heat |

| Output: | Steam |

| Usage: | industrial |

| Structure: | Water Tube |

| Pressure: | low or medium pressure |

| Production Capacity: | 100 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | 3 months |

Product Description

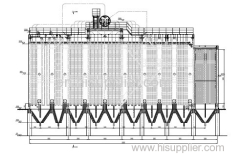

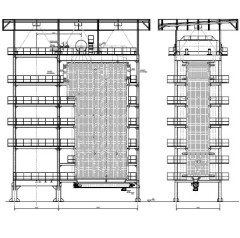

During the process of coking production,the coking plant willproduce a lot of waste gas with the temperature of 550-9500C.For further recycle of the waste gas,our company developed two typed of norizontal natural circulation water-tube type boiler of double (single)drum,namely,the boiler of supplemental combustion and the boiler without supplemental combustion.These two types of boiler are applicable to the coking industry.The layout of the boiler is classified into two types:the traditional,horizontal type and the new vertical type,among which the vertical layout of boiler has novel structure and advanced property.It is a new patent of waste heat boiler for the waste gas of coking exclusively developed by our company.The boiler with supplementalcombustion utilize the automatic coke oven gas burner.Firstly,the coke oven gas is burned insideor outside of the waste heat boiler,and then mixed with the waste gas of coking;it becomes the high temperature flue gas and enters into the boiler to be converted into rated steam.

The waste gas is exhaused through the boiler slag tube bank,super-heater,convection tube bank and steel pipe coal economizer;enters into the desulfurizing and de-dusting installation at the bottom;and then it is exhausted to the atmosphere by the induced draft fan through the chimney.The solidified slag bank is dispersed from the water-wall tube.The structure of the super-heater is the horizontal suspension structure,with high temperature area and low temperature area.The super-heater is cooled by surface tyoe of cooling or water.The convection bank adopts the in-line arrangement.In the middle of the convection bank,there is baffle wall through the multiple baffling;the convection bank.The coal economizer is the pipe coil bend economizer,adopts the transversal flow staggered layout.The unique membrane-type wall flue gas channel wall of the boiler can increase the heating surface,improve the seal and security of the boiler,as well as compact the structure of the boiler.

The new patent of waste heat boiler for the waste gas of coke has avoided the defects of the traditional horizontal waste heat boiler with one flue gas channel or multi flue gas channel.It can organically combine the various components of the boiler without the change of their fuctions,centralize the heating surface,simplify the structures,novel structure,low cost,smallfloor area,environment protection and energy conservation.

The main specifications are as following:rated steam output 5-75t/h,rated steam pressure1.0-9.8MPa.

The waste gas is exhaused through the boiler slag tube bank,super-heater,convection tube bank and steel pipe coal economizer;enters into the desulfurizing and de-dusting installation at the bottom;and then it is exhausted to the atmosphere by the induced draft fan through the chimney.The solidified slag bank is dispersed from the water-wall tube.The structure of the super-heater is the horizontal suspension structure,with high temperature area and low temperature area.The super-heater is cooled by surface tyoe of cooling or water.The convection bank adopts the in-line arrangement.In the middle of the convection bank,there is baffle wall through the multiple baffling;the convection bank.The coal economizer is the pipe coil bend economizer,adopts the transversal flow staggered layout.The unique membrane-type wall flue gas channel wall of the boiler can increase the heating surface,improve the seal and security of the boiler,as well as compact the structure of the boiler.

The new patent of waste heat boiler for the waste gas of coke has avoided the defects of the traditional horizontal waste heat boiler with one flue gas channel or multi flue gas channel.It can organically combine the various components of the boiler without the change of their fuctions,centralize the heating surface,simplify the structures,novel structure,low cost,smallfloor area,environment protection and energy conservation.

The main specifications are as following:rated steam output 5-75t/h,rated steam pressure1.0-9.8MPa.