80t/h Waste Heat Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Model No.: | QC Series |

|---|---|

| Means of Transport: | Ocean |

| Fuel: | waste heat |

| Output: | 80t/h |

| Usage: | industry |

| Structure: | water tube |

| Pressure: | 5.29MPa |

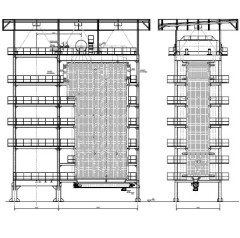

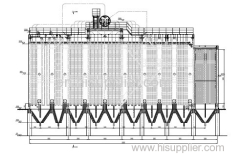

| Style: | a horizontal type with single drum |

| Type: | natural circulation |

| Production Capacity: | 50 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | six months |

Product Description

80t/h Waste Heat Boiler is designed for gas-making furnace waste recycling system, which is the use of integrated waste in the system burning waste heat boiler furnace dust fume produced a device to generate superheated steam. Features of 80t/h Waste Heat Boiler is:

Steam Quality

1.energy-saving to achieve thermal energy utilization. 80t/h Waste Heat Boiler is to use micro-dust concentration in flue gas remaining heat of waste recycling systems can be used for power generation, production, life of superheated steam.It does not use disposable fuel, so it has the characteristics of energy-saving and comprehensive utilization of energy.

2.furnace dust. it is conducive to environmental protection.

Due to the flue gas contains large amounts of coarse dust, the boiler uses combined inertia separation principle and gravitational separation principle to achieve separation of dust, reducing soot content.

3. low resistance, running economy.

80t/h Waste Heat Boiler heating surface by adjusting the flow rate of flue gas flow cross-sectional area to achieve the design, reducing the bulk resistance, conducive to the integration with other devices and reduce system power consumption.

4. compact.it looks neat in appearance.

Basic characteristics of 80t/h Waste Heat Boiler

1.boiler specification

index | parameter |

rated evaporation | 80t/h |

rated steam temperature | 485℃ |

rated steam pressure | 5.29MPa |

feed water temperature | 95℃ |

exhaust gastemperature | 150℃ |

boiler design efficiency | 82.1% |

import of boiler flue gas | 200000Nm3/h |

import of boiler flue gas temperature | 950℃ |

import of boiler flue gas dust content | 1825g/Nm3 |

2.boiler structure

80t/h Waste Heat Boiler is for gas furnace waste recycling systems.Boiler is tunnel layout according to the flue gas flow direction.Boiler main heating surface layout water screen,two superheater,convection tube bank,three economizer and two air preheater.Boiler adopts the type ofsingle drum horizontal natural circulation water tube.Flue dust is discharged from furnace through water screen,superheater,convection tube bank,economizer and two air preheater.

3.boiler pressure parts water volume table

parts | water volume m3 | remarks |

drum | 13.8 | the length of the straight section |

superheater | 5.8 | include the header and tube |

water pipe system | 35.2 | include the header and tube |

economic | 14.1 | include the header and tube |

total | 68.9 |

4.Schedule

Boiler Feed Water Quality

boiler type | boiler superheated steampressureMpa | hydrogen conductivity(25℃)/ μS/cm | hardness | dissolved oxygenb | iron | copper | sodium | Sio2 | ||||

μmol/L | μg/L | |||||||||||

standard values | Expectations | standard values | Expectations | standard values | Expectations | standard values | Expectations | |||||

drum boiler | 3.8-5.8 | - | - | ≤2.0 | ≤15 | ≤50 | ≤10 | - | - | - | ensure that the steam silicastandard | |

5.9-12.6 | ≤0.3 | - | - | ≤7 | ≤30 | ≤5 | - | - | - | |||

12.7-15.6 | ≤0.3 | - | - | ≤7 | ≤20 | ≤5 | - | - | - | |||

>15.6 | ≤0.15a | ≤0.1 | - | ≤7 | ≤15 | ≤3 | ≤2 | - | - | ≤20 | ≤10 | |

once-through boiler | 5.9-18.3 | ≤0.15 | ≤0.1 | - | ≤7 | ≤10 | ≤3 | ≤2 | ≤5 | ≤2 | ≤15 | ≤10 |

>18.3 | ≤0.15 | ≤0.1 | - | ≤7 | ≤5 | ≤2 | ≤1 | ≤3 | ≤2 | ≤10 | ≤5 | |

a no condensatedemineralization system in unit, hydrogen conductivity in the water supplyshould not exceed 0.30μS/cm. b When oxygenated, indicators in table 4 control ofdissolved oxygen. | ||||||||||||

Steam Quality

superheated steam pressure/Mpa | Na (μg/kg) | Hydrogen conductivity(25℃)/(μS/cm) | Sio2 (μg/kg) | iron (μg/kg) | copper (μg/kg) | |||||

standard values | expected value | standard values | expected value | standard values | expected value | standard values | expected value | standard values | expected value | |

3.8-5.8 | ≤15 | - | ≤0.30 | - | ≤20 | - | ≤20 | - | ≤5 | - |

5.9-15.6 | ≤5 | ≤2 | ≤0.15a | ≤0.10a | ≤20 | ≤10 | ≤15 | ≤10 | ≤3 | ≤2 |

15.7-18.3 | ≤5 | ≤2 | ≤0.15a | ≤0.10a | ≤20 | ≤10 | ≤10 | ≤5 | ≤3 | ≤2 |

>18.3 | ≤3 | ≤2 | ≤0.15 | ≤0.10 | ≤10 | ≤5 | ≤5 | ≤3 | ≤2 | ≤1 |

A No condensate demineralization system in unit,hydrogen conductivity of steam standard value is no greater than 0.30μS/cm,Expectationsis less than 0.15μS/cm. | ||||||||||