Float Glass Kiln Waste Heat Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| fuel: | waste heat |

| output: | steam |

| usage: | glass industry |

| sturcture: | water tube |

| pressure: | medium pressure |

| Style: | Vertical |

| Type: | Natural Circulation |

| Production Capacity: | 100 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | 3 months |

Product Description

Glass industry consumers huge energy every year.China has a top level of the float glass processing industry in the world,however here is still a big gap between the international level on energy consumption.the float glass kiln waste heat power generation system can further the utilization of the waste heat more than 70%,so the waste heat can be almost fully used.Superheated steam was generated by the high efficient vertical,water-tube,waster heat power station boiler and the temperature of the exhaust gas was lowered down to around 180.Then the superheated steam was used to generate clean, easy-to-use and convenient delivery power through tubine generator.By this method,not only the fuction of the waste heat was enlarged but also the lower temperature steam from lower pressure part of turbine generator can be used to heat heavy oil to meet the heat requirements of the workmanship of the glass industry.

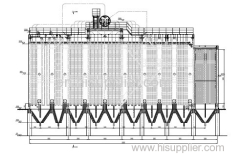

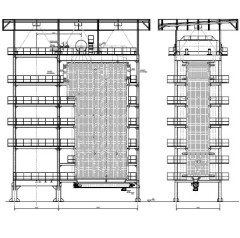

Float Glass Kiln Waste Heat Boiler

adopt single drum,widthwise layout,vertical,natural circulation,water tube type.The overall layout is "Ⅱ"type,wich overcomes the downsides of the traditional vertical,natural circulation waste heat boilers.They have the features of long service life,easy operation and maintain,safety,stable and cost saving.Float Glass Kiln Waste Heat Boiler

It can fully meet the requirements of the float glass furnance production lines,which fire heavy oil or nature gas.

The main specifications are as following:rated steam output3-35t/h,rated steam pressure 0.2-5.29MPa.