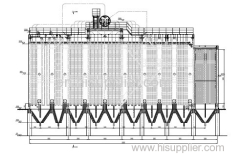

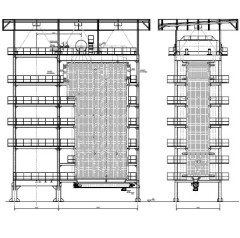

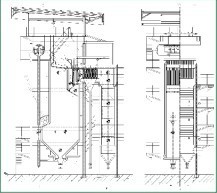

Calcium Carbide Furnace Waste Heat Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Model No.: | Waste Heat Boiler Series |

|---|---|

| Means of Transport: | Ocean |

| Fuel: | waste heat |

| Output: | steam |

| Usage: | industrial |

| Structure: | water tube |

| Pressure: | low or medium pressure |

| Style: | vertical or horizontal |

| Type: | natural circulation |

| Production Capacity: | 50 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | 5 months |

Product Description

Calcium Carbide Furnace Waste Heat Boiler is a device that relies mainly on the arc high temperature to melt lime and carbonaceous materials (coke,anthracite or petroleum coke),then react to generate calcium carbide.There is a great energy waste in the process of calcium carbide production,such as waste heat output from tail gas and sensible heat carried by calcium carbide tapping.The utilization of waste heat can bring considerable economic benefits for the enterprise,conform to national energy policy,achieve the purpose of environment protection and energy saving.

The characteristics of this series Calcium Carbide Furnace Waste Heat Boiler are as follows:

1.Gas exhaust temperature of the boiler is low,efficiency of waste heat utilization is high;

2. The equipment with compact conformation for each part and small floor area;

3.The waste heat boiler cleaning,blocking ash and other problems have been solved,output of boiler is stable;

4. Explosion-proof problem of waste heat boiler has been solved effevtively;operation of the boiler is safe and reliable;

5.The boiler employs special insulation structure with air tightness and simple structure;

6.With good dust cleaning ability of the boiler,flue gas dust concentration of the boiler is reduced effectively,which lay the foundation for the flue gas environmental protection.

7.The boiler meets the needs of different working conditions with good adaptability.

1.Gas exhaust temperature of the boiler is low,efficiency of waste heat utilization is high;

2. The equipment with compact conformation for each part and small floor area;

3.The waste heat boiler cleaning,blocking ash and other problems have been solved,output of boiler is stable;

4. Explosion-proof problem of waste heat boiler has been solved effevtively;operation of the boiler is safe and reliable;

5.The boiler employs special insulation structure with air tightness and simple structure;

6.With good dust cleaning ability of the boiler,flue gas dust concentration of the boiler is reduced effectively,which lay the foundation for the flue gas environmental protection.

7.The boiler meets the needs of different working conditions with good adaptability.

The main specifications are as follows:rated steam output of 2-35t/h,rated steam pressure of 0.5-5.29Mpa.