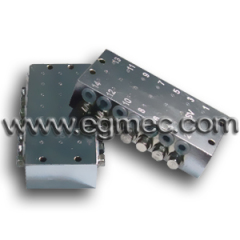

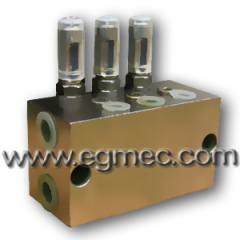

Dual Line Progressive Divider Valve

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2500 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | SGQ Series-221003 |

|---|---|

| Means of Transport: | Express, Ocean, Air, Land |

| Type: | Others |

| Certification: | Others |

| Brand Name: | EGMEC |

| Product: | Dual Line Progressive Divider Valve for centralized lubrication system |

| Ordering code: | SGQ-11 to 34 Series |

| Max. pressure: | 10MPa |

| Outlet ports: | 1-8 ports |

| Construction: | Single and double type |

| Medium: | Grease or indicated oil |

| Warranty: | One year quality guarantee |

| Quality control: | Standard tested before delivery |

| Replacement: | Lincoln lubrication divider parts |

| OEM and ODM: | Please contact us |

| Production Capacity: | 2500 |

| Packing: | Standard packing for exporting |

| Delivery Date: | Depending quantity |

Product Description

The SGQ dual line progressive divider valve is applied for the double nominal pressure 10MPa dry oil lubrication system, as a measure to the oil installations. It turns of the two oil supply for the pipeline under pressure from the oil pressure push the piston to the oil, complete quantitative distribution of grease lubrication points to each function.

There are single grease port and double grease port constructer of the SGQdual line progressive divider valve, the way out of the oil under the oil control only to the hole, when the piston by the oil discharge under positive and negative to the point for the delivery of oil slide grease; way out of the oil to the oil cooler there, down to the hole, the piston positive and negative drain down to the hole by the alternate for the delivery of grease to the lubrication points. Instructions to the oil cooler from the action bar directly observed the work to the oil cooler, you can also adjust the screw in easily adjusted within the provisions of the mouth of all the oil to fuel.

How to use the SGQ dual line progressive divider valve:

1. Environment must be specified using the specified media.

2. In the dusty, wet, harsh environment applications to use, should increase with the dust cover.

3. To the oil cooler of the two inlet and two, respectively, for the pipeline connection, and both sides are through, and a side of the inlet when not in use applications R3 / 8 plug closure.

4. A priority in the system oil cooler installed in parallel method for the pipeline and the distributor can join in on the left or right; followed by tandem installation method, the number of the most series do not allow more than three.

5. The priority given to the oil cooler oil cooler liner installed, and to the oil cooler lining contact surfaces should be smooth, not over tighten the mounting bolts, so as not to affect the normal work of deformation is too large.

6. The adjustment to the oil for the first spin out the stopper on the locking screw, and adjust the adjustment screw lubrication points according to the actual needs of the maximum and minimum range of adjustment to the amount of fuel to the fuel. Adjustment should be retracted in the direction to the state bar under the adjustment should tighten the screws after tightening.

7. The piston second side to the oil drain plug not allowed to demolish; plug leaks, tighten or replace the new seal.

8. If the machine lubrication points is odd, can be either a hole in the lower part of the separated components removed, and then plug the top of the plug hole in order to work.