Dual Line Modular Progressive Divider Valve

| Min. Order: | 5 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 3000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | SSPQ-P Series-221004 |

|---|---|

| Means of Transport: | Express, Ocean, Air, Land |

| Type: | Others |

| Certification: | Others |

| Brand Name: | EGMEC |

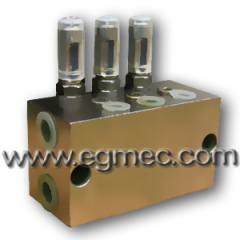

| Product: | Dual Line Progressive Divider Valve Modular Installation |

| Ordering code: | SSPQ-P series |

| Max. pressure: | 40Mpa |

| Outlet ports: | 1-8 ports |

| Construction: | Double type |

| Medium: | Grease or indicated oil |

| Warranty: | One year quality guarantee |

| Quality control: | Standard tested before delivery |

| Replacement: | Lincoln lubrication divider parts |

| OEM and ODM: | Please contact us |

| Production Capacity: | 3000 |

| Packing: | Standard packing for exporting |

| Delivery Date: | Depending quantity |

Product Description

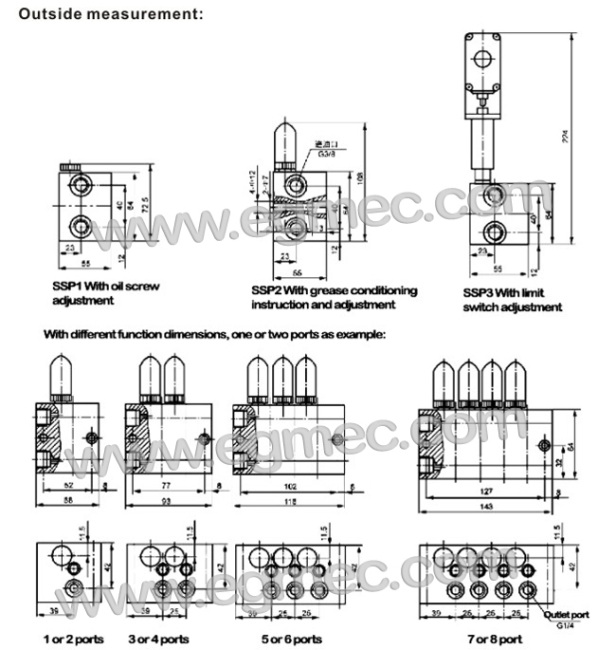

The series of SSPQ-P dual line modular progressive divider valve for nominal pressure 40MPa, grease or oil lubrication system in the two-wire, as a quantitative to the oil installations. By two alternating pressure for the pipeline to send grease to achieve quantitative delivery to all lubrication points for the two-lane distributor lubricants. Distributor has to bring the oil screw with movement direction adjustment device and device with three types of stroke adjustment.

1.With the oil screw of the distributor, the oil can not be adjusted, only choose a different index to the oil screw to change the oil to the oil.

2.With movement direction adjustment device distributor, feeding grease can be rated to the amount of oil in the range of zero to be adjusted, and the adjustment device through direct observation of movement is working to determine the distributor.

3.With a limit switch adjustment device of the distributor, feeding grease be rated to the amount of oil in the range of zero to be adjusted, and send signals through the limit switch to control the oil supply situation of lubrication points, each with only one distributor pieces of limit switch adjustment device.

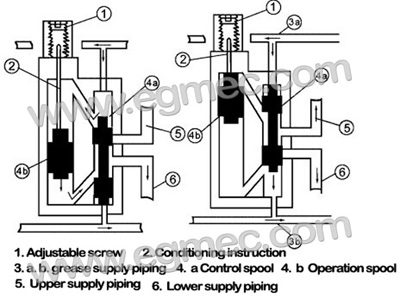

The principle of dual line modular progressive divider valve:

Dual line modular progressive divider valve each of the two connected through the piston lubrication points, respectively, a control hole in the piston and a working piston, the two inlet and two, respectively, for the pipe 3a, 3b connected, as an added pressure for the tubing, another is unloading.

As shown above, to the grease from the pump delivery, the dispenser control the oil supply line 3a enter the upper end of the piston, the control piston moves down first (this time the bottom of the control piston is squeeze the grease into the supply pipe 3b unloading ), so that work on the piston on the piston chamber and control chamber connected, and then working the piston moves down, this time by the working piston through the control of the extrusion of the grease piston ring groove is pushed to the lubricating oil outlet from 6 to point, completed the first cycle of the oil action. Switch to 3b for oil pipeline to begin the second cycle, the oil moves the piston in the same order distributor reverse the above actions, the oil port 5, the carriage of grease.

How to use theSSPQ-PDual line modular progressive divider valve:

1.In the dusty, wet, harsh environment applications should be used, with protective cover.

2.Divider valve in parallel priority in the system installation method, with the distributor for the pipeline connection on the left or right may be; followed by tandem installation method, to be on the side of the inlet pipe from the two closed G3 / 8 Remove plug up several in series does not allow more than two; if necessary, and serial combined installed.

3.To bring the oil screw the distributor (SSPQ1), to the oil can not be adjusted, only choose a different index to the oil screw to change the oil to the oil.

4.With movement direction adjustment device allocator (SSPQ2 type), and its adjustment to the oil, should be retracted in the direction to the state bar rotation limiter adjusting screw, according to the actual needs of lubrication points and minimum to maximum fuel range to be adjusted.

5.With a limit switch adjustment device allocator (SSPQ3), their adjustment to the oil, also in the direction of the state bar to be retracted, according to need adjustment.

6.To the port number into an odd number, the port will be between the corresponding screws removed, and to do that out of port with G1 / 4 plug closure, the upper and lower oil port connectivity, the piston moves forward and reverse all the oil from the oil statement. 7, for ease of removal from the splitter to the lubrication points, 90 ° bent pipe or use the best card sets joints.

8.With the distributor to install the surface should be smooth, not over tighten the mounting bolts to prevent deformation when used properly.

9.SSPQ1 and SSPQ2 type distributor suggested the use of GB70-85 mounting screws M6 × 50, SSPQ3 type distributor installed between the surface of the plate to be used with 30mm GB70-85 special mounting screws M6 × 85mm.

: