Modular Lube Progressive Divider Valve

50.0~65.0 USD

| Min. Order: | 20 Set/Sets |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | L/C, other, D/P, D/A, T/T, WU |

| Supply Ability: | 6000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | SSV16 Series -221028 |

|---|---|

| Means of Transport: | Express, Ocean, Air, Land |

| Type: | Others |

| Certification: | CE |

| Brand Name: | EGMEC |

| Product: | Progressive Divider Valve Manifold |

| Series number: | SSV16 Series |

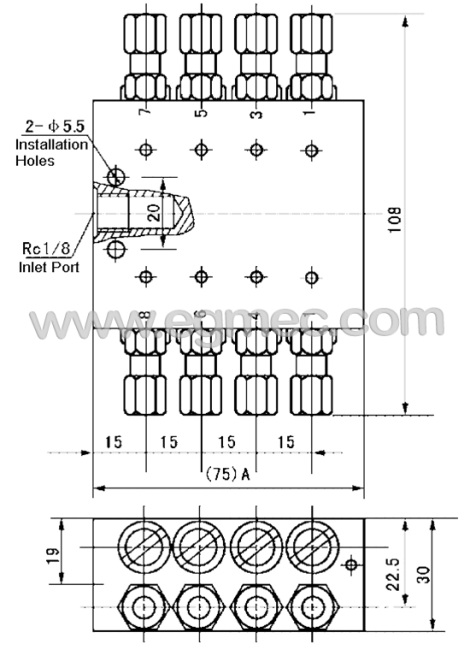

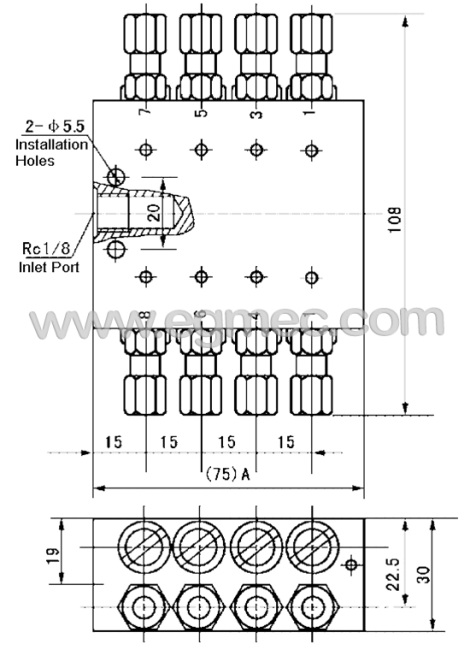

| Number of outlets: | 16 ports |

| Maximum operation pressure: | 300bar |

| Flow rate: | 1000mL/min. |

| Working temperature: | Around 25℃ |

| Feeding volume: | 0.2mL/cycle |

| Medium: | Cone penetration not less than 265 (25°C, 150g) 1/10mm grease |

| Superficial treatment: | Chrome plated as normal or black galvanization |

| Tested standard code: | JB/ZQ4550-97 national standard |

| Production Capacity: | 6000 |

| Packing: | Standard packing for exporting |

| Delivery Date: | Depending quantity |

Product Description

Brief introduction:

The SSV16 series modular lube progressive divider valves can also be divided into the block -type lubrication divider, and its main principle is the use of a minimum of the overall design of the block of the dispenser group, each side exit 3 outlets.

The outlets are on the left and right side of the distributor with the same installation dimensions to different number of outlets, grease or oil spit and export derived merger increase the amount oil and lubrication manual, pneumatic or electric pumps connected simple composition, inexpensive small centralized lubrication system, also with larger centralized lubrication systems for single or double line distribution, connected as a secondary distributor for secondary distribution.

The SSV16 series progressive divider valve manifold combined with each piece of the middle elements, a piston is used to allocate and discharge grease diameter and the stroke of the piston determines the displacement of each of its stroke. The piston starts actions must be on one of the piston has been completed after the operation of the grease drainage, so that it can fully control the movement of the piston to ensure that the dispenser is able to continue to work.

To ensure correct installation, fittings and pipeline connections to be reliable, no leaks; element distributor in the assembly process, the environment must be kept clean and tighten with the specified tightening torque is too loose can cause leakage between the elements, tight damaged piece with the O-ring between the elements , which affects the use of the progressive block distribution.

Specification:

Model | Nominal pressure | Oil feeding flow | Starting pressure | Outlet port | Weight |

SSV-16 | 30Mpa | 0.2 ml/Cycle | ≤1.5Mpa | 16 | 3.5kgs |

Note: Using the medium for the cone is greater than 265 (25 ℃, 150g) 1/10mm, (NLGI0 # -2 #) of the grease. Such as the use of oil, viscosity grade than N68.

Code explanation:

SSV–16–K

SSV= SSV series of progressive divider valve manifold

16= Numbers of outlets, 16 outlet ports

K= With indicator; Without indicator if omit

SSV16 series of modular lube progressive divider valvedimensions:

Model | A | Max. Medium Flow Rate(ml/min) |

SSV-16 | 155 | 1000 |

1.Outlet injectors : φ6 (Installed with the blocks)

2. Maximum pressure loss 10-20bar when grease through the working cell at25 ℃ temperature.

2. Maximum pressure loss 10-20bar when grease through the working cell at25 ℃ temperature.

Model SSV16 series description:

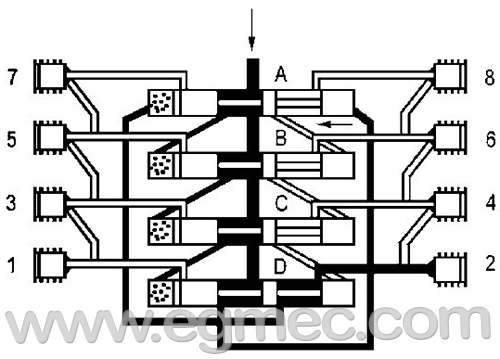

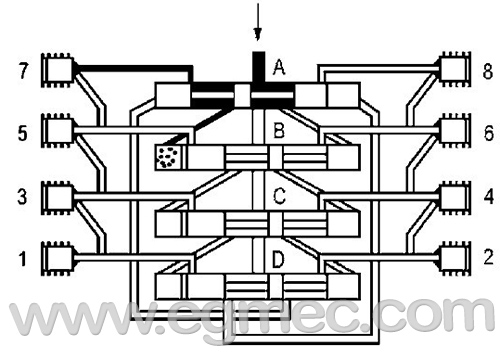

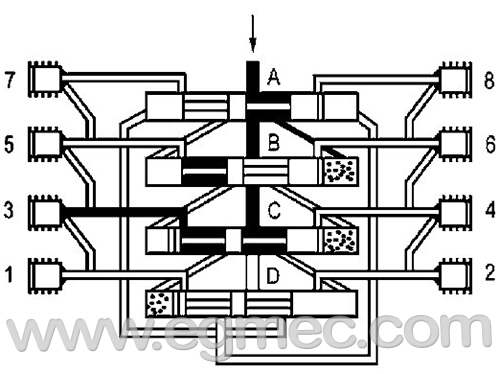

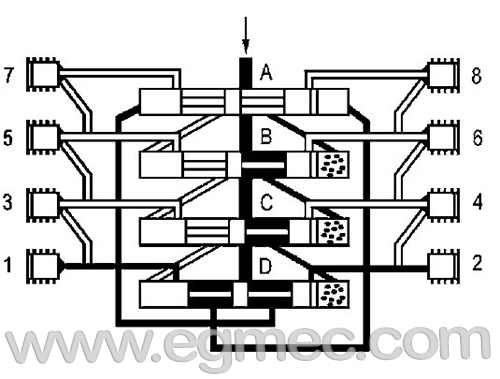

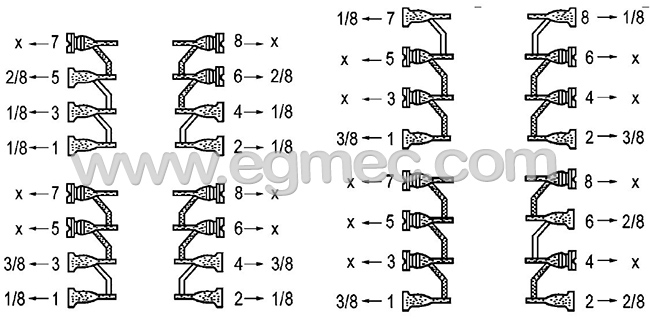

The grease/ oil enters into the distributor as per the direction of the arrow marked on the drawing above and transports to the end right of the piston A. The piston A moves to the left by the grease/oil pressure. The grease/oil in the position of piston A front left is transported to outlet 2 through internal passage of the house, reaches and lubricates the friction parts.

The right end passage connection of piston B is open while the piston A reaches the position of left end. The grease/oil flows into the right position of piston B and pushes the piston B moving to the left. The grease/oil store in left front of piston B is delivered to the outlet 7 through internal passage of the house.

The right end passage connection of piston C is open while the piston B reaches the position of left end. The grease/oil flows into the right position of piston C and pushes the piston C moving to the left. The grease/oil store in left front of piston C is delivered to the outlet 5 through internal passage of the house.

The right end passage connection of piston D is open while the piston D reaches the position of left end. The grease/oil flows into the right position of piston D and pushes the piston D moving to the left. The grease/oil store in left front of piston D is delivered to the outlet 3 through internal passage of the house.

The right end passage connection of piston D is open while the piston A reaches the position of left end. The grease/oil flows into the left position of piston A and pushes the piston A moving to the right. The grease/oil store in right of piston A is delivered to the outlet 1 through internal passage of the house.

When the piston B to D moves from the left to the right, according to the opposite direction above sequence of actions to complete a cycle and it will be restarting a new cycle

When the piston B to D moves from the left to the right, according to the opposite direction above sequence of actions to complete a cycle and it will be restarting a new cycle

How to use SSV16 series of modular lube progressive divider valves:

1.Recommended maximum through two-level distribution of lubricants in the system.

2. Outlets ports 1 and 2 should be never closed.

3. Always use the original injectors and outlets connection pipes.

4. Dismantling exchange the nozzle parts from of each side of the upper or the lower outlets.

5. The nozzle must be removed if the outlets need to be blocked, merge the volume of grease (Changing to lower outlet port), the M10x1 is used to block the injectors as per the drawing below for example.

2. Outlets ports 1 and 2 should be never closed.

3. Always use the original injectors and outlets connection pipes.

4. Dismantling exchange the nozzle parts from of each side of the upper or the lower outlets.

5. The nozzle must be removed if the outlets need to be blocked, merge the volume of grease (Changing to lower outlet port), the M10x1 is used to block the injectors as per the drawing below for example.

The SSV16 series of modular lube progressive divider valve faults and troubleshooting:

First check whether the lubrication pump is operation and lubricant to the main distributor if any device or any turned bearing is blocked, then open the allocator inlet connector lubricant overflow prove distributor is the root cause of the failure.

Connected to the inlet connector tightening, followed by open belongs bearing oil inlet connector lubricant overflow, which indicates the bearing is blocked. When the inner blocked in the distributor, it should replace with the new distributor case of emergency can be cleared under the following conditions.

1. The workplace should be clean.

2. Remove the inlet and outlet connectors.

3. Remove the screw plug of the piston bore two sides.

4. To push the piston out with a soft rod (Diameter less than 6mm, as far as possible the plastic rod ).

5. Cleaning of the distributor body with the compressed air blowing and.

6. Checking the distributor body flow passage holes with the fine wire (F1.5mm).

7. Cleaning and blowing distributor body again.

8. To replace the copper washers, reassemble the distributor.

9. Checking the new assembled distributor with a manual pump, then the distributor starting pressure can not be higher than 25bar. If the starting pressure is higher than 25bar, the distributor should be replaced.

2. Remove the inlet and outlet connectors.

3. Remove the screw plug of the piston bore two sides.

4. To push the piston out with a soft rod (Diameter less than 6mm, as far as possible the plastic rod ).

5. Cleaning of the distributor body with the compressed air blowing and.

6. Checking the distributor body flow passage holes with the fine wire (F1.5mm).

7. Cleaning and blowing distributor body again.

8. To replace the copper washers, reassemble the distributor.

9. Checking the new assembled distributor with a manual pump, then the distributor starting pressure can not be higher than 25bar. If the starting pressure is higher than 25bar, the distributor should be replaced.