Aluminum based coppper clad laminate

| Min. Order: | 200 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500000 per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Copper Clad Laminate, GPO-3, G11, G10, FR4 Material |

Product Detail

| Model No.: | ALCCL |

|---|---|

| Means of Transport: | Ocean |

| Place of Origin: | Zhejiang China (Mainland) |

| Brand Name: | LESON |

| Model Number: | Aluminum based copper clad laminate |

| Based material: | Aluminum |

| Withstand voltage: | 3.0KV to 5.0KV |

| Spot goods size(width and length): | 1040X1240mm(41"X49") |

| Thickness of Aluminum base: | 0.5mm to 3.2mm |

| Thickness of copper foil: | 35 micron,70 micron,105 micron,140 micron |

| Thickness of dielectric layer: | 100micron, 150micron |

| Thermal conductivity: | 1.0w/mk to 3.0w/mk |

| Production Capacity: | 500000 per month |

| Packing: | 200 sheets per pallet,wooden pallet |

| Delivery Date: | 10-18 days,according to the quantity of the order |

Product Description

We are a Chinese company that specializes in the production of composite materials for types of electrical and electronic more than twenty years, insulation and work piece to be certified as the best product in industries. We have 5 production lines and finishing department and can control the quality, delivery time and good price.

Thermal conduct Al-substrate CCL provides the advantages of high thermal conductivity ,Excellent solder heat endurance, Excellent Breakdown Voltage,reliability,Thermal conductivity is about five-ten times higher than the FR-4,PCB produced by the subtract can transfer heat, which is electronic components generate, thronging the substrate structure rapid conduct to the back-end cooling base or other cooling modules'- substrate CCL is a sandwich structure ,which includes layers of conductor ,insulator and metal base. In general, this insulator is made of epoxy resin and high thermal Conductivity filler. The products have been through a number of demanding for a long time environmental testing, access to international certification.

The Thermal conductivity is 1.0-3.0W/M.K,It can fit the demand of high end and mid-range products, with high cost performance. All products pass ROSH standard, have good property and meet low-carbon environmental trend.

.

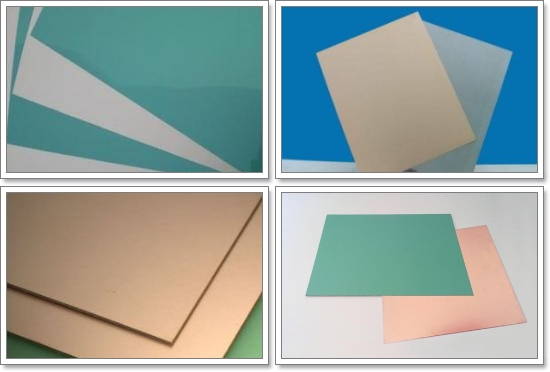

Material | Sandwich structure, which includes layers of conductor, insulator and metal base (Aluminum Based). |

Standard Size (mm) | 500×610mm,550×601mm,550×1220mm,550×1220mm,1000×1220mm,1100×1220mm |

Circuit Layer(copper foil ) | 18μm,35μm,70μm,105μm(Hoz,1oz,2oz, 3oz) |

Thermal Dielectric Layer Thickness | 100μm,125μm,150μm,(3mil,4mil,5mil,6mil) |

Thickness | 0.8mm,1.0mm,1.2mm,1.5mm,1.5mm,2.0mm |

Aluminum Substrate Type | 1100,1060,3003,5052,6061 Anodization |

Masking Film | PE,PET,PI |

Using scope | LED lighting, public lighting, Backlight module, outdoor LED display , Industrial electronics |

Flow Chart

Properties

Excellent thermal conductivity

Excellent Breakdown Voltage

ROSH compliance

Excellent solder heat endurance

Excellent mechanical properties

Excellent electromagnet

Can use external cooling device directly

High cost performance

Types

Type 1 General purpose. It is widely used in consumer lighting, outdoor LED display and backlight applications

Type 2 Standard thermal conductivity It is used in public lighting, digital, PC, Audio, Automotive applications

Type 3 High thermal conductivity. It is used in high power LED lighting, automotive applications, Industrial electronics

Type 4 High thermal conductivity, Low thermal resistance; it is used in high power application

The services you can enjoy from LESON

Pre-sale consultation After sale service

Ⅰ Quick response on inquires Ⅰ Immediate check of shipping status

Ⅱ w Consultation on product properties Ⅱ Guide on how to use products properly

Ⅲ Advice of material selection Ⅲ Effective solutions to customer complaints

Advantages

1.We are specialized in this industry for more than 20 years, So that ripe experience is gained and manufacturing engineering can be well controlled.

2. We can design and produce the workpiece according to the customers' drawings or samples.

3. We have our own professional and technical engineers to give you before and after sale technical support.

4. We can delivery the goods according to order on time.

5. We will try our best to offer a total solution for you.

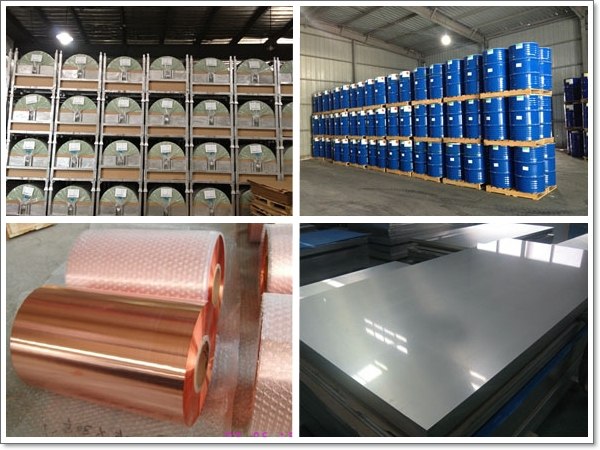

Raw material

Product Line

.

1. 5 Coating and laminate production lines

2. CNC machining center :5 sets CNC lathe: 5 sets, milling machines ,routing machines, threading machines, board cutting machine .

3. Technical team with experience of more than 10 years .4.Costomize different specifications and different quality grades as per customer's requirements .

Stock ,Package,Delivery

Professional and personalized package, rapid and promopt delivery.

If you have any question about our products , please feel free to contact us !