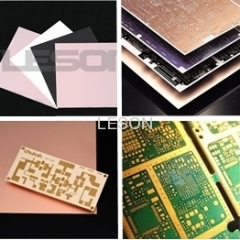

CEM-3 copper clad laminate

17.0~20.0 USD

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 15000pcs one month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Electrical Insulation Laminate Sheet, Copper Clad Laminate, PCB Used Insulation Sheet |

Product Detail

| Model No.: | CEM3 |

|---|---|

| Means of Transport: | Ocean |

| Peel strength min 1.31 N/mm: | Dielectric Voltage min 40KV |

| Production Capacity: | 15000pcs one month |

| Packing: | case and pallet |

| Delivery Date: | 20 days |

Product Description

CEM3 Copper clad laminate is made of epoxy resin, glass cloth and copper foil. It is of heat resistant, good

mechanical & electrical properties, high peel strength and chemical resistant, Suitable for making flame

resistant PCB of high-grade electronic equipment and auto-instrument line.

mechanical & electrical properties, high peel strength and chemical resistant, Suitable for making flame

resistant PCB of high-grade electronic equipment and auto-instrument line.

Peel strength (35μm copper foil) : min 1.31 N/mm

immerse resistance260℃,20S:no change

Dielectric Voltage:≥40KV

Dielectric Constant (1MHz):≤5.4

| General properties | ||||

| Testitem | Unit | Condition | Spec. | Typicalvalue |

| CEM-3CCL | ||||

| Tg | ℃ | DSC | ~ | 130 |

| Peelstrength | N/mm | 288℃,10s(cu17μm) | 1.05 | 1.5 |

| Flammability | ~ | UL94 | V0 | V0 |

| Volumeresistivity | MΩ.cm | C-96/35/90 | ≥106 | 2.0×108 |

| Surfaceresistivity | MΩ | C-96/35/90 | ≥104 | 2.0×106 |

| ArcResistance | S | D-48/50+D-0.5/23 | ≥60 | 135 |

| Dielectricbreakdown | kv | D-48/50+D-0.5/23 | ≥40 | 60 |

| Dielectricconstant(1MZ) | ~ | C-40/23/50 | ≤5.4 | 4.6 |

| DissipationFactor(1MZ) | ~ | C-40/23/50 | ≤0.035 | 0.017 |

| Thermalstress(Unetched) | ~ | 288℃,10s | Nodelamination Non-foaming | |

| Thermalstress(Etched) | ||||

| FlexuralstrengthLW | N/mm2 | A | ≥276 | 380 |

| FlexuralstrengthCW | ≥186 | 290 | ||

| WaterAbsorption | % | E-1/105+D-24/23 | ≤0.5 | 0.11 |

| ComparativeTrackingIndex | V | IEC60112 | 175~250) | |

| Remark:C=humiditycondition | ||||

| D=immersionconditiondistilledwater | ||||

| E=temperaturecondition | ||||