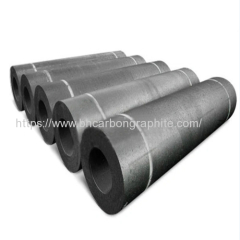

Graphite electrode RP 200mm with competitive price

| Min. Order: | 20 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 80000 Ton/Year |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Graphite Products |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | BENHONG |

| Grade: | RP (Regular Power), RP Graphite Electrode |

| Length: | 1500-2700mm |

| Resistance (μΩ.m): | 7-10 uΩm |

| Thermal Expansion: | 2.2-2.6 |

| Flexural Strength: | 8-10 Mpa |

| Application: | EAF (Electric arc furnace) /LF (Ladle Furnace) |

| ASH: | 0.5% Max |

| Current Load: | 22000-27000 A |

| Current Density: | 13-17 A/cm3 |

| Transport Package: | Wooden Pallets with Steel Strips |

| Production Capacity: | 80000 Ton/Year |

| Packing: | Graphite Electrodes are packed on wooden pallets |

| Delivery Date: | negotiate |

Product Description

Technical Data

| RP450 | |||||||

| Item | Unit | Item | Unit | ||||

| Resistivity | Electrode | μΩm | 7.0-10.0 | Bulk Density | Electrode | g/cm3 | 1.53-1.56 |

| Nipple | 4.0-4.5 | Nipple | 1.70-1.74 | ||||

| Modulus of Rupture | Electrode | Mpa | 8.0-10.0 | CTE (100-600℃) | Electrode | 10-6/℃ | 2.2-2.6 |

| Nipple | 19.0-22.0 | Nipple | 2.0-2.5 | ||||

| Young's Modulus | Electrode | Gpa | 7.0-9.3 | Current Load | A | 22000-27000 | |

| Nipple | 12.0-14.0 | Current Density | A/cm3 | 13-17 | |||

| Ash | % | 0.5 | Moment | N.m | 1600 | ||

| Nominal Diameter | Actual Diameter | Nominal Length(mm) | ||

| mm | Inch | Max(mm) | Min(mm) | |

| 75 | 3 | 78 | 73 | 1000 |

| 100 | 4 | 103 | 98 | 1200 |

| 150 | 6 | 154 | 149 | 1500-1800 |

| 200 | 8 | 205 | 200 | 1500-1800 |

| 225 | 9 | 230 | 225 | 1500-2100 |

| 250 | 10 | 256 | 251 | 1500-2100 |

| 300 | 12 | 307 | 302 | 1500-2100 |

| 350 | 14 | 357 | 352 | 1500-2400 |

| 400 | 16 | 409 | 403 | 1500-2400 |

| 450 | 18 | 460 | 454 | 1500-2400 |

| 500 | 20 | 511 | 505 | 1800-2700 |

| 550 | 22 | 562 | 556 | 1800-2700 |

| 600 | 24 | 613 | 607 | 2100-2700 |

| 650 | 26 | 663 | 657 | 2100-2700 |

| 700 | 28 | 714 | 708 | 2100-2700 |

| 750 | 30 | 765 | 759 | 2400-2700 |

| 800 | 32 | 816 | 810 | 2400-2700 |

Please send inquiry with your parameter requirements, I will make quotation within 1 hour.

Product Description

Graphite electrode, mainly petroleum BCK, needle BCK as raw material, coal pitch as binder, calcination, ingredients, kneading,molding, baking and graphitization, machining and made, which is released in electric arc furnace in the form of arc conductor of electricity to heat melting furnace charge.

Product Advantage

* High output,guarantee delivery date

Annual output: 80,000 tons

* Low resistivity,large bulk density, low internal defects

* Good thermal conductivity and electrical conductivity

* High mechanical strength, not easy to be broken;

* Low ash

(UHP:0.3%max; HP:0.2%max; RP:0.5%max)

* Low graphite electrode consumption.

* Good oxidation resistance

* Needle BCK content accounts for 80%,

Imported from Japan and South Korea

Application

1. Electric arc steelmaking furnace.

2. Ore-heating furnaces.

3. Resistance furnaces.

Company Information

Hebei Ben Hong New Material Technology Co., LTD is a leading manufacturer of graphite and carbon materials with a global reach. Our company has served the Iron & Steel, Aluminum, and other Metallurgical industries for over 30 years.

Our main products are graphite electrodes(RP 75mm-1200mm, HP 200mm-1000mm, UHP 200mm-800mm)and other carbon products, but also according to customer needs to produce high purity, high density, high strength graphite product.

The mission is to develop long-term, mutually rewarding relationships with customers and suppliers. We aim to continually provide excellent product quality, low overall cost, reliable delivery, and valued customer support. All the products that we make are ISO9001:2008 certified. With them, we have built long-term relationships to ensure a dependable supply to our customers around the globe.

Packaging & Shipping

normally our package is neutral standard export wooden support with twining plastic bags , to protect the all goods always are perfect when arriving clients' warehouse, no damage and no dirty during shipment .

Guidance of Using

Being hard and brittle ,artificialgraphite electrode shall be specially handled.Proper operationg may reduce the consumption and cost. graphite arc electrode

1. Professional tools should be used for hoisting graphite electrodes. It is strictly forbidden to use a crowbar to prevent impact damage during handling.

2. Graphite electrodes are prohibited from rain, snow and water, and should be kept dry. If it is found to be damp, it should be dried before use, the temperature should not exceed 100 ºC, and the drying time should not be less than 48h.

3. Do not stack near debris such as clay, slag, etc., so as not to pollute the surface of the graphite electrode and affect the conductive effect.

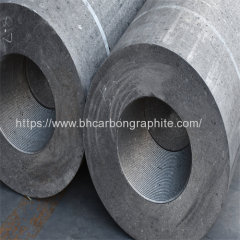

4. Before the graphite electrode is connected, carefully check whether the electrode connector hole is intact, whether the connector thread is damaged, and whether the connector bolt is lost. When the electrode is lifted, the electrode connector thread of the ground terminal should be prevented from being damaged.

5. Dust and debris in the joints and joint holes should be blown dry with compressed air.

6. Graphite electrodes must be tightly connected, and no tilt is allowed during connection. Torque wrenches should be used to prevent excessive force or too small, and the gap is not greater than 0.4mm.

7. The electrode holder should be clamped, not loose and in good contact, and no arc should be generated. Otherwise, the connection will be reddish, oxidized, thinned and broken. eaf graphite electrodes

8. If the electrode is lifted with a metal lifting plug, the thread in the joint hole must not be damaged. After lifting, the lifting plug should be unscrewed to prevent dust and debris from falling into the joint hole.

9. When the electrode lifting device of the electric furnace is running, it should be kept stable. After the furnace cover is repaired, check whether the furnace cover is positioned correctly. During smelting, refractory materials are used to close the furnace lid to prevent the oxidation of the upper electrode of the flame in the furnace. electric arc furnace graphite electrodes

10. The holder should be clamped outside the safety wire of the electrode connector hole area.

11. When distributing the molten pool, the big piece is at the bottom and the small piece is at the top. Do not place the charge with poor conductivity on the top. During melting, the unmelted charge should be handled in time to prevent the collapsed material from breaking the electrode.

FAQ

1.When can I get the price?

We usually quote within 24 hours after getting your detailed requirements, like size, quantity etc. If it is an urgent order, you

can call us directly.

2. What is your terms of delivery?

We accept FOB,CFR,CIF,EXW,etc.You can choose the most convenient way for you.Besides that,we can also shipping by Air and Express.

3.Product packaging? uhp graphite electrode

We are packed in wooden cases, or according to your requirements.

4.What's the dellivery?

The lead time is based on the quantity, about 10-15 days. For graphite product, apply Dual-use items license need about 15-20 working days.

5. Notice graphite electrode for arc furnaces

Please note that the price on alibaba is a rough price.The actual price will depends on raw materials, exchange rate ,wage and your order quantity.