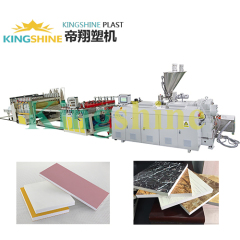

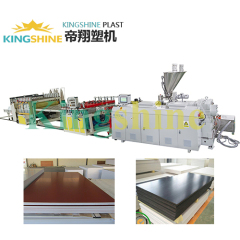

PVC/WPC Foam Board Production Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 80/156 |

|---|---|

| Means of Transport: | Ocean |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75 kw |

| Plastic Processed: | PVC |

| Screw Material: | SKD 11 |

| Screw Design: | Conical Twin Screw |

| Screw Diameter: | 80/156 |

| Power: | 75 kw |

| Applacation: | Foam Board |

| Output: | 400 kg/h |

| Warranty: | 1 year |

| Certification: | CE, ISO |

| Automatic Grade: | Automatic |

| Production Capacity: | 10 sets/month |

| Packing: | Container packing |

| Delivery Date: | 45 days |

Product Description

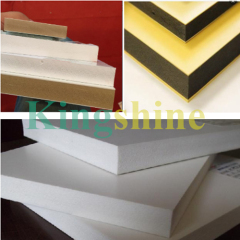

Description of PVC Foam Board

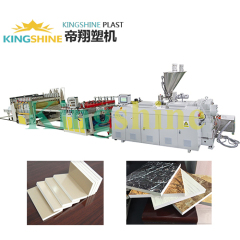

Applications of PVC Foam Board

1. Decoration board for kitchen cabinet. Furniture board, bathroom board

2. Building template, construction board

3. WPC indoor flooring base

4. Advertisement board

Advantages of PVC Foam Board

1. Strong and durable; Lightweight and easy to install; Not easy to scratch;

2. Will not rot, warp, delaminate, cup or twist;

3. Resistant to weather, shock and abrasion;

4. Salt water corrosion resistant;

5. Impervious to salts, insects and many chemicals, including some acids;

6. Doesn't mold; Can be worked just like wood;

7. Non-toxic; 100% recyclable; Fire-retardant (self-extinguishing);

8. Easy to clean; Virtually maintenance free;

Description of PVC Foam Board Production Line

PVC Foam Board Production Line is composed by conical twin screws extruder, mould head, calibration table, tractor, cutter, stacker. By adjusting the mold head, it could produce different thickness of foam board. We could offer the turnkey solution for PVC Foam Board project.

Production Process

Screw Loader for Mixer—High Speed Mixing Unit—Screw Loader for Extruder—Conical twin screw extruder—Mold Head—Calibration Table—Traction Machine—Cutting Machine—Stacker

NO | Machine Name | Quantity |

1 | Screw Loader for Mixer | 1 |

2 | SRL-Z serious High Speed Mixing Unit | 1 |

3 | Screw Loader for Extruder | 1 |

4 | SJSZ serious Conical Twin Screw Extruder | 1 |

5 | Mold head | 1 |

6 | Calibration Table | 1 |

7 | Tractor | 1 |

8 | Cutter | 1 |

9 | Stacking Table | 1 |

Technical parameters

Model | 80/156 | 80/173 | 92/188 |

Thickness (mm) | 4-40 | ||

Width (mm) | 1220, 1560, 1830, 2050 | ||

Extruder Motor (kw) | 75 | 90 | 110 |

Capacity (kg/h) | 400 | 600 | 700 |

High-end Electrical Components

Kingshine adopts high-end electrical components such as Schneider electric control system, ABB inverter, Siemens PLC, Siemens motor.

Certification

Our Company

Kingshine is one of the most professional plastic machinery manufacturing enterprises in China. The main production is PVC extrusion machinery:

1. SPC/LVT Flooring Production Line

2. PVC/WPC Door Board/Frame Production Line

3. PVC/WPC Foam Board Production Line

4. PVC Laminating/Marble Sheet Production Line

5. Mixer/Crusher/Miller

Kingshine pays attention to technological innovation, actively introduce advanced foreign technology, and constantly develop new products.

Our Service

1. Pre-sale service:

To provide information, market research and forecasting, provide consultancy, offers a variety of convenience and market service and so on.

Pre-sale service's main purpose is to assist the clients prepare the project planning and system requirements analysis, enable our products to maximize meet customer needs, but also to maximize customer investment play the comprehensive economic benefits.

2. After-sale service

1 Installation overseas

2 Provide all kinds of product formula, technology and chemical material manufacturer information

3 According to the customer's requirements, provide technical guidance

4 Technical training for employees of customers

5 Responsible for maintenance service, door to door service if necessary.

Contact Way