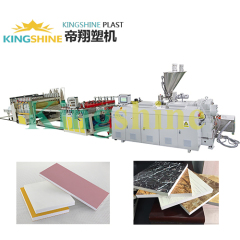

WPC PVC foam board production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 lines per year |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | KPM-FOAM1220 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | BENK |

| board wide: | 1220mm |

| board thickness: | 3-50mm |

| surface co-extrusion: | yes |

| board density: | 0.5-0.8 |

| board function: | construsion baord/furniture board |

| main extruder: | SJZ80/156 + SJZ65/132 |

| main motor: | 55KW + 37KW SIEMENS motor |

| inverter: | ABB |

| output: | 500KG |

| isntalaltion size: | 36X6X3M |

| Production Capacity: | 50 lines per year |

| Packing: | suitable sea transport package |

| Delivery Date: | 45 working days after receive deposit money |

Product Description

WPC PVC foam board making machine

WPC PVC foam board production line

1. about product

PVC and PVC wood composite crust foamed board( building board, WPC plate) extrusion line, is our company new product according to the market need, it could reduce the cost, recycling the material and reduce the pollution. The WPC board uses PVC, waste wood or agricultural plants, CaCo3 and other additives as main material, the boards are the newly products that can take place of the steel plate and bamboo plate.

The products features environment friendly, corrosion-resistance, damp-proof, moth-proof, distortion resistance, and can be processed under the same processing conditions as wood products, low cost, light weight, and could recycle more than 30 times, therefore they have wide and popular application in the future.. The waste woods and plastic can be recycled to produce WPC boards, which not only good to the environment, but also "turn wasted into wealth".

PVC and WPC crust foamed boards also use widely as building board, tools board, furniture, mould for block, packaging ,recycling box, advertisement plate, show plate, business plate, roof, ship profile, etc. this product have specifications as weather resistance, resistance germ, corrode, cloudy, ant, fire, elect, worms, mice, ultraviolet ray, etc. also could keep temperature, use long times.

This production line adopts special designed SJZ80 conical twin screw extruder, uses DC speed regulator, imported world famous brand temperature controller, has the advantages of large speed regulating scope, accurate temperature control, easy and reliable operation. The auxiliary units consist of vacuum foamed stand, haul-off, cutting machine and stacker, etc. It is equipped with large forced cooling device to ensure good foamed result. The caterpillar type haul-off adopts précised reduction and frequency inverter, features reasonable structure; large hauling force and stable haul off. The cutting machine has the characteristics of reliable and precise working, accurate cutting, etc. The stacker is matched with movable trolley and special designed rubber protection shield, has the advantages of damage free to the product, easy and convenient operation, etc. The auxiliary units are able to use the PLC control, which is stable and reliable.

2, reference pics:

extruder:

extrusion & forming die

haul-off

cutter

main technical parameter:

Model | Unit | SJSZ80/156 | SJSZ92/188 | SJSZ80/156+ SJZ65/132 | SJP92/32 |

Product width | mm | 1220 | 1220 | 1220-1600 | 2050 |

Product thickness | mm | 3-20 | 3-50 | 3-30 | 3-20 |

Max. extrusion capacity | Kg/h | 350 | 500 | 600 | 450 |

Power of extruder | KW | 75 | 110 | 120 | 75 |

3, BENK's Service:

3.1 Technical documents

All the symbols on the equipments should be in English. Seller is responsible to provide general layout plan, electric plan, installation direction, and manual book in English to Buyer on time.

3.2. Arrangement for inspection, installation and testing work

a. After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.

b. BENK will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

c. The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD80 per day for each engineer.

d. Engineer will give free training lessons to labors in buyer's factory.

e. If buyer doesn't request installation and commissioning by Seller's engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

3.3. Quantity and quality guarantee

a. Quantity/Quality Discrepancy to destination port during transportation:

In case of quality/quantity discrepancy to destination port in transportation, customer should file claim within 30 days after the arrival of the goods at port of destination. Insurance company and shipping company will be responsible for any discrepancy of the goods caused by shipping company and other transportation organization and/or post office.

b. Guarantee period and after-sales services: 13 months since date of bill of loading

During this guarantee period, BENK will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, BENK will provide the buyer spare parts at cost price.

c. Long-term service:

BENK will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

We thank you for your inquiry and would be pleased to receive your order soon.

ZHANGJIAGANG CITY BENK MACHINERY CO., LTD.