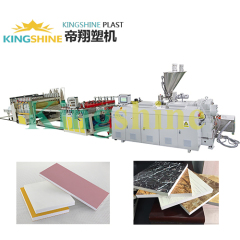

PVC WPC foam board production line

120000.0~160000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100 sets per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | PVC Pipe Production Line, PVC Profile Extrusion Line, Parallel Twin Screw Extruder, WPC Profile Extrusion Line, Single Screw Extruder |

Product Detail

| Model No.: | JBD-MSB80 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | JBD |

| Power: | 75kw |

| Capacity: | 250-300kg/h |

| width of template: | 915-1220mm |

| thickness of template: | 5-20mm |

| Production Capacity: | 100 sets per year |

| Packing: | wooden case |

| Delivery Date: | 50 working days |

Product Description

WPC foam board which gather advantages of both timber and plastic, it not only has natural timber appearance but also conquers natural timbers shortcomings, with features of corrosion resistance, moisture resistance, eat resistance, high dimension stability and never crack. besides, it has higher rigidity compared with pure plastic, with similar machining character as timber, can be cutted, painted, conglutinated, and fixed with nail or bolt

WPC foam board production line adopts our original wood and plastic technology and formula, it can make wood-plastic sheets with PVC and wood powder. The products are widely used in high-grade car interior decoration, advertising board , base material and decoration materials for hotels, restaurants and entertainment .

WPC foam board production line adopts our original wood and plastic technology and formula, it can make wood-plastic sheets with PVC and wood powder. The products are widely used in high-grade car interior decoration, advertising board , base material and decoration materials for hotels, restaurants and entertainment .

Main technical parameters of WPC foam board making line

Auxiliary machine model | JBD-MUB915 | JBD-MSB1220 |

Product size (thickness) | 915 | 1220 |

Haul-off range | 150 | 150 |

Hauling force | 30KN | 40KN |

Hauling speed | 0.5-3m/min | 0.5-3m/min |

Total installed power | 250kw | 250kw |

Cooling water | 9 m³/h | 12 m³/h |

Compressed air | 0.6MPa | 0.6MPa |