WPC PVC Door Board Extruder Machinery

| Min. Order: | 1 Short Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 80/156 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75kw |

| Capacity: | 250-450kg/hr |

| Power System: | Siemens Electric system |

| Control System: | Siemens PLC sysytem |

| Inverter: | ABB |

| Contactor: | Schneider |

| Machine Color: | Customer Choice |

| Weight: | 18Tons |

| Thickness: | 3-25mm |

| Mechanical line speed: | 0.6-6m/min |

| Daily Capacity: | 6-8Tons |

| Production Capacity: | 20sets/month |

| Packing: | Plastic film or wood |

| Delivery Date: | 45days |

Product Description

Our Company

Kingshine

-Over 20 years' experience in manufacutre machines

-Over 40 countries' customers in the world

-Over 3000 machines are using

-Over 50 lines send to the world per year

Kingshine Machinery is dedicated to various solutions in Plastic Machine customized to customs satisfy.

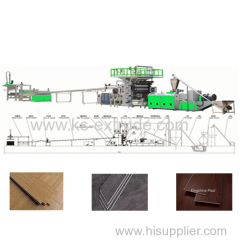

Producing Description:

PVC profile extrusion machine can produce all kinds of profile, for example, window, door

and door frame, pallet, cladding of outdoor wall, faciliry of ourside park, floor etc. Output profile

is Wood Plastic Composite(WPC) or Plastic UPVC.

Customer viewing

Production

WPC Introduction:

As a new material to replace wood, wood plastic composite is widely used in fields of building decoration

and outdoor building materials, such as edge and corner lines, fence of flowers nursery, skirting board,

ceiling line, blind window, stair railing, decorative wall board, outdoor pavilion and so on.

Most interior and exterior decorative building materials can be made by using wood plastic composite.

Particularly, wood plastic composite can be used in kitchen and washing room for its waterproof and fireproof functions which the raw wood does not have.

At present, wood plastic composite has already drawn extensive attention in the world and is praised as new material which will have board developing prospect.

Work Flow

Main technical parameters:

Extruder Type | SJZ51/132 | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 |

Main Motor Power | 18.5kw | 30kw | 37kw | 55kw | 110Kw |

Production capacity | 80-120kg/h | 100 -180kg /h | 150-220kg/h | 200-350kg/h | 550- 750kgh |

SJZ Series Conical Twin Screw Extruder→ Die mould → Vacuum Calibration Table →

QYQ series Haul-offs and Cutting Machine Unite →DF series Stacker → Control cabinet

(Note: Other Auxiliary Machine, such as crusher, mixer, will be provided according to client's requirements)

Service

Pre-sale service

To provide information and market research,to provide consultation,to provide many kinds of

conveniences and market service,etc.

The main purpose of pre-sales service is to help customers make the project planning and

system requirements analysis. Make our products maximum to meet clients' requirements.

Also play the greatest overall economic benefits of customers' investment.

After-sale service

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support

-To provide installation and test for the machine.

-To provide formulas and technology of relevant products.

-To provide information of chemical material manufactories.

-To provide technical training for clients' employees.

Packaging & Delivery

Packaging Details:

Standard shipping package for WPC Door Board making machine.

Port:

Shanghai

Lead Time :

Quantity(Sets) | 1 - 1 | >1 |

Est. Time(day) | 45 | To be negotiated |

Main composition

Item | Quanlity |

SJSZ- XX Twin Screw Extruder with Automatic Feeding System | 1Set |

Die Mold & Stock Mold | 1Set |

Vacuum Calibrarion Table | 1Set |

Haul-off and Cutter Unit | 1Set |

Stacker | 1Set |

Electric Control System | 1Set

|