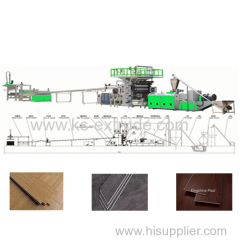

SPC PVC Vertical four roller Production Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 80/156 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75kw |

| Capacity: | 250-450KG |

| High Configuation: | PLC control system |

| Siemens system: | deeply embossing |

| internation electric parts: | ABB inverter |

| Patent Laminate device: | Automatic Sheet collector |

| Daily Capacity: | 28-35T |

| Machine Color: | Customer Choice |

| Mechanical line speed: | 1-6m/min |

| Contactor: | Schneider |

| Density: | 1.9~2.1g/cm³ |

| Embossing Depth: | 0.1-0.5mm |

| Production Capacity: | 20sets/month |

| Packing: | Plastic film or wood |

| Delivery Date: | 45days |

Product Description

About Kingshine Plast

Jiangsu Kingshine Plastic Machinery Co., Ltd. is one of the most professional

plastic machinery manufacturing enterprises in China.It is located in Wuxi,

Jiangsu Province.The traffic is convenient,nearby the airport and train station.

Kingshine pay attention to technological innovation, actively introduce

advanced foreign technology, and constantly develop new products.

-Over 20 years' experience in manufacutre machines.

-Over 40 countries' customers in the world.

-Over 3000 machines are using.

-Over 50 lines send to the world per year.

Kingshine Machinery is dedicated to various solutions in Plastic Machine customized to customs satisfy.

Our Factory Environment

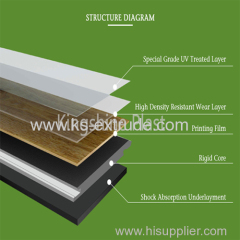

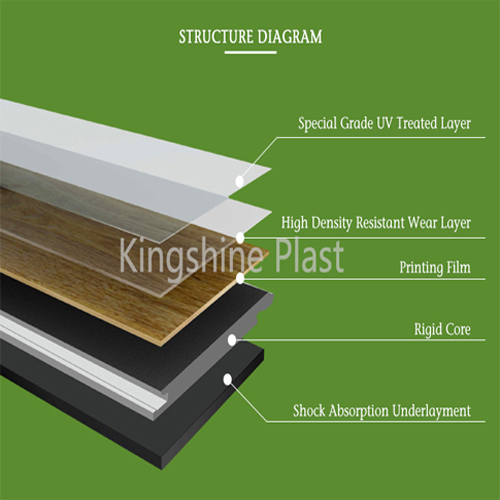

The Structure of Production

Running of Machine

Work Flow

Process 1 : Mixture

According to the ratio of raw materials for automatiic weighing, high-speed

mixer hot mix (thermal mixing temperature: 125 ℃, role is the mixing of various

materials, eliminate the moisture in the material) - > enter cold mix (material cool

down to prevent caking and discoloration, cold mix temperature: 55 ℃).- by cooling

mixing of materials;

Process 2: Extrusion

Join the twin screw extruder, heated extrusion - into the sheet forming,

extrusion molding pieces.After four roll calender, base material to decide

to stick color film, thick stick wear-resisting layer - cooling - cutting;

Process 3: UV tempering

Surface UV - tempered, tempering hot water temperature: 80 ~ 120 ℃;

The cold water temperature: 10 ℃)

Process 4: Self-finished Product inspection

Cutting, notching, trimming, chamfering to inspection, packaging.

Final Production

Product Application

1. Elasticity: one-step SPC floor, different from the stone, tiles and other hard materials,

imitation stone and wooden surface floor gives a more comfortable experience.

2. Taking into consideration of the health and anti-skid, SPC floor has a unique anti-skid

ability, while ensuring adequate resistance to dirt, easy to clean.

3. Anti-mildew insects: SPC floor, wear durable, good shrinkage stability; surface is pure

PVC wear layer, high wear resistance. And wood flooring is easy to deformation and with

high risk of raw insects.

4. Non-toxic: the latest environmentally friendly technology, low cost, high stability, zero formaldehyde.

Packaging & Delivery

Packaging Details:

Standard shipping package for PVC WPC Foam Board making machine

Port:

Shanghai

Lead Time :

Quantity(Sets) | 1 - 1 | >1 |

Est. Time(day) | 45 | To be negotiated |

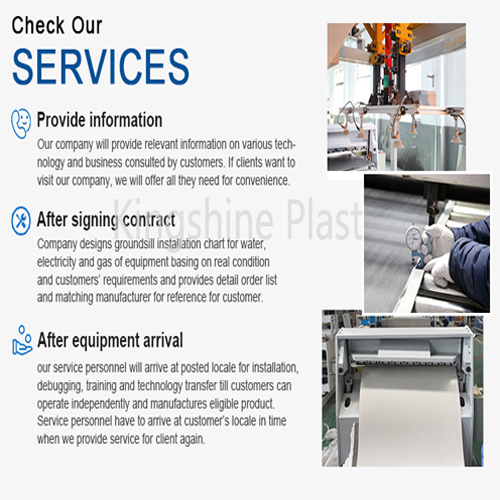

Technology support

-To provide installation and test for the machine.

-To provide formulas and technology of relevant products.

-To provide information of chemical material manufactories.

-To provide technical training for clients' employees.

Service

Pre-sale service:

-To provide information and market research.

-To provide consultation.

-To provide many kinds of conveniences and market service,etc.

The main purpose of pre-sales service is to help customers make the project

planning and system requirements analysis. Make our products maximum to

meet clients' requirements. Also play the greatest overall economic benefits

of customers' investment.

After-sale service:

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information

of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements.

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary

circumstance.