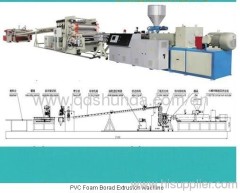

pvc foam board extruder machinery

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10 sets every month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

| Main Products: | Plastic Sheet Extrusion Machine, PVC Sheet Extrusion Line, PVC Profile Extruding Machine, PVC Foam Board Extrusion Line, PP Pipe Production Line |

Product Detail

| Model No.: | 80/156 |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | shunlida |

| Power: | 150Kw |

| Model Number: | SJSZ92 |

| Product type: | plastic plates |

| Processing type: | Extruding machine |

| PVC foamed sheet machine: | PVC foamed sheet |

| Certification: | CE |

| Main motor power: | 150Kw |

| screw structure: | double-screw |

| Plastic processed: | PVC |

| capacity: | 300-600kg/h |

| Condition: | new |

| Production Capacity: | 10 sets every month |

| Packing: | packing in case wood |

| Delivery Date: | within 60 working days after 30% payment |

Product Description

pvc foam board extruder machinery

This production line adopts our original wood and plastic technology and formula, it can make

wood-plastic sheets with PE/PP and wood powder. The products are widely used in high-grade car interior decoration, advertising board , base material and decoration materials for

hotels, restaurants and entertainment .

This machine adopts the SJMS80/156 conical twin-screw extruder,,it also can be equipped with the SJMS92/188 wood-plastic conical twin-screw extruder. The calibrating machine, traction machine and plate shearing machine are designed uniquely.

The three rollers are mirror surface grinding and driven independently.The machine is equipped with the edge-cutting device for the waste material and the water tank to control the constant temperature

of the three rollers.

The wood-plastic plate: product width 1000-2000mm, product thickness 2-20mm.(can be customized)

Name

Craft process

Materials preparing →spring loader →extruder →mould →calibrating device →roller cooling bracket →Double roller tractor device →Edge-cutting device →Across cutter device →Conveying device