PVC WPC Foam Board

| Min. Order: | 1000 Square Meter |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000000sqm/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 80/156 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75 |

| Capacity: | 400 |

| Best service: | Siemens electric system |

| High capacity: | PLC control system |

| PVC foam board extrusion line/production line/machine/machinery: | Highest Tech |

| Production Capacity: | 1000000sqm/month |

| Packing: | box |

| Delivery Date: | 60days |

Product Description

WPC PVC Foam Board

Product Type:PVC Crust Foam Board

Place of origin:China

Model :PVC

PVC Crust Foam Board:

1 Width: 1220mm,

2 Length: 2440mm or as per your requirement.

3 Thickness: 4mm,6mm,8mm to25mm

Product introduction

PVC Crust Foam Board is easy to clean and maintain, a good deep-drawing quality, light weight, but strong. Model can be applied to construction, office furniture, walls, indoor and outdoor decoration, air conditioning ducts, windows and ceiling.

PVC Crust Foam Board is organic and inorganic combination of the preparation through the series of advanced technologies, the extrusion foam molding, a wood-plastic sheet, extrusions, bar. As the use of the raw materials and production processes do not use glue bonding, no formaldehyde, ammonia, trichloroethylene, and other harmful substances. And has anti-UV, coloring good performance, heat insulation, noise, and alkali resistance, insulation, fire-retardant, anti-corrosion, anti-mildew and anti- pest, moisture resistance, sawing, planing, nails, a good machining performance, and 100% recovery, is a jewel instead of the traditional green timber new material. Compared to PVC free foam board, PVC crust foam board has the better advantages on hardness , cleaning, strength and so on.

PVC Crust Foam Board Features:

1. Feather light, non-absorb water, fire retardant and self-extinguishing

2. Foam Board is sound insulation, heat insulation, noise absorption, heat preservation and corrosion prevention.

3. Weather proof, vandal proof, and can be shaped, moulded, painted and screen printed.

4. Non-warping and stain proof.

5. Non-corrosive, non-toxic and chemical resistant.

6. Tough, rigid with a high impact stregth.

7. PVC Crust Foam Board is easy to clean and maintain.

PVC Crust Foam Board Application:

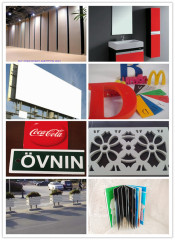

1.Advertisement: exhibition & display, digital printing, silk screen printing, engraving materials, sign board, etc.

2.Furnitureoffice furniture, cabinet, bath cabinet, etc.

3.Finishing Materialdecorative sheets, storage racks, room segments, etc.

4.Industrial Application: thermoforming products, refrigeratory warehouse project, environmental protection.

| WPC boards are available with various names like 'Construction boards', 'Crust foam boards', 'Calcium boards', 'WPC shuttering boards' 'WPC MDF boards', WPC Plates, PVC foam boards, WPC sheets, WPC panels, WPC formwork panels etc. in global markets. WPC boards can be produced with flexible density range varies from 400 kg/cum to 600 kg/cum. Another important characteristic is the surface density of this product and which also can be adjusted between a range of 55 shore D to 85 shore D surface hardness. Formulations play a major role in making WPC boards and that is the master key which allows it to be known by different names as above. Boyu provides formulation services as well as manufacture readymade compounds for WPC boards. Saw mill dust, wood powder, Virgin & recycled plastics and additives are key components for making these composite boards. | |

| These boards are covering a large application area starting from interior grade boards being used for making furniture, kitchen cabinets, kitchen shutters. Taking further, these boards are being used for making temporary shelters for government housing projects, construction site pavilions/shelters, low cost housing projects and other road and building projects. | |

Importantly in comparison to conventional plywood and MDF boards, WPC board doesn't need a compulsory lamination for end user applications. These boards can be directly applicable with beautiful and technical harden surface properties in compare to even high pressure laminate applied surfaces. WPC PVC foam boards can be directly printed and UV coated for surface decoration. Ultraviolet treatment on the surface gives a long life in compare to HPL coated surfaces of MDF, Particle boards and Plywood. Moisture proof structure of WPC boards gets more mileage with Printing and UV coating. | |

| Versatile product thickness ranges from 4 mm to 20 mm and various colours can be made available for variety of direct applications again. These solid or plain coloured WPC boards are surely replacing the product coated with HPL (high pressure laminate conventionally known as Sunmica and Formica as generic names). | |