Single Cylinder Hydraulic Cone Crusher

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 20-100 sets per month |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | HC430 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | MKD |

| Certificate: | ISO9001-2000; CE |

| Production Capacity: | 20-100 sets per month |

| Packing: | Nude |

| Delivery Date: | 20-30 working days |

Product Description

Brief Introduction of Single Cylinder Hydraulic Cone Crusher:

1.Intelligentized automatic control system offers a very safe and stable adjustment and control mode. Special Single Cylinder hydraulic adjusting device makes the crusher adjustment and safeguard very simple and reliable.

2.Intelligentized control system provides the crusher with a set of overload protection system. When the iron falls into the crushing chamber, crusher can deal with it by itself in a safe way, and therefore ensure its safe running and the safety of the operator.

3.The supporting structure of our cone crusher makes the up-down adjustment and movement of the main shaft assembly very simple. The operator can adjust or modify the discharge opening size at any time.

4.Intelligentized control system makes all the executive mechanism of the crusher bring out the best working efficiency and all the running status are monitored and adjusted all the time.

5.Multi-chambers and Multi-eccentric structures ensure the crusher to deal with the bigger application range. Replacing different abrasive liner plates and suitable rings can change the application range of crusher, which is simple and reliable.

6.The structure of single cylinder makes the outline of crusher compact and smooth. The total weight of crusher is light and the capacity is big.

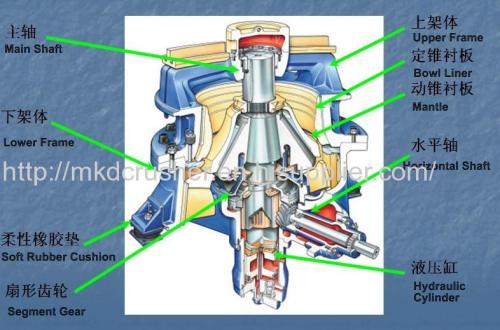

Inner structures & working principle:

When the crusher works, the rotational movement of the electric motor pushes the eccentric shaft to move through pushing the movement of transmission shaft and circular arc bevel gear. The mantle part rotates round a fixed point under the movement of the eccentric sleeve, which therefore makes the mantle sometimes be close to and sometimes be away from the surface of the bowl liner and finally crushes the raw materials inside the crushing chamber under the force of impact, squeeze and break. And then the crushed materials are discharged from the discharge opening by the weight of themselves.

With deeper crushing chambers and bigger feeding sizes, especially suitable for crushing hard rock and can get fine products.

The design of H&S types of cone crushers is rooted in primary gyratory crusher, with advantages of higher reliability and good at dealing with high strength's crushing operation. They have deeper crushing chambers and bigger feeding sizes. H-type of cone crusher can be adjusted to a smaller discharge opening, which is particularly suitable for the crushing requirement of fine product production, high capacity and high quality. As wide adjustable discharge opening range, good shapes of final products can be gotten. They also can be used as the medium crushing equipment according to the actual situation of the project.

Main shaft is supported by the upper and lower ends, using the closed type of rack with beams (called upper arm support). The structure is sturdy and reliable through finite element analysis by the computer and the technology of stress simulation

The reliability of H&S series single cylinder hydraulic cone crushers is also benefit from the simple single cylinder hydraulic system. A hydraulic cylinder can adjust the position of the main shaft, pass the crushing force, adjust the discharge opening, and realize the chamber clearance, iron-discharged and over load protection functions, at the same time provides a good foundation condition for automatic control. More functions of production process control and operating optimization have been realized by ASRI intelligent discharge opening control system. Due to the large diameter of the single hydraulic cylinder, the hydraulic system works at a low pressure (less than 5Mpa), while hydraulic systems and components are designed and optioned at a higher pressure standard, which, therefore, has greatly improved the safety and reliability of the hydraulic system.

Technical Data of HC430 Single Cylinder Hydraulic Cone Crusher:

HC430 (EC) Single Cylinder Hydraulic Cone Crusher

1) Max. Feeding Size: 185mm

2) Capacity: 37-219tph

3) Motor Power: 132kw

4) Range of discharge opening: 5-38mm

5) Overall Dimension: 1741*1360*2570mm

6) Weight: 9.2t

HC430 (M) Single Cylinder Hydraulic Cone Crusher

1) Max. Feeding Size: 90mm

2) Capacity: 64-162tph

3) Motor Power: 160kw

4) Range of discharge opening: 10-32mm

5) Overall Dimension: 1741*1360*2570mm

6) Weight: 9.2t

HC430 (MC) Single Cylinder Hydraulic Cone Crusher

1) Max. Feeding Size: 115mm

2) Capacity: 57-173tph (CSS=10mm, Capacity is 27)

3) Motor Power: 160kw

4) Range of discharge opening: 10-32mm

5) Overall Dimension: 1741*1360*2570mm

6) Weight: 9.2t