Hydraulic Cone Crusher for sale

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Cone Crusher, Jaw Crusher, Impact Crusher, Crushing Plant, Sand Washer |

Product Detail

| Model No.: | SMH Series |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Ore |

| Type: | Crusher |

| Brand Name: | sanme |

| Delivery Date: | 30 days |

Product Description

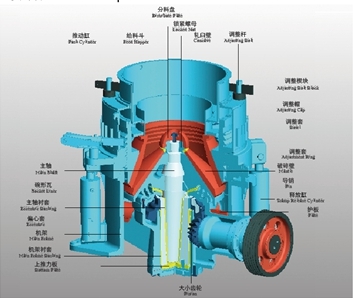

SMH Series Cone Crusher

SMH series hydraulic cone crusher get to world advanced level, is designed and made through absorbing world advanced crushing

technology.It is widely used in metallurgical, aggregate, building material industries, it is suitable for crushing varies of hard and

above mid hard ores and rocks.

Features and Benefits:

◎ Reasonable structure, advanced crushing principle and technical data, reliable work and low cost.

◎ Strong crushing ability, high efficiency productivity, high capacity.

◎ Hydraulic system is reliable, provide safe and effective overload protection.

◎ Types of crushing cavity are for wide range of product size requirement.

◎ Use hydraulic adjustment and hydraulic clean cavity setting, much increase automation.

Main Components

Standard Head Cone Crushers

Technical Data

Model | Max Feeding Size (mm) | Discharge Range (mm) | Motor Power (kw) | Capacity(t/h)_open circuit,closed discharge(mm) | |||||||||||

9 | 13 | 16 | 19 | 22 | 26 | 32 | 38 | 51 | 63 | 76 | 89 | ||||

SMH120C | 160 | 22-32 | 75-90 | 120 | 130 | 150 | |||||||||

SMH120M | 130 | 13-26 | 65 | 85 | 100 | 120 | 130 | ||||||||

SMH120F | 50 | 9-19 | 40 | 60 | 80 | 90 | |||||||||

SMH180C | 180 | 22-32 | 132-160 | 185 | 195 | 215 | |||||||||

SMH180M | 140 | 13-32 | 90 | 115 | 135 | 160 | 180 | 200 | |||||||

SMH180F | 60 | 9-22 | 60 | 80 | 100 | 120 | 140 | ||||||||

SMH250C | 260 | 26-51 | 160-220 | 250 | 290 | 340 | 395 | ||||||||

SMH250M | 150 | 16-38 | 125 | 140 | 165 | 220 | 275 | 330 | |||||||

SMH250F | 80 | 9-22 | 70 | 90 | 115 | 130 | 150 | ||||||||

SMH 350EC | 315 | 38-64 | 250-280 | 555 | 649 | 766 | |||||||||

SMH350C | 230 | 26-64 | 366 | 430 | 468 | 929 | 657 | ||||||||

SMH350M | 205 | 22-52 | 266 | 299 | 348 | 393 | 451 | ||||||||

SMH350F | 180 | 16-38 | 188 | 212 | 234 | 267 | 305 | 337 | |||||||

SMH 550EC | 450 | 38-89 | 400 | 890 | 1179 | 1380 | 1475 | 1566 | |||||||

SMH550C | 350 | 31-76 | 800 | 850 | 1100 | 1288 | 1398 | ||||||||

SMH550M | 320 | 25-63 | 612 | 735 | 815 | 990 | 1137 | ||||||||

SMH550F | 268 | 19-52 | 376 | 412 | 500 | 620 | 725 | 867 | |||||||

Stort Head Cone Crushers

Technical Data

Model | Max Feeding Size (mm) | Discharge Range (mm) | Motor Power (kw) | Capacity(t/h)_open circuit,closed discharge(mm) | ||||||||||

3 | 5 | 6 | 9 | 13 | 16 | 19 | 22 | 26 | 32 | 38 | ||||

SMH120DC | 70 | 6-19 | 75-90 | 59 | 68 | 96 | 110 | 130 | ||||||

SMH120DM | 51 | 5-16 | 45 | 59 | 68 | 96 | 110 | |||||||

SMH120DF | 35 | 3-13 | 30 | 45 | 50 | 65 | 90 | |||||||

SMH180DC | 70 | 6-19 | 75-90 | 72 | 90 | 108 | 131 | 158 | ||||||

SMH180DM | 51 | 5-16 | 68 | 76 | 95 | 118 | 145 | |||||||

SMH180DF | 35 | 3-13 | 70 | 82 | 95 | 120 | ||||||||

SMH250DC | 89 | 9-22 | 160-220 | 100 | 120 | 145 | 175 | 210 | ||||||

SMH250DM | 70 | 6-16 | 82 | 105 | 130 | 160 | ||||||||

SMH250DF | 54 | 5-16 | 80 | 90 | 110 | 135 | 160 | |||||||

SMH 350DEC | 133 | 13-25 | 250-280 | 280 | 310 | 340 | 370 | 390 | ||||||

SMH350DC | 133 | 10-25 | 210 | 280 | 310 | 340 | 370 | 390 | ||||||

SMH350DM | 89 | 6-19 | 130 | 168 | 215 | 260 | 290 | |||||||

SMH350DF | 70 | 6-13 | 130 | 168 | 215 | |||||||||

SMH 550DEC | 203 | 16-25 | 400 | 510 | 600 | 630 | 680 | 720 | 750 | |||||

SMH550DC | 178 | 13-25 | 455 | 488 | 552 | 600 | 620 | 698 | ||||||

SMH550DM | 133 | 10-19 | 355 | 420 | 460 | 530 | 545 | 580 | ||||||

SMH550DF | 105 | 6-16 | 220 | 310 | 375 | 428 | 482 | 497 | ||||||

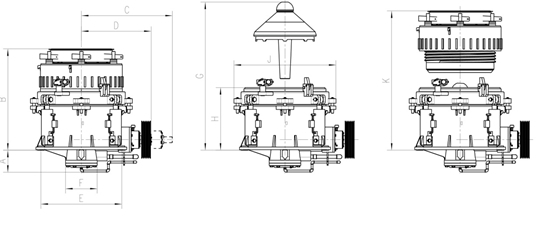

Clearance Dimensions and Weight

Technical Data

Clearance Dimensions and Weight | Unit | Crusher Specifications | |||||

SMH120 | SMH180 | SMH250 | SMH350 | SMH550 | |||

Distance between rack bottom and oil pipeline at the bottom | A | mm | 377 | 263 | 593 | 850 | 1020 |

Distance between rack bottom and hopper top | B | mm | 1737 | 1810 | 2119 | 2496 | 3290 |

Horizontal space at the time of drive shaft disassembling | C | mm | 1773 | 1833 | 2396 | 3510 | 4420 |

Distance between centre line of crusher and outside end surface of drive shaft | D | mm | 1191 | 1191 | 1566 | 2465 | 2968 |

Size of bolt position | E×E | mm | 1380 | 1380 | 1766 | 2260 | 2490 |

Diameter of bottom cap | F | mm | 540 | 400 | 686 | 800 | 927 |

Vertical space at the time of main axis disassembling | G | mm | 2538 | 2233 | 3353 | 4065 | 5860 |

Distance between rack bottom and top of supporting ring | H | mm | 1074 | 1147 | 1324 | 1705 | 2431 |

Max diameter of supporting ring | J | mm | 1740 | 1740 | 2258 | 3620 | 3721 |

Vertical space at the time of adjustment set disassembling | K | mm | 2387 | 2460 | 2937 | 3755 | 4576 |

Total Weight | kg | 12500 | 13500 | 24200 | 45850 | 86700 | |

Product Gradation Table (%passing through square mesh depending on the setting)

6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 28 | 32 | 38 | 45 | 51 | |

2 | 38 | 25 | 21 | 15 | 11 | 10 | 9 | 7 | 5 | 4 | 3 | 3 | 2 |

4 | 64 | 45 | 38 | 33 | 25 | 20 | 15 | 13 | 10 | 8 | 6 | 5 | 2 |

6 | 77 | 62 | 56 | 41 | 34 | 29 | 23 | 18 | 14 | 11 | 7 | 6 | 5 |

8 | 92 | 79 | 69 | 55 | 42 | 35 | 27 | 22 | 17 | 14 | 10 | 9 | 8 |

10 | 99 | 90 | 78 | 66 | 51 | 45 | 35 | 30 | 25 | 18 | 16 | 13 | 10 |

13 | 100 | 95 | 88 | 78 | 62 | 55 | 43 | 36 | 28 | 23 | 18 | 15 | 14 |

16 | 100 | 96 | 88 | 77 | 65 | 53 | 46 | 37 | 29 | 23 | 20 | 17 | |

19 | 100 | 95 | 85 | 76 | 67 | 55 | 44 | 37 | 27 | 23 | 20 | ||

22 | 100 | 92 | 83 | 76 | 65 | 53 | 45 | 35 | 28 | 23 | |||

25 | 100 | 92 | 87 | 75 | 62 | 53 | 39 | 33 | 27 | ||||

32 | 100 | 95 | 86 | 78 | 68 | 52 | 43 | 36 | |||||

38 | 100 | 96 | 88 | 82 | 64 | 55 | 50 | ||||||

51 | 100 | 96 | 90 | 84 | 75 | 64 | |||||||

63 | 100 | 99 | 95 | 86 | 76 | ||||||||

75 | 100 | 100 | 97 | 88 | |||||||||

100 | 100 | 100 |

Gradation Curves

Note: The gradation shown are depend on the feed gradation, the crushing chamber, the material density, the material mud

content, its moisture and its crushability.