Sanitary tig welding stainless steel tubing

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

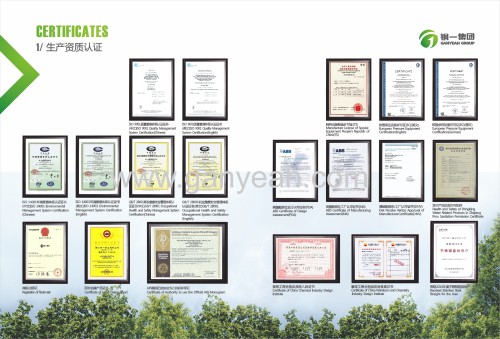

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

GRADE OF MATERIAL

1.Sanitary tig welding stainless steel tubing CHEMICAL COMPOSITION

ASTM/ASME | JIS | En | DIN | C | Cr | Ni | Mo | N | Others |

TP304 | SUS304 | 1.4301 | 0.080 | 8.0~20.0 | 8.0~11.0 | Max:0.1 | |||

TP304L | SUS304L | 1.4307 | X2CrNi18-9 | 0.035 | 18.0~20.0 | 10.0~12.0 | Max:0.11 | ||

TP316 | SUS316 | 1.4401 | 0.080 | 16.0~18.0 | 8.0~11.0 | 2.00~3.00 | |||

TP316L | SUS316L | 1.4404 | X2CrNiMo17 | 0.035 | 16.0~18.0 | 10.0~15.0 | 2.00~3.00 | 0.15~0.35 | |

TP321 | SUS321 | 1.4541 | X6CrNiTi18-10 | 0.080 | 17.0~19.0 | 9.00~12.0 | Max:0.11 | Ti: 5*(C+N)~0.70 |

2.Sanitary tig welding stainless steel tubing MECHANICAL PROPERTY

UNS | Tensile Strength | Yield Strength | Elongation in 2INCH. | Hardness Max, |

1.4301 | 500~700 | 195 | 35 | 90HRB |

1.4307 | 460~680 | 180 | 35 | 90HRB |

1.4401 | 510~710 | 205 | 30 | 90HRB |

1.4404 | 490~690 | 190 | 30 | 90HRB |

1.4436 | 510~710 | 205 | 30 | 90HRB |

1.4541 | 500~730 | 200 | 30 | 90HRB |

Sanitary tig welding stainless steel tubing APPLIED STANDARD

ASTM A249/ASME SA249 Welded austenitic steel boiler, superheater, heat-exchanger, and condenser tubes |

DIMENSION RANGE

TEST &INSPECTION PLAN

1.100% PMI / SPECTRO CHEMICAL ANALYSIS TESTS |

OPTION TEST&INSPECTION ITEMS

1.CRYSTALLING PHASE ANALYSIS |

THE DOCUMENTS

a.MTC (MATERIAL TEST CERTIFICATION) ACCORDING TO EN10204/3.1 OR EN 10204/3.2 |