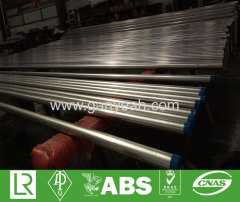

18.8 Stainless Steel Sanitary Tubing

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

18.8 Stainless Steel Sanitary Tubing

Stainless Steel – The broad classification of iron-base alloys (50% minimum iron) containing at least 10% chromium that are known for their excellent corrosion and heat resistance. Other elements are also added to form alloys for special purposes, in addition to the corrosion resistance imparted by the chromium. Some of these elements are: nickel for increased corrosion resistance, ductility and workability; molybdenum for increased corrosion resistance, particularly resistance to pitting, increased creep strength and high temperature strength; columbium and titanium for stabilization; sulfur and selenium for improved machinability.

Stress-Corrosion Cracking – Catastrophic failure by generally transgranular cracking occurring in stainless steels and other metals. It is caused by combined action of a corrosive environment and stress, often without outward appearance of general corrosion attack.

Tensile Strength – A short form of "ultimate tensile strength". The maximum tensile stress which a material is capable of sustaining. Tensile strength is calculated from the maximum load during the tension test carried to rupture and the original cross section area of the specimen.

Tensile Testing – A procedure used to determine the load at which a material will begin to plastically deform (the tensile yield strength) and ultimately at which it will break (the ultimate tensile strength). Resulting test values are a ratio of applied load (pounds) to cross-sectional area of the test sample (square inches) and are expressed in units of pounds per square inch (psi) or in metric units of megaPascals (MPa).

TIG (Tungsten Inert Gas) – A welding process that uses a non-consumable tungsten electrode to provide an electric arc to melt a work piece. Inert gases are used to shield the arc and the weld puddle to prevent oxidation during cooling. Used for heat exchanger, condenser and 18.8 Stainless Steel Sanitary Tubing.

18.8 Stainless Steel Sanitary Tubing Dimensions – O.D.- outside diameter. I.D.- inside diameter.

Wall thickness or gauge.

All tube dimensions are specific; pipe dimensions are nominal.Specific -actual measurements in inches.

Nominal - theoretical or stated value of a dimension.

Ultimate Tensile Strength – The stress in pounds per square inch (psi) that causes the material to fracture.

Weld Decay Test- A corrosion test developed for the black liquor industries (pulp/paper, sugar refining) to detect susceptibility of stainless steel weldments to attack by boiling hydrochloric acid cleaning solutions. Test results are reported as a ratio of the change in thickness of the weld to the change in thickness of the base material. A ratio of 1.0:1 indicates no difference between weld and base metal. A ratio of 1.25:1 indicates that the weld thickness changed by 25% more than the base material did.

Yield Strength – The calculated stress value at which a tensile test specimen experiences a plastic change in length with an increase in applied load. The yield strength of a material must be exceeded to achieve a permanent change in shape (i.e. forming or bending). Applied loads of less than the yield strength result in spring back, or the tendency for a material to return to its original shape when the load is removed.

.jpg)