Inox Tig Welding Steel Tubing

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

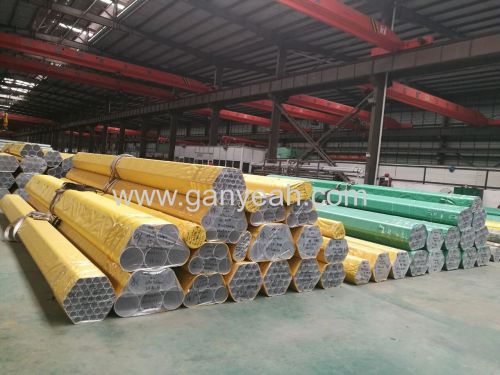

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

Ganyeah Group Inox Tig Welding Steel Tubing has been assessed for approval of its production facility for Inox Tig Welding Steel Tubing (Tubes). A quality control system established and operated by the company was audited by TUV Rheinland, and found the company has the facilities and capabilities to fabricate the cold finished (Cold-drawing and Rolling) Stainless Steel Welded Pipes (Tubes) complied with the requirement of the applicable ASME/ASTM material standard of ASME Boiler and Pressure Vessel Code Section II Part A

High Pressure boiler tubes are those tubes, which have the capacity of handling with high pressure and temperature. We are having a comprehensive range of high pressure boiler tube. Our production unit is using premier quality of raw material in the production of high pressure boiler tubes.

Condenser are normally chosen for steam heating systems, particularly on water and CIP applications with variable temperature conditions or when inlet water or CIP temperature is low, causing thermal shock conditions. The design features a floating tube sheet arrangement to reduce tube stresses. Standard material for tube-side construction is stainless steel, making these units ideal for acid or alkali wash systems.

High Pressure Inox Tig Welding Steel Tubing, selected prime raw material,cold drawn, cleaning and smooth surface on OD/ID,Withstand high pressure,no deformation after cold bending, no crack and break after flattening and flaring etc.

Widely used in the following fields:

High Pressure Boiler, Heater and condenser ,Boiler tubing , Condenser tubing

Delivery Condition:

Bright annealed (BA) or Pickel Annealed (PA)

Main Testing Terms and Procedure:

1. Heat Treatment and Solution Annealing / Bright Annealing

2. Cutting to required length and deburring;

3. Chemical Composition Analysis Test With 100% PMI and One tube from each heat by Direct Reading Spectrometer

4. Visual Test and Endoscope Test for Surface Quality Test

5. 100% Hydrostatic Test and 100% Eddy Current Test

6. Ultrasonic Test subject to the MPS (Material Purchase Specification)

7. Mechanical Tests includes Tension Test, Flattening Test, Flaring Test, Hardness Test

8. Impact Test subject to Standard request

9. Grain Size Test and Intergranular Corrosion Test

10. Ultrasoic measuring of Wall Thickness

Marking according to MPS and Standard

Stainless Steel Tubes Ends with Caps according to PO

In Seaworthy Wooden Cases With Plastic Paper protect

In Plywood Cases With Plastic Paper Protect(Recommend, All Plywood Cases made by ourselves with lower cost.)

Steel Racks Package

Hexagonal packing in Bundles

- Quality Control

Third Part Inspection Accepted according to EN 10204 3.2

ISO 9001 - 2008 issued by Lloyd's,

PED 97/23/EC By Lloyd's,

ASME Boiler and Pressure Vessel Code Certificated Certificate Issued by TUV

Marking & Packing