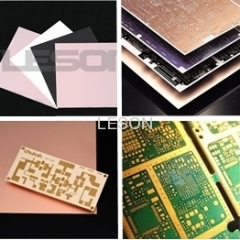

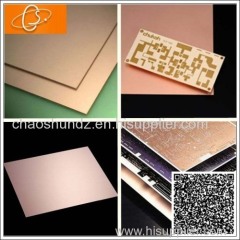

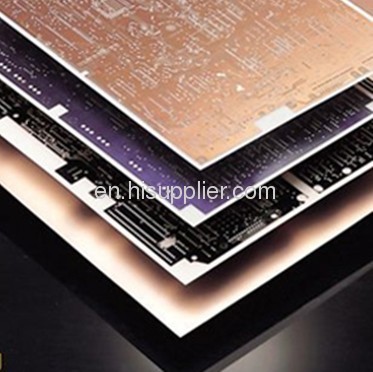

FR4 copper clad laminate sheet

| Min. Order: | 250 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500000 per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Copper Clad Laminate, GPO-3, G11, G10, FR4 Material |

Product Detail

| Model No.: | LS |

|---|---|

| Means of Transport: | Ocean |

| Place of Origin: | Zhejiang China (Mainland) |

| Brand Name: | LESON |

| Model Number: | FR4 |

| NEMA standard: | EPGC202 |

| Material: | epoxy fiberglass with copper foil |

| Spot goods size(width and length): | 1040X1240mm(41"X49") |

| Thickness: | 0.5mm to 3.2mm |

| Thickness of copper foil: | 18 micron,35 micron single side&double |

| Color: | Natural(Aqua green),yellow,black |

| Production Capacity: | 500000 per month |

| Packing: | 250 sheets per pallet,wooden pallet |

| Delivery Date: | 10-18 days,according to the quantity of the order |

Product Description

LESON FR4 Copper Clad Laminate is a kind of copper foil covered laminated board formed through heat pressing after the electric industry alkali-free glass fiber dips into thermoset epoxy resins and is covered with copper foil at one side or both sides. Usually used in PCB with printed circuit on one or both sides of computers, home electric appliances and other lines.

FR4 Copper Clad Laminate | |

1.Material | composite polymer(flame- retardant epoxy resin, E-glass fiber cloth with copper as cladding |

2.Technics | Mixing ,Coating,Folding,Laminated,Return Line,Cutting,Packing |

3.Color | natural color(light green ),yellow, and black,or as per customer's requirement |

4.Measurement | 41"X49",43"X49"(1040*1240mm) |

5. Feature: | Lead Free, Flame retardant, thermal reliability, lower warpage, |

6.Using scope | Suitable for high-count layer PCB, computer, communication equipment, OA equipment, lead-free PCB process, etc. |

7.Packing | carton packaging/ 250 sheet per pallet |

8. Certification | ISO9001,ISO14001,CQC,UL |

9.Payment | T/T,L/C, Western Union ,USD |

10. Technological requirements | For your choices |

Properities

1.Tg≥170°C(DSC)

2.UV blocking and AOI compatible ,so as to increase productivity efficiency

3.High thermal performance ,Td ≥325°C,T288≥5min,suitable for lead-free process.

4.Good flatness, smooth surface,no pits

Application

Suitable for high-count layer PCB, computer, communication equipment, OA equipment,

lead-free PCB process etc

Technician Data

| Item | Test condition | Unit | SPEC | Typical Value | |

Tg | DSC | °C | ≥170 | 175.2 | |

Peel strength(1OZ) | 288°C,10S | N/mm | ≥1.05 | 1.41 | |

Thermal Stress | 288°C,10S/solder dip | ____ | No delamination | 180S/ No delamination | |

Flammability | N/mm2 | LW | ≥415 | 580 | |

CW | ≥345 | 482 | |||

Surface Resistivity | After moisture | MΩ | ≥1. 0×104 | 2,52×107 | |

Volume Resistivity | After moisture | MΩ.cm | ≥1.0×105 | 3.21×108 | |

Dielectric Constant | 1MHz C-24/23/50 | ____ | ≤5.4 | 4.7 | |

Loss Tangent | 1MHz C-24/23/50 | ____ | ≤0.035 | 0.016 | |

Arc Resistivity | D-48/50+D-0.5/23 | S | ≥60 | 122 | |

Dielectric Breakdown | D-48/50+D-0.5/23 | KV | ≥40 | 58 | |

Moisture Absorption | D-24/23 | % | ≤0.5 | 0.1 | |

Td | Weight loss 5% | °C | 340 | 347 | |

CTE Z—axis | Alpha 1 | TMA | ppm/°C | ≤60 | 45 |

Alpha 2 | ppm/°C | ≤300 | 270 | ||

50-260°C | % | ≤3.0 | 2.9 | ||

T288 | TMA | min | ≥15 | 30 | |

CTI | IEC60112 Method | V | 175~250(Grade 3) | 200 | |

Suggestion for use

Please baking the laminate at 150°C,2 hours before using.

Please pay attention to the machining for the interbedded energy is lower than the normal FR-4.Rilling parameters are mainly dependent on hole size ,layer thickness, layer number ,copper thickness and stack height.

The following drilling parameters are for reference only .Typical drilling parameters for 0.4 ~1.0mm drills are as follows:

speed :45 ~105 KRPM

Feed rate:50~150 IPM

Retract rate:;500~1000 IPM

Suggest hit count:1500 HITS

Stack height:≤2pnls(2~6 layers), 1pnls(≤8 layers)

Entry Material:0.2mm Aluminum