Plastic extruder filter-hydraulic screen changer

1.0~15000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 50 pieces per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHB |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | DEAO |

| Auxiliary equipments for plastic extrusion plants: | for plastic extruder |

| Function: | filtration of the plastic melt |

| Application: | almost all polymers PP/PE//ABS/XPS/WPC |

| material: | high quality alloy steel |

| different type: | match with different type of extrusion plants |

| Production Capacity: | 50 pieces per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

Plastic extruder filter-hydraulic screen changer

When extruding plastic , a cleaning plastic melt is desired, but ,usually, the raw maerial we use is not virgin material, but reclaimed material, since the impurities in the plastic melt affects the quality of the product and impedes the operating process. It is esstential to ensure a perfect filtration process and improve the quality of the plastic melt by using a melt filter-Plastic extruder filter-hydraulic screen changer.

A perfect filtration performance without any deterioration of the melt quality is possible with the well-proven DEAO screen cangers, a large of which is incorporated into plastic extrusion machines.

When extruding plastic , a cleaning plastic melt is desired, but ,usually, the raw maerial we use is not virgin material, but reclaimed material, since the impurities in the plastic melt affects the quality of the product and impedes the operating process. It is esstential to ensure a perfect filtration process and improve the quality of the plastic melt by using a melt filter-Plastic extruder filter-hydraulic screen changer.

A perfect filtration performance without any deterioration of the melt quality is possible with the well-proven DEAO screen cangers, a large of which is incorporated into plastic extrusion machines.

Features of this Plastic extruder filter-hydraulic screen changer

1, this kind of DHB series of screen changer is the most widely used in all over the world, the price is very low, and operation is very simple.

2, this kind of screen changer can be applied for the multi-layer /co-extrusion line. and several screen changer can be controlled by one hydraulic unit, when the space is limited, this feature will be very important.

3, short screen changer time, a dirty screen to be replaced by a fresh one, only needs 2 seconds.

Advantages

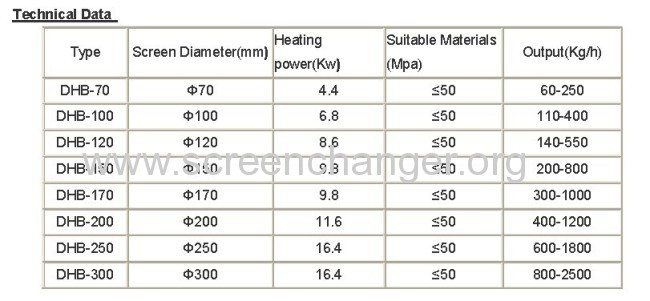

The Plastic extruder filter-hydraulic screen changer DHB appeal to a traditional but demanding audience. Designed for high production or recycling extrusion lines, due to ongoing technical development, have reached a high degree of ergonomics. The high reliability and durability testify to the quality of this product, which meets the diverse needs, with excellent results even in the most difficult and challenging situations. Available with filtering areas from Ø 70 to Ø 330 mm. units are equipped with a new protection system which allows better access to the sliding plate during screen replacement, and a new wiring system that allows rapid intervention in case of maintenance.

THE PLASTIC EXTRUDER FILTER- HYDRAULIC SCREEN CHANGER SUITABLE FOR THE PRODUCTION OF

Blown or Cast films

Flat sheet

Pipes and profiles

Cable coating

Recycling

Pelletizing from polymerization

Masterbatch and compound pelletizing

The Plastic extruder filter-hydraulic screen changer before delivery

THE PLASTIC EXTRUDER FILTER- HYDRAULIC SCREEN CHANGER SUITABLE FOR THE PRODUCTION OF