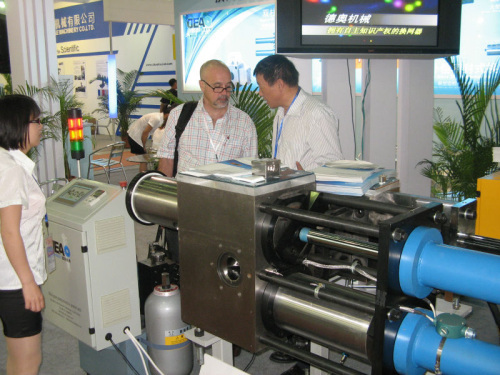

Two channel hydraulic screen changer for plastic extruder

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHZ |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Hydraulic Filter |

| Function: | Screening Filter |

| Brand Name: | DEAO |

| Function: | polymer melt filtration |

| Material: | high quality alloy steel |

| Application: | almost all kinds of polymer |

| Type: | different type to be matched with different type of extruders |

| Certification: | CE , ISO9001 |

| Production Capacity: | 50 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 20 days after receiving the down payment |

Product Description

Two channel hydraulic screen changer for plastic extruder

Description of two channel hydraulic screen changer for plastic extruder

This kind of two channel hydraulic screen changer now becomes more and more popular in nowadays, since all the manufacturer of plastic products take more care of the capacity of production and quality of the products. Due to the structure and features of this kind of screen changer, we do not need to stop the working machine when replce the dirty mesh , and also non-interrupt the production. so it can realize the continuous uninterrupted production.

Features of two channel hydraulic screen changer for plastic extruder

1), Two slide bars instead of the conventional flat plate

2), The slide bar is pushed and pulled by hydraulically, which is different from the hydraulic unit of the single plate hydraulic screen changer, does not have the accumulator.

3), Double-piston screen changer works simultaneously. One net works. Another replaced; without interrupting the flow of material and production. And eventually fulfills the exchange of screen without stopping the machine.

4), Exhaust system device can fully defuse the gas mixed in the materials, then improving product quality. And double channels expand the filtration area to meet more productive, more high-quality production need s from customers.

How to work

The screen change process

1), the breaker plates with screen on the working position.

2), one slide bar is pushed out .When screen change is required, the two slide bars will be pushed out by hydraulically one after another.

3), the dirty screen on the breaker plate is replaced to a fresh screen by manual operation,.

4), Air bleeding process,it is finished in a short time.

Technical Data

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 6 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 8 | 100--350 |

DHZ-2-155 | Screen wrapped on the piston(300*65) | 195 x 2 | 10 | 300-800 |

DHZ-2-230 | Screen wrapped on the piston(420*100) | 420 x 2 | 10 | 400-1200 |

DHZ-2-160 | Φ135 | 143 x 2 | 10 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 12 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 10 | 500-1500 |

DHZ-2-1800 | square screen be wrapped on the slide bar | 900x2 | 10 | 1000-2000 |

DHZ-2-2000 | Square screen be wrapped on the slide bar | 1000 x2 | 12 | 1000-3000 |

Applications

cast film (Bubble pack\ Medical\Food Wrap)

Sheet (Foam\Strapping\Plastic cardboard)

Coating (Hot melt adhesive)

Pipe (Corrugated\Gas Pipe) and profile

Compounding (Master Batch\filler)

Wire and cable extrusion

Tubing (Medical\ Industrial\Irrigation)

Fibers (Monofilament)

Blow molding

Pelletizing (strands and underwater)

Recycling of most polymers