Plastic extruder screen changer

1.0~40000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

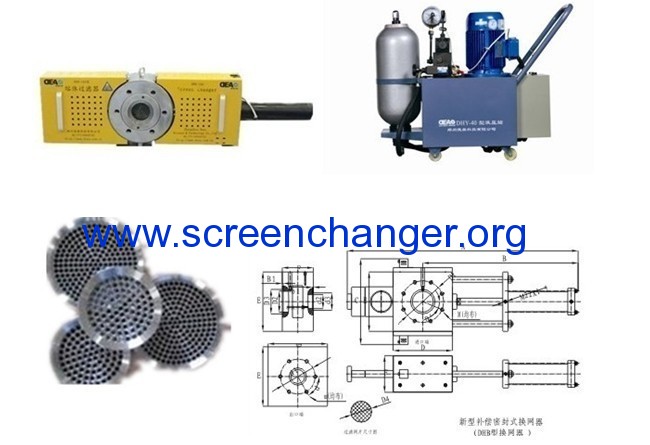

| Model No.: | DHB |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | DEAO |

| Product name: | screen changer/ melt filter |

| Attribute: | auxiliary equipment of plastic extrusion plant |

| Function: | polymer melt filtration |

| Application: | almost all polymers PP/PE//ABS/XPS/WPC |

| Material: | high quality alloy steel /38CrMoAl |

| Pressure resistant: | 500bar |

| Type: | different types to be match with extruders |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

There are impurities in most of the plastic materials, and if we want to improve the quality of our products, we need to filter the impurities out of the materials. This time, the plastic extruder screen changer seems to be very important. Because the impurities can be cleaned effectively by a screen changer, which is installed on the terminal of an extruder, between the terminal barrel and the die .

Plastic extruder screen changer

slide plate hydraulic screen changer DHB series

Generally speaking, this kind of slide plate screen changer is composed of several layers of screen. The support screen and the fine screen, the support screen is the coarse screen, and can prevent the larger particles from the entering the dense fine screen. The fine screen can prevent the small particles in the material.

The advantages of this series of plastic extruder screen changer

1, the screen change time is very short , the fresh screen replace the dirty one only need less than 2 seconds.

2, the operation is very simple

3, the price is low.

4,It is unnecessary to stop working extruder; at the same time it can dispense much labor

This kind of plastic extruder screen changer can be applied for the following extrusion lines:

The advantages of this series of plastic extruder screen changer

1, the screen change time is very short , the fresh screen replace the dirty one only need less than 2 seconds.

2, the operation is very simple

3, the price is low.

4,It is unnecessary to stop working extruder; at the same time it can dispense much labor

This kind of plastic extruder screen changer can be applied for the following extrusion lines:

Blown film and cast film (Bubble pack/ Medical/Food Wrap)

Sheet (Foam/Strapping/Plastic cardboard)

Coating (Hot melt adhesive)

Pipe ( Corrugated/Gas Pipe) and profile

Compounding (Master batch/filler)

Wire and cable extrusion

Tubing (Medical/Industrial/Irrigation)

Fibers ( Monofilament)

Blow molding

Pelletizing (strands and underwater)

Recycling of most polymers

PVC Profile extrusion line

.PVC.PE.PP Wood-plastic profile extrusion line

.PVC wood door panel extruding production line

.Corrugated pipe production line

.co-extrusion single screw extruder

.granulation line

.PVC foamed plate production line

.PC.PMMA.PS.MS sheet production line

.PP.HIPS.PE.EVA.EVAOH single screw multi-layers composite sheet production line

PP.PE board production line

.PMMA transparent sheet production line

.PC.PP hollow profile board production line

.ABS single layer ,multi-layers composite sheet production line

.ABS.PP.PS anti-static co-extrusion sheet production line

.Wide floor sheet, water proof sheet production line

.PVC free foamed sheet, board, production line

.PVC.PE.PP Wood-plastic profile extrusion line

.PVC wood door panel extruding production line

.Corrugated pipe production line

.co-extrusion single screw extruder

.granulation line

.PVC foamed plate production line

.PC.PMMA.PS.MS sheet production line

.PP.HIPS.PE.EVA.EVAOH single screw multi-layers composite sheet production line

PP.PE board production line

.PMMA transparent sheet production line

.PC.PP hollow profile board production line

.ABS single layer ,multi-layers composite sheet production line

.ABS.PP.PS anti-static co-extrusion sheet production line

.Wide floor sheet, water proof sheet production line

.PVC free foamed sheet, board, production line