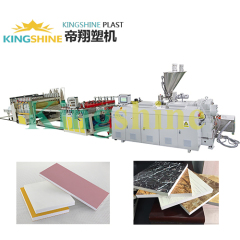

WPC foam building board production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Window Sill Extrusion Line | Window Sill Extruder, Water Pipe Extrusion Line| PP-R Pipe Production Line, Door Board Production Line| PVC Board Extrusion Line |

Product Detail

| Model No.: | SJSZ80/156, SJSZ92/188 |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | Keshengda |

| Packing: | as your customers' requiremnet |

| Delivery Date: | about 45 days |

Product Description

WPC foam building board production line

Wood plastic foam building templates extrusion line features:

Extrusion forming has short cycle, high efficiency, simple and practical process, the replacement of mold can produce various models and specifications of wood products. Therefore the extrusion forming is considered as the most ideal method in the WPC processing.

Optimized screw with small shear is not easy to cut the wood fibers to make uniform staying time in the machine. Wood flour and vegetable fiber is added up to 50-75%. The recycling plastic foam building templates, WPC construction board, wood profiles and other products have been vigorously promoted in the United States, Germany, Japan and other developed countries and regions recently, which are mainly used in wood plastic housing project with steel structure. Wood-plastic composite materials have environmentally friendly, saving energy, easy construction and good security.

Wood plastic building board has no maintenance and recyclable, low production costs, high surface hardness, abrasion resistance, easy to clean, anti-aging, light weight, long life, etc. Therefore they are widely used in high-rise building and bridge construction; turnover rate, high turnover frequency (up to 50 times or more).