Bonded Injection Molding NdFeB Magnet

0.2~20.0 USD

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Metric Ton/Metric Tons per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | magnet injection moulding |

|---|---|

| Means of Transport: | Ocean |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Application: | Industrial Magnet |

| shape: | bar,ball ,strip,stick,coil,block,sheet |

| Grade: | N35-N52,(M,H,SH,UH,EH) |

| Platings: | Ni,Zn,Au,CU |

| Place of Origin:: | Zhejiang, China (Mainland) |

| Brand Name:: | Joy |

| Export Area:: | All of the World |

| Production Capacity: | 100 Metric Ton/Metric Tons per Month |

| Packing: | According to customer's requirement |

| Delivery Date: | 15-20 days |

Product Description

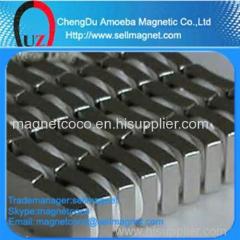

Bonded Injection Molding NdFeB Magnet

1) Material: Sintered Neodymium-Iron-Boron;

2) Temperature: The max operation temp is up to 200 degree centigrade or 380 curie temperature;

3) Grade: N33-N52, 33M-48M, 33H-48H, 30SH-45SH, 30UH-38UH and 30EH-35EH;

4) Shape: Ring, block, disc, bar and so on;

5) Size: According to customers' request;

6) Coating: Ni, Zn, gold, copper, epoxy and so on;

7) Application: Sensors, motors, rotors, wind turbines, wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on;

1) Material: Sintered Neodymium-Iron-Boron;

2) Temperature: The max operation temp is up to 200 degree centigrade or 380 curie temperature;

3) Grade: N33-N52, 33M-48M, 33H-48H, 30SH-45SH, 30UH-38UH and 30EH-35EH;

4) Shape: Ring, block, disc, bar and so on;

5) Size: According to customers' request;

6) Coating: Ni, Zn, gold, copper, epoxy and so on;

7) Application: Sensors, motors, rotors, wind turbines, wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on;

Magnets:

Magnet N-( N35, N38, N40, N42, N45, N48, N50),

Magnet M-(35M, 38M, 40M, 42M, 45M, 48M),

Magnet H-(35H, 38H, 40H, 42H, 45H),

Magnet SH-(30SH, 33SH, 35SH, 38SH, 40SH, 42SH),

Magnet UH-( 28UH, 30UH, 33UH, 35UH, 38UH),

Magnet EH-(28EH, 30EH, 30EH, 33EH, 35EH)

Magnet N-( N35, N38, N40, N42, N45, N48, N50),

Magnet M-(35M, 38M, 40M, 42M, 45M, 48M),

Magnet H-(35H, 38H, 40H, 42H, 45H),

Magnet SH-(30SH, 33SH, 35SH, 38SH, 40SH, 42SH),

Magnet UH-( 28UH, 30UH, 33UH, 35UH, 38UH),

Magnet EH-(28EH, 30EH, 30EH, 33EH, 35EH)

2. Customized Coating & Sizes Available

Surface treatment: Ni, Zn, epoxy, silver, gold, tin, Ni+Cu+Ni and Cr3+Zn;

Sizes limit: from 2mm to 140mm.

The most important point is that we can customize the size and shape according to your requests.

Bonded Injection Molding NdFeB Magnet

Bonded Injection Molding NdFeB Magnet

Neodymium (NdFeB)

NdFeB, the third generation of rare-earth permanent magnet, has high remanence, high coercive force, high-energy product and high performance/cost ratio.

Neodymium Magnets are easily formed into various sizes and widely used in many fields such as magnets for aviation, electronics, instruments, meters, machine and medical instruments. Neodymium metal is used extensively to produce Nd-Fe-B magnets, which have energy densities as high as 27 to 35 million gauss oersteds.

They are the most compact magnets commercially available. It is especially suitable for the development of magnets for high-performance, compact and light products.

.jpg)