ring bonded NDFEB magnet

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 100000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | N35/N40/N50 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Industrial Magnet |

| Shape: | Others |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | HONY |

| Type:: | Permanent,Permanent Magnet |

| Application:: | Industrial Magnet,sensors/motors/rotors/fi |

| Composite:: | Neodymium Magnet |

| product:: | Ring Bonded NdFeB Magnet for Micro M |

| Model Number:: | BRMA002 |

| Shape:: | ring/block/bar/earth/arc and so on |

| keyword:: | Ring Bonded NdFeB Magnet for Micro M |

| Production Capacity: | 100000pcs/month |

| Packing: | carton |

| Delivery Date: | 25 days |

Product Description

ring sintered NDFEB magnets: injection & molded

We produce Cylinder NdFeB magnets/Cylinder Sintered NdFeB Magnets

The Cylinder NdFeB Magnets/Cylinder Neodymium Magnet we are supplying are with following t specifications:

1. Sintered NdFeB Magnets with different grades of: N35,N38,N40,N42,N45,N48,N50,N52(M,H,SH,UH,EH,AH) etc.

2. Working temperature for Sintered NdFeB Magnets: from 80 degree centigrade to 230 degree centigrade.

3. Can be magnetized according to the requirements of clients.( thickness, width, length...)

4. Coatings: Ni, Zn, epoxy, gold, silver, Cu and so on(as per the requirements).

5. NdFeB Magnetic Material has super strong magnetic force and high intrinsic coercive force.

6. With precise tolerance.

Application for cylinder NdFeB Magnets/Cylinder Neodymium Magnet:

Magnetic separator, Sensors, Wind generators, Vibration motors, DC motors, Servo motors, Linear motors, VCM, MRI, Loudspeakers, Linear actuators, drives, toys, bags, household appliances, microphone parts, transmission equipments...

Features of cylinder NdFeB Magnets/Cylinder Neodymium Magnet:

Neodymium magnets are mainly made from neodymium ,iron, and boron. It is the ideal magnetic material in the world till now and have been used universally in the world . It has super strong magnetic force and high intrinsic coercive force and after concocting , it can stand very high working temperature, as high as 200 centigrade.

All These special features of NdFeB material make it irreplaceable in the world.

So till now, it has universally been used in electronics, aviation, motors, automobiles, medical apparatus, transmission machine... and even in many details of our everyday life.

Packaging & Delivery

| Packaging Detail: | Paper box & wooden box |

| Delivery Detail: | 10-60 days |

Specifications

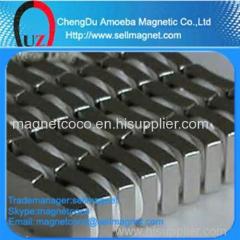

name : ring bonded ndfeb magnet for micro motor

Feature: permanent magnet/strong coercive force/precision dimension

Name of product: Ring Bonded NdFeB Magnet for Micro Motor

Material : NdFeB (Neodymium-Iron-Boron)

Test : ISO9001 ; TS16949; ROHS

Artwork : Bonded

Shape : ring,block,disc,bar,arc, rare earth and so on;

Size : as your drawing( be customized )

Coating : Epoxy Resin

Application : sensors,motors, rotors, wind turbines,wind generators,loudspeakers,magnetic holder, filters automobiles and so on.

Characteristic

Main products of our company By Powder Metallurgy :

1)Customized Metal parts as your design

2) Magnet------Bonded NdFeB; Sintered NdFeB; Ferrite(hard and soft ); AlNiCo etc.

We are supplier of NDFEB BLOCK MAGNETS,or call Neodymium block magnet, block sintered NdFeB Magnet, which can be used as fan generator magnets .

1.NdFeB magnet is The strongest power magnets in all of the permanent magnets. Which can be made in different shape, such as Block sintered NdFeB magnet, Disc sintered NdFeB magnet, etc.

2.Material:Sintered Neodymium-Iron-Boron;

3. The material Grade including: N35 to N52;N35M to N50M;N35H to N48H;N35SH to N45SH;N30UH to N40UH,N30EH to N38EH.Also we can suggest the grade according to where the magnets will be used according to our customer's request.

4. Advanced techniques: Utilizes new Sintered NdFeB magnet techniques and equipment such as strip casting, HDDR technology in our factory to allow us to make high performance NdFeB over N52 possible.

5. The Excellent strength value: the highest (BH)max reaches up to 51MGOe.

6. The Extremely Resistance to demagnetization with Hci,the intrinsic coercive force is over 30000Oe.Neodymium magnet loss -0.09~-0.13% on Br/°C;

7. The moderate temperature stability, their working stability is under 80 degree centigrade for low Hci for NdFeB magnet and above 200 degree centigrade for high Hci NdFeB magnet.

8.Various shapes and sizes or according to customers' requirement; Also we can design the size for our customer's request.

9.Effective Surface treatment to prevent corrosion, such Nickel coating(Ni-Cu-Ni coating);Zinc coating, gold coating, silver coating, tin(Sn) coating, epoxy coating, chemical coating, parylene coating, and so on;

10.Widely used in different application, such as sensors, Motor,rotors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on;

11.The quality control: we have our large and expert quality control department and we ensure the magnets ( block sintered NdFeB Magnet,block Neodymium Magnet) from our factory are in high quality.

12.We will provide our customers the test report and BH curves for each item magnets, and also we can do the PCT test ,salt spray test report, aging test report and provide the test report and so on according to our customer's request.

| Magnetic Characteristics And Physical Properties of Sintered Nd-Fe-B | ||||||

| Remanence | Coerciv Force | Intrinsic Coercive | Max Enery Product | Maximum working | |

| Grade | Br mb(KG) | hcb Koe(KA/m) | iHC Koe(KA/m) | (BH) max | temperature | |

| KJ/m2(MGOe) | Tw°C | |||||

| N35 | 1170-1210 | ≥10.8 (≥860) | ≥12 (≥955) | 263-287(33-36) | 80 | |

| N38 | 1210-1250 | ≥10.8 (≥860) | ≥12 (≥955) | 287-310(36-39) | 80 | |

| N40 | 1250-1280 | ≥11.6 (≥923) | ≥12 (≥955) | 302-326(38-41) | 80 | |

| N42 | 1280-1320 | ≥11.6 (≥923) | ≥12 (≥955) | 318-342(40-43) | 80 | |

| N45 | 1320-1380 | ≥11.0 (≥876) | ≥12 (≥955) | 342-366(43-46) | 80 | |

| N48 | 1380-1420 | ≥10.5 (≥835) | ≥12 (≥955) | 366-390(46-49) | 80 | |

| N50 | 1380-1450 | ≥10.5 (≥835) | ≥11 (≥955) | 374-406(47-51) | 80 | |

| N52 | 1430-1480 | ≥10.8 (≥860) | ≥11 (≥876) | 398-422(50-53) | 80 | |

| 35M | 1170-1210 | ≥10.8 (≥860) | ≥14 (≥1114) | 263-287(33-36) | 100 | |

| 38M | 1210-1250 | ≥11.0 (≥876) | ≥14 (≥1114) | 287-310(36-39) | 100 | |

| 40M | 1250-1280 | ≥11.4 (≥907) | ≥14 (≥1114) | 302-326(38-41) | 100 | |

| 42M | 1280-1320 | ≥11.6 (≥923) | ≥14 (≥1114) | 318-342(40-43) | 100 | |

| 45M | 1320-1380 | ≥11.8 (≥939) | ≥14 (≥1114) | 342-366(43-46) | 100 | |

| 48M | 1360-1400 | ≥11.8 (≥939) | ≥14 (≥1114) | 366-390(46-49) | 100 | |

| 50M | 1400-1450 | ≥13.0 (≥1033) | ≥14 (≥1114) | 382-406(48-51) | 100 | |

| 33H | 1130-1170 | ≥10.6 (≥844) | ≥17 (≥1353) | 247-263(31-33) | 120 | |

| 35H | 1170-1210 | ≥11.0 (≥876) | ≥17 (≥1353) | 263-287(33-36) | 120 | |

| 38H | 1210-1250 | ≥11.2 (≥890) | ≥17 (≥1353) | 287-310(36-39) | 120 | |

| 40H | 1250-1280 | ≥11.5 (≥915) | ≥17 (≥1353) | 302-326(38-41) | 120 | |

| 42H | 1280-1320 | ≥12.0 (≥955) | ≥17 (≥1353) | 318-342(40-43) | 120 | |

| 45H | 1320-1380 | ≥12.0 (≥955) | ≥17 (≥1353) | 335-366(42-46) | 120 | |

| 46H | 1330-1380 | ≥12.2 (≥972) | ≥16 (≥1274) | 350-374(44-47) | 120 | |

| 48H | 1360-1430 | ≥12.5 (≥995) | ≥16 (≥1274) | 366-390(46-49) | 120 | |

| 33SH | 1130-1170 | ≥10.6 (≥844) | ≥20 (≥1672) | 247-263(31-33) | 150 | |

| 35SH | 1170-1210 | ≥11.0 (≥876) | ≥20 (≥1672) | 263-287(33-36) | 150 | |

| 38SH | 1210-1250 | ≥11.4 (≥907) | ≥20 (≥1672) | 287-310(36-39) | 150 | |

| 40SH | 1250-1280 | ≥11.8 (≥939) | ≥20 (≥1672) | 302-326(38-41) | 150 | |

| 42SH | 1280-1320 | ≥11.8 (≥939) | ≥20 (≥1672) | 320-342(40-43) | 150 | |

| 45SH | 1320-1380 | ≥12.6 (≥1003) | ≥20 (≥1592) | 342-366(43-46) | 150 | |

| 33UH | 1130-1170 | ≥10.7 (≥852) | ≥25 (≥1990) | 247-263(31-33) | 180 | |

| 35UH | 1170-1210 | ≥10.7 (≥852) | ≥25 (≥1990) | 263-287(33-36) | 180 | |

| 38UH | 1210-1250 | ≥11.4 (≥907) | ≥25 (≥1990) | 287-310(36-39) | 180 | |

| 40UH | 1250-1280 | ≥11.4 (≥907) | ≥25 (≥1990) | 302-326(38-41) | 180 | |

| 30EH | 1080-1130 | ≥9.5 (≥756) | ≥30 (≥2388) | 223-247(28-31) | 200 | |

| 33EH | 1130-1170 | ≥10.2 (≥812) | ≥30 (≥2388) | 247-263(31-33) | 200 | |

| 35EH | 1170-1210 | ≥10.2 (≥812) | ≥30 (≥2388) | 263-287(33-36) | 200 | |

| 38EH | 1210-1250 | ≥11.4 (≥907) | ≥30 (≥2388) | 287-310(36-39) | 200 | |

| 30AH | 1080-1130 | ≥10.2 (≥812) | ≥35 (≥2785) | 223-255(28-32) | 220 | |

| 33AH | 1120-1170 | ≥10.2 (≥812) | ≥35 (≥2785) | 247-271(31-34) | 220 | |