Extruded Composite Duct

3.0~10.0 USD

| Min. Order: | 1000 Square Meter |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | Electronic Thermostat, Air Conditioning Module Machine, XPS Composite Duct, Water Source Heat Pump Unit, Plate Heat Exchangers |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Head Code: | Square |

| Shape: | Equal |

| Brand Name: | Tongxing |

| Production Capacity: | 10000 |

| Packing: | paper packaging |

| Delivery Date: | 20 days |

Product Description

Flame retardant composite duct

Product description

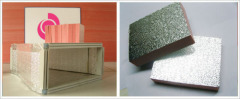

Extruded composite duct, also known as XPS composite duct, is a new innovation substitution for high-temperature duct of the air conditioners.Insulation board utilizes the advanced XPS extruded polystyrene as the core insulation material, with smooth surface, and complete closure internal structure, which has made essential improvement with outstanding performance in environment protection and continuously stable mass productions.

Extruded composite duct application:

Extruded duct insulation series products are applicable to all kinds of architectural industry, the air conditioning and ventilation installation; widely used in food processing, pharmaceutical products, machinery manufacturing, shopping centers, electronic industry, textile, sports entertainment, hotel, the supermarket, office buildings, government agencies, small villas, aviation manufacturing, etc. (the duct is not suitable for acid or alkaline occasions)

Product features:

1 light weight, easy installation, and effectively reduces the load bearing

2. Resistance to high pressure, non-absorbent and corrosion resistance,

3. Non-absorbent, moisture-proof, breathable

4. Long service life and low thermal conductivity of excellent performance

5. Noise absorption and vibration resistant

6. Clean and environmental protection, heat preservation and sound insulation.

Extruded composite duct product parameters:

1. Fire-proof level (GB8624-1997): Level B1 of inflaming retarding

2.Density: 45-60Kg/m3

3.Water absorptivity: Less than 1.5%

2.Density: 45-60Kg/m3

3.Water absorptivity: Less than 1.5%

4Heat guide coefficient: 0.027 w / M · K

5.compression strength: 250Kpa

6.Compressive intensity10%: 0.29Mpa

5.compression strength: 250Kpa

6.Compressive intensity10%: 0.29Mpa

7.Working temperature: -50 ℃~ 110℃

.jpg)

.jpg)

.jpg)