Polyurethane Composite Duct

5.0~15.0 USD

| Min. Order: | 1000 Bag/Bags |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000bags/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | Electronic Thermostat, Air Conditioning Module Machine, XPS Composite Duct, Water Source Heat Pump Unit, Plate Heat Exchangers |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | TONG XING |

| Production Capacity: | 10000bags/month |

| Packing: | paper packing |

| Delivery Date: | 20 days |

Product Description

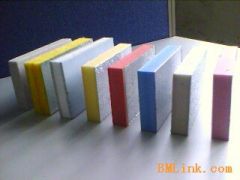

Polyurethane composite duct is a kind of panel composite with high flame-retarded PU (polyurethane) foam covering both sides with fireproof standard of Level-A. aluminum board. PU (polyurethane) is a subtle and closed-cell foam material with low thermal conductivity, which makes the polyurethane composite duct has excellent performance, flexible strength ,good energy-saving effect and a long term life almost 20 years usage.Tested by the national building material testing center, polyurethane composite duct meets the related firefighting regulations of the and the .Its application has been gradually extended to all types of air distribution system such as industrial, commercial and civil.

Product features:

1. Fire retardant: excellent and low thermal insulation thanks to the high density

2. Sound insulation and noise absorption--can absorb the noise from the shaking when ventilated.

3. Light weight, easy installation decrease the building load, especially suitable for the tall building structure.

4. Silent operation, vibration and reverberation are minimized, increasing system comfort.

5. Easy maintenance and modification can be performed on site, cut and gluing can be applied in any section of the ducts.

6. Environmental protection and Durability, not decay, mildew and no corrosive

7. PVC socket type connection technology and stable structure can save space and cost.

Product parameters:

Density | 50-70 kg/m3 |

Thermal conductivity | 0.021W/(m.k) |

.Compression Strength | 10%; 0.2MPa |

Velocity Of Air Flow (MAX. | 5% |

Operating Temperature | -100℃-180℃ |

Water absorption | 1%-3% (24 hours) |

.Oxygen Index | 53% |

Sheet thickness | 20mm-50mm |

.jpg)

.jpg)

.jpg)