High Power China Graphite Electrode Manufacturer

| Min. Order: | 20 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 8000 |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Graphite Products |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | BENHONG |

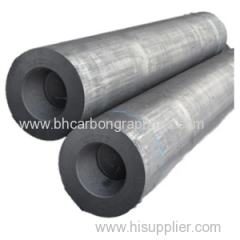

| Type: | Graphite Electrodes |

| Composition: | Graphite, Needle BCK , Petroleum BCK |

| Carbon Content: | High-Carbon |

| Forming Way: | Molded Graphite |

| Modulus of Rupture: | 10-14 MPa |

| Ash: | 0.3% |

| Length: | 1500-2700mm |

| keywords: | graphite electrode rp hp uhp |

| Nipple: | 3tpi 4tip 4tpil |

| Transport Package: | Wooden Pallets with Steel Strips |

| Production Capacity: | 8000 |

| Packing: | Graphite Electrodes are packed on wooden pallets |

| Delivery Date: | negotiate |

Product Description

High Power China Graphite Electrode Manufacturer

Product Description

Products Detail: eaf graphite electrodes

Graphite electrode refers to a kind of high-temperature resistant graphite conductive material, which is made of

petroleum bck and asphalt bck as aggregates and coal tar pitch as binder through raw material calcination,

crushing and grinding, batching, kneading, molding, baking, impregnation, graphitization and mechanical processing.

It is called artificial graphite electrode (graphite electrode for short), to distinguish it from natural graphite electrode

prepared with natural graphite as raw material.

Processing Program:

1) The graphite is immersed in oil. Before machining, the graphite material should be immersed in the engine

oil for tens of hours to make the oil penetrate into the graphite material, so that the ash powder will not fly

during machining and a smooth surface can be obtained.

2) Paint scribing. After the electrode is rough machined on the contour surface, a thin layer of white paint shall be sprayed on the scribing surface before scribing, so that the lines are clear and convenient for machining.

3) Perform machining. uhp graphite electrode for eaf

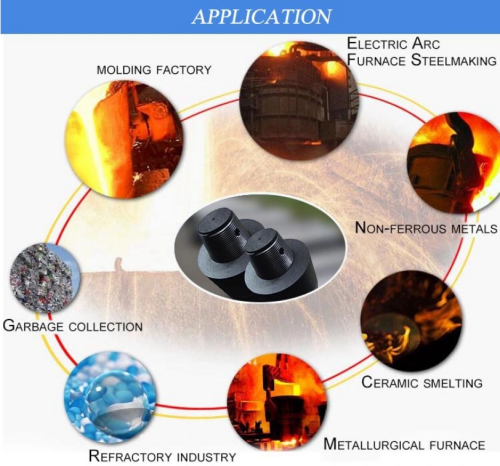

Application:

(1) For electric arc steelmaking furnace

(2) For submerged arc furnace

(3) For resistance furnace

(4) Used to prepare special-shaped graphite products

ITEM | PR | HP | UHP |

Electric Resistivity(μΩ·m) | ≤8.0 | ≤7.0 | ≤6.2 |

Bending Strength(MPa) | ≥10.0 | ≥10.5 | ≥10.5 |

Elestic modulus(GPa) | ≤12.0 | ≤12.0 | ≤14.0 |

Bulk Density(g/cm3) | ≥1.66 | ≥1.62 | ≥1.58 |

Coefficient of Thermal Expansion(X10-6/ºC) | ≤2.7 | ≤2.4 | ≤1.5 |

Ash(%) | ≤0.3 | ≤0.3 | ≤0.3 |

Form of processing:

There are mainly three types of graphite electrode machining: pressurized vibration method, CNC automatic forming method and

mechanical processing method. arc furnace graphite electrode

(1) Pressurized vibration method: the pressurized vibration method requires a special machine tool, and the shape of the electrode

master mold is opposite to that of the electrode. Graphite materials and forming tools are placed relatively during processing, leaving

a certain gap. The processing fluid composed of water and abrasive is injected into the machine. At the same time of passing through

the processing fluid, the graphite and the forming tool are subject to ultrasonic vibration. Under the action of abrasive impact force,

the graphite is stripped to the required shape. The abrasive is SiC, B4C or diamond. The rougher the abrasive is, the faster the

machining speed is. When the machine tool is working, it adopts sealed type and water curtain type for processing. It is suitable for

EDM for mass production.

(2) Numerical control automatic forming method: the numerical control automatic forming method requires a special graphite electrode

forming machine, which adopts the numerical control method, has an automatic tool exchange device, and can accommodate multiple

tools. In order to improve the processing environment, the graphite electrode is surrounded by a water curtain to prevent the graphite

dust from dispersing everywhere. In addition, the wet machining method can also be used to prevent tool wear and graphite dust

dispersion by using water-soluble cutting fluid. The machine tool has a high-performance filtering device, which can separate the

cutting fluid from the graphite chips, and can ensure continuous processing for a long time. It is an ideal special equipment for

graphite electrode processing, and is suitable for electrode processing for moulds. However, its price is relatively high and it is

not widely used in China.

(3) Machining method: the machining method is the main method adopted by domestic general mold manufacturers.

| Graphite Electrode | |||||||||||

| Project | Nominal diameter mm | ||||||||||

| 75~130 | 150~225 | 250~300 | 350~450 | 500~800 | |||||||

| Level | Excellent | - | Excellent | - | Excellent | - | Excellent | - | Excellent | - | |

| Resistivity μΩ·m ≤ | Electrode | 8.5 | 10 | 9 | 10.5 | 9 | 10.5 | 9 | 10.5 | 9 | 10.5 |

| Nipple | 8 | 8 | 8 | 8 | 8 | ||||||

| Flexural strength MPa ≥ | Electrode | 10 | 10 | 8 | 7 | 6.5 | |||||

| Nipple | 15 | 15 | 15 | 15 | 15 | ||||||

| Elastic Modulus GPa ≤ | Electrode | 9.3 | 9.3 | 9.3 | 9.3 | 9.3 | |||||

| Nipple | 14 | 14 | 14 | 14 | 14 | ||||||

| Bulk density g/cm3 ≥ | Electrode | 1.58 | 1.53 | 1.53 | 1.53 | 1.52 | |||||

| Nipple | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | ||||||

Thermal expansion coefficient 10-6/ºC Room temperature ~600ºC ≥ | Electrode | 2.9 | 2.9 | 2.9 | 2.9 | 2.9 | |||||

| Nipple | 2.7 | 2.7 | 2.8 | 2.8 | 2.8 | ||||||

| Ash content % ≤ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | ||||||

Company Profile:

FAQ:

Q: Are you a trading compnay or manufacture?

A: We're factory.

Q:How long is your delivery time?

A: Generally it will need about 15-20 days if the goods are not in stock.

Q:Do you provide samples?

A: Yes, we could provide the stock free sample, buyer only pay the freight cost.

Q:What is the main customers?

A:The main customers are from all over the world.