China Graphite Electrode Manufacturer Graphite Electrode

| Min. Order: | 20 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 5000 |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | UHP |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | BENHONG |

| Type: | Graphite Electrodes |

| Composition: | SiC |

| Carbon Content: | High-Carbon |

| Grade: | UHP |

| Forming Way: | Molded Graphite |

| Crystal Morphology: | Graphite Electrode |

| Production Capacity: | 5000 |

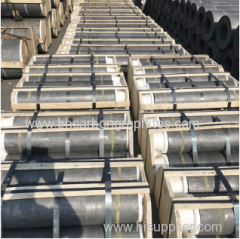

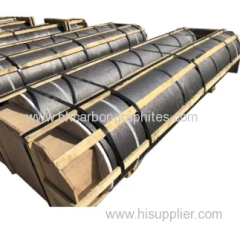

| Packing: | Graphite Electrodes are packed on wooden pallets |

| Delivery Date: | negotiate |

Product Description

Essential details

Place of Origin:

Hebei, China

Brand Name:

benhong

Model Number:

RP, HD,HP,SHP,UHP

Type:

Electrode Block

Application:

Steel Making, electric arc furnace (EAF) steel production

Length:

1600~3000mm

Grade:

UHP (Ultra High Power)

Resistance (μΩ.m):

4 - 9 Micro

Apparent Density (g/cm³ ):

1.58 - 1.76 G/cc

Thermal Expansion:

1.5 - 2.8 X10-6

Flexural Strength (N/㎡):

9.5-11.0 Mpa

Product name:

electrode graphite

Color:

Black

Size:

Customized Size

Raw material:

graphite electrode

Density:

≥1.52

Feature:

Good electrical conductivity

Sample:

Avaliable

Keyword:

Graphite electrode

Advantage:

Good stable thermal shock

Supply Ability

Supply Ability100 Ton/Tons per Day electrode graphite

Packaging & delivery

Packaging DetailsStandard export packaging or according to customer's requirementsPortShanghai,Qingdao,ect

Graphite Electrode

Graphite electrodes are characterized by low resistance, good electrical conductivity and thermal conductivity, high resistance to oxidation and thermal shock, high mechanical strength, etc. According to its high quality and low quality, it can be divided into ordinary power graphite electrode, high power graphite electrode and ultra high power graphite electrode.

Advantages1.Anti-oxidation treatment for longevity. 2.High-purity,high-density,strong chemical stability. 3.High machining accuracy,good surface finishing. 4.High mechanical strength,low electrical resistance. 5.Resistant to cracking & spalling. 6.High resistance to oxidation and thermal shock.

Applications1.For arc furnaces of electric arc furnaces. Graphite electrodes are most often used in a coal-smelting electric furnace.

2.For a closed arc

3.For a resistor furnace

4.For the production of graphite shaped products. The graphite electrode blank is also used for processing in various crucibles,shapes, boats and heating elements and other graphite products. For example, in the quartz glass industry, for each production of 1 ton of an electric melting tube, a graphite electrode 10 m is required, for each quartz brick of 1 ton it is necessary to consume 100 kg of graphite electrode.SpecificationElectrode Nipple:Graphite electrodes and nipples have the advantages of high strength, not easy to break, and good current passing.

Name | Unit | Nominal Diameter | ||||||

UHP Ultra-High-Power | HP Superstrong | RP Conventional Power | ||||||

≤Φ400 | ≥Φ450 | ≤Φ400 | ≥Φ450 | ≤Φ300 | ≥Φ350 | |||

Resistivity | Electrode | ΜΩ · m | ≤5.5 | ≤6.5 | ≤8.5 | |||

Nipple | ≤4.5 | ≤5.5 | ≤6.5 | |||||

Flexural Strength | Electrode | MPa | ≥11.0 | ≥10.5 | ≥9.8 | ≥8.5 | ≥7.0 | |

Nipple | ≥20.0 | ≥16.0 | ≥15.0 | |||||

Elastic Modulus | Electrode | GPa | ≤14.0 | ≤12.0 | ≤9.3 | |||

Nipple | ≤18.0 | ≤16.0 | ≤14.0 | |||||

Density | Electrode | g / cm3 | ≥1.66 | ≥1.67 | ≥1.62 | 1.6 | ≥1.53 | ≥1.52 |

Nipple | ≥1.75 | ≥1.73 | ≥1.69 | |||||

Coefficient Of Thermal Expansion | Electrode | 10-6 / ℃ | ≤1.5 | ≤2.4 | ≤2.9 | |||

Nipple | ≤1.4 | ≤2.2 | ≤2.8 | |||||

ASH | % | ≤0.3 | ≤0.3 | ≤0.5 | ||||

.jpg)

.jpg)