PP Hollow Construstion Board Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 80sets/Year |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | KS120-75 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PP/PE |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75KW |

| Capacity: | 400 |

| Best service: | Siemens electric system |

| Best quality: | ABB inverter |

| Turnkey Project: | Siemens PLC system |

| Highest PLC Tech: | Best T die |

| Mechanical line speed: | 1.2m/min |

| Width: | 915mm |

| Thickness: | 8-18mm |

| Plate layers: | One or three |

| Color: | Customer Choice |

| After-sale service: | Guaranteed for one year |

| Production Capacity: | 80sets/Year |

| Packing: | film or wood |

| Delivery Date: | 45days |

Product Description

Company Introduction

Jiangsu Kingshine Plastic Machinery Co., Ltd. is one of the most professional plastic machinery manufacturing enterprises in China.

Kingshine pay attention to technological innovation, actively introduce advanced foreign technology, and constantly develop new products.

-Over 20 years' experience in manufacutre machines.

-Over 40 countries' customers in the world.

-Over 3000 machines are using.

-Over 50 lines send to the world per year.

Kingshine Machinery is dedicated to various solutions in Plastic Machine customized to customs satisfy.

Exhibition

Production Introduction

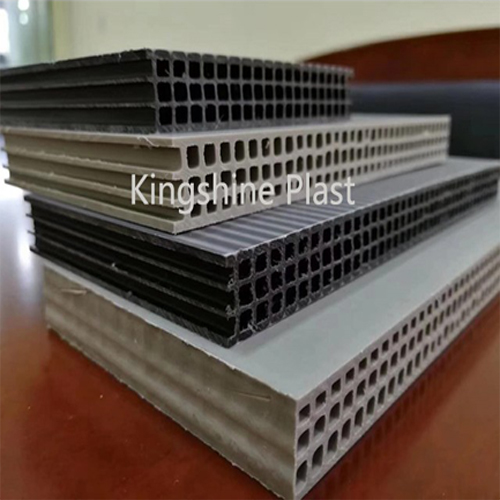

PP Hollow Construction Board Production Line

PP architectural template production line production of PP plastic template products can fire prevention, moisture-proof, non-toxic

environmental protection, low cost, simple construction, the characteristics of PVC plastic building template production line machinery

and equipment production of plastic building template product surface level off, smooth, have to nail, saw, sticky, easy processing, can

be repeated use, easy to recycle, etc.

The construction formwork produced by plastic formwork equipment has been used for a long time in many large construction companies

in China, and the effect is better than the traditional wood formwork and bamboo plywood.

Structure features

The production line consists of forming, compounding, stress elimination, trimming, and cutting parts, each part is equipped with an inverter

for stepless speed adjustment, the whole production line can be adjusted synchronously. The production line possesses other features, such

as easy for operation and maintenance, convenient for buying wearing parts, reliable product quality, and etc.

Product Features

1.Good water resistance.

2.High construction efficiency and good quality.

3.Long life and repeated use.

4.Good thermal insulation.

5.Low cost.

Application

1. Construction of sunroof in buildings, halls, shopping centers, stadiums, public places of

2. Entertainment and public facilities

3. Rain shield of bus stations, garages, pergolas, corridors.

4. Transparent shields for security forces in nursery schools, airports, factories.

5. Skylight of modern agriculture and aquacultures, indoor pools

6. Sign board for ads, light box and exhibition service

7. Ceilings partition walls and exhibition stands partition in office and residence

Perfect Service

Pre-sale service

-To provide information and market research.

-To provide consultation,to provide many kinds of conveniences and market service,etc.

-To help customers make the project planning and system requirements analysis.

-Take our products maximum to meet clients' requirements.

-To play the greatest overall economic benefits of customers' investment.

After-sale service

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements.

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Perfect Package

Packaging Details

Standard shipping package for PVC WPC Foam Board making machine

Port

Shanghai

Lead Time

Quantity(Sets) | 1 - 1 | >1 |

Est. Time(day) | 45 | To be negotiated |

Technology support

-To provide installation and test for the machine.

-To provide formulas and technology of relevant products.

-To provide information of chemical material manufactories.

-To provide technical training for clients' employees.