PP Hollow Construction Board Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 80sets/Year |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | KS120-75 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PP/PE |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75KW |

| Capacity: | 400 |

| Best service: | Siemens electric system |

| Best quality: | ABB inverter |

| Turnkey Project: | Siemens PLC system |

| Highest PLC Tech: | Best T die |

| Mechanical line speed: | 1.2m/min |

| Width: | 915mm |

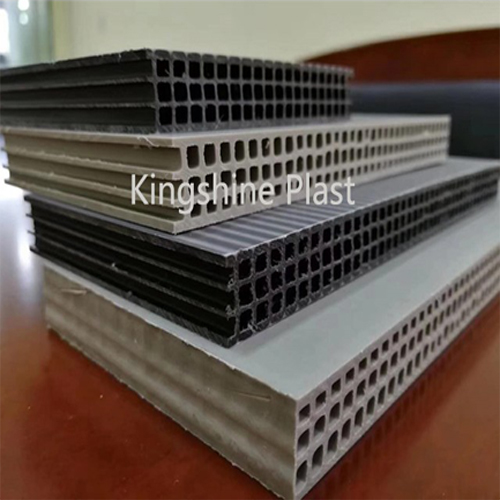

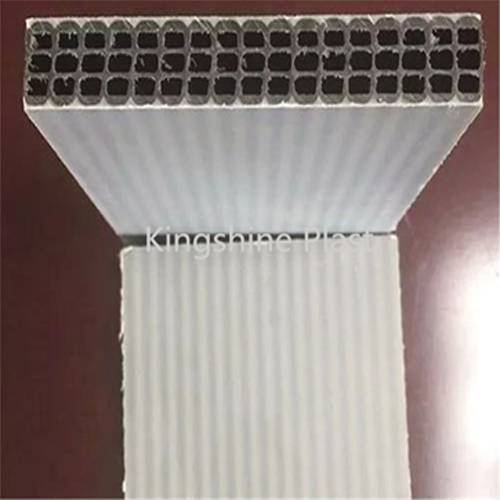

| Thickness: | 8-18mm |

| Plate layers: | One or three |

| Color: | Customer Choice |

| After-sale service: | Guaranteed for one year |

| Production Capacity: | 80sets/Year |

| Packing: | film or wood |

| Delivery Date: | 45days |

Product Description

PP Hollow Construction Template Production Equipment

PP plastic building template production line equipment production of plastic building template,

can add straw, corn cob, wheat pole, sawdust and other powder, mixed in PP raw materials through

special process to produce a variety of new construction template for construction site needs.

This machine consists of two single screw extruder, hydraulic net changer, mould,

setting machine, primary tractor,annealing furnace, cooling box, secondary tractor,

cross cutting machine and conveyor.

PP architectural template production line production of PP plastic template products can fire

prevention, moisture-proof, non-toxic environmental protection, low cost, simple construction, the characteristics

of PVC plastic building template production line machinery and equipment production of plastic building template

product surface level off, smooth, have to nail, saw, sticky, easy processing, can be repeated use, easy to recycle, etc.

The construction formwork produced by plastic formwork equipment has been used for a long time in many large

construction companies in China, and the effect is better than the traditional wood formwork and bamboo plywood.

Product Features

1. Good water resistance.Even if it is completely immersed in water for many days, it will not be deformed by dampness.It will not rot and rust.

2. It is not friendly to cement and is sticky. It is easy to remove the mold after construction and will not be deformed due to cement adhesion.

3. High construction efficiency and good quality.The surface of the building constructed with it is smooth and smooth, without secondary modification.

4. The working procedure is saved and the construction efficiency is improved.At the same time, the surface of the template can be pretreated

to get the desired metope pattern.

5. Light weight, convenient construction and high efficiency.

6. High support strength, not easy to deform.

7. Low cost.

8. Long life and repeated use.The final damaged plastic template can still be smashed again and reprocessed into a new template, saving resources

and meeting the requirements of "Green industry "Requirements.

9. Good thermal insulation, which is conducive to shorten the construction period.

10. Wood can be added for various treatment, but also for welding, so the construction site can be flexible for secondary processing.

Factory Environment

Application

Service

Pre-sale service

-To provide information and market research.

-To provide consultation,to provide many kinds of conveniences and market service,etc.

-To help customers make the project planning and system requirements analysis.

-Take our products maximum to meet clients' requirements.

-To play the greatest overall economic benefits of customers' investment.

After-sale service

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements.

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support

-To provide installation and test for the machine.

-To provide formulas and technology of relevant products.

-To provide information of chemical material manufactories.

-To provide technical training for clients' employees.

Packing

Packaging Details

Standard shipping package for PVC WPC Foam Board making machine

Port

Shanghai

Lead Time

Quantity(Sets) | 1 - 1 | >1 |

Est. Time(day) | 45 | To be negotiated |