WPC PVC Foam Board Making Machine Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 80/156 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75KW |

| Capacity: | 300-500KG/Hr |

| Best service: | Schneider electric system |

| Best quality: | ABB inverter |

| Turnkey Project: | Siemens PLC system |

| Highest PLC Tech: | Best T die |

| Contactor: | Schneider |

| Mechanical line speed: | 0.6-6m/min |

| Screw: | conical twin screw |

| Thickness: | 3-25mm |

| Daily Capacity: | 8-10Tons |

| Color: | Customer Choice |

| Production Capacity: | 20sets/month |

| Packing: | film or wood |

| Delivery Date: | 45days |

Product Description

WPC PVC Foam Board Making Machine Line

1. This production line consists of special twin screw extruder, mould, vertical installed 3-roller calendar, and

auxiliary machines, our company will offer formulation and full sets of technology of the complete processes.

The production line has the advantages of large output, stable extrusion, and high foamed ratio.

2. The barrel and screws of extruder are specially designed for PVC and WPC foamed products extrusion,

venting type design, the barrel and screws are bimetallic treatment, effectively reduce the big wearing problem

caused by PVC and WPC materials, highly increases the service life of extruder.

3. Adopting PLC people-machine interface computer control,Siemens LCD. The operation parameters can be

customized and showed on the display.

4. Material of mould is high quality alloy steel 5CrNiMo forging treatment, the surface of inner flow channel is

under chrome plating treatment and polish treatment. The structure of mould adopts imported technology, the

die cavity under hard chrome plating treatment and mirror type polishing treatment.

5. The board thickness is easily regulated; mould lips are changeable, so when produce boards of different

thickness only to regulate the bolts on mould lips is ok.

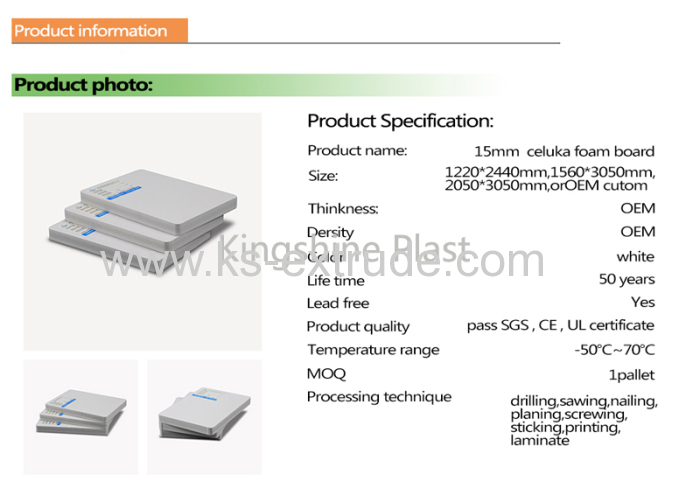

Our Product

Our 2019 Best! wpc machine is high technical and easy to operated. Also CE approved. This

wpc production line can be used to produce various WPC products, such as wpc foam board, wpc floor,

wpc door, ect. WPC products is made from PE/PP/PVC+wood powder+additives. It is a new generation

of environment protective material and very popular in the world at present. WPC product have both wood

and plastic double properties, and it's mechanical performance is better than wood.It also have the features

of water-proof ,fire-resistant,anti-corrosion,anti-moth,100% recycled.

Product Features

1. steady capacity and energy conservation.

2. ISO and CE certificate can be supplied.

3.Using international advanced CAD design software.

4.High plastify capacity of screw and barrel.

5. Large extrusion quantity and highefficiency.

Application

Our 2019Best! wpc machine is highly advaned. The wpc product have a wide application. such as

plank wpc floor,pavilion, chair, wpc door,buliding template,tray ,rail crosstie etc. wpc machine Board

thickness from 3mm to 40mm which has a wide range of application: furniture board(wardorbe/kitchen

cabinet/bathroom cabinet/PVC doors)construction template/advertising board...

Machine Data

Model | LD800 |

Max. width of product(mm) | 1220 |

Extruder model | SJZ80/156 |

Max. extrusion capacity(kg/h) | 400 |

Extruder power(kw) | 75 |

Cooling water(M3/h) | 13 |

Compressed air(M3/min) | 0.6 |

Our Company

-Over 20 years' experience in manufacutre machines.

-Over 40 countries' customers in the world.

-Over 3000 machines are using.

-Over 50 lines send to the world per year.

Kingshine Machinery is dedicated to various solutions in Plastic Machine customized to customs satisfy.

Our service

1.Our company will provide relevant information on various technology and business consulted

by customers.Ifclients want to visit our company, we will offer all they need for convenience.

2.After signing contract, company designs groundsill installation chart for water, electricity and

gas of equipmentbasing on real condition and customers'requirement and provides detail order

list and matching manufacture forreference for customer.

3.After equipment arrival, our service personnel will arrive at posted locale for installaion, debugging,

training andtechnology transfer till customers can operate independently and manufactures eligible

products.

Service personnelhave to arrive at customer'S locale in time when we provide service for client again.

Packing & Delivery

List

NO. | Item | Quantity |

1 | Feeder | 1 set |

2 | Conical Twin-screw Extruder | 1 set |

3 | Mould | 1 set |

4 | Calibration Table | 1 set |

5 | Haul-off | 1 set |

6 | Cutter | 1 set |

7 | Stacker | 1 set |

Standard shipping package for PVC WPC Foam Board making machine.

Port

Shanghai

Lead Time

Quantity(Sets) | 1 - 1 | >1 |

Est. Time(day) | 45 | To be negotiated |

Technology support

-To provide installation and test for the machine.

-To provide formulas and technology of relevant products.

-To provide information of chemical material manufactories.

-To provide technical training for clients' employees.