WPC PVC Foam Board Extruder Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 92/188 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75KW |

| Capacity: | 400KG/Hr |

| Best service: | Siemens electric system |

| Best quality: | ABB inverter |

| Turnkey Project: | Siemens PLC system |

| Highest PLC Tech: | Best T die |

| Contactor: | Schneider |

| Screw: | conical twin screw |

| Daily Capacity: | 8-10Tons |

| Thickness: | 3-25mm |

| Mechanical line speed: | 0.6-6m/min |

| Color: | Customer Choice |

| Production Capacity: | 20sets/month |

| Packing: | film or wood |

| Delivery Date: | 45days |

Product Description

WPC PVC Foam Board Extruder Machine

This machine adopts latest coating and laminating technology, and is to

laminate the functional or decorative films with the board together.The whole

machine is in synchronous way.

Machine Details

PVC furniture board is pvc crust foam board or Celuka foam board. Smooth, light weight , high density, high hardness ,

moisture-proof and waterproof , mildew proof and anti-corrosion , non-toxic and no benzene , green products , not easy

to deformation resistance to compression. PVC furniture board (Chevron board or Andy board PVC high, hardness white

crust foaming board ) household decoration: bathroom cabinet board, furniture board, household decoration board, all kinds

of household of the shelf.

Our PVC foam board machine include the special Twin-screw extruder, mould and other auxiliary machines . We supply

you the best material formulation and all of technology. It is with big output, stable extrusion, high foaming, good and wear-

resisting surface and so on.PVC crust foam board has such characteristics as sound separation, sound absorption, heat

separation, temperature-keeping,etc.

Product Details

Extruding product characteristics:

1). Waterproof, anti-flaming, dampproof, rotproof, mothproof, light weight, keep temperature, sound and heat insulation and shockproof etc;

2). Color-way is not changed long time and not easy to aging under radiation resistance;

3). This product can be manufactured by general wood processing tools. It can be drilled, sawed, nailed and dig. It is the best substitute to raw wood, aluminum and composite product;

4). It can be welded as every general welding stipulation and also can be stick to other PVC materials.

5). It has smooth surface and is easy to print.

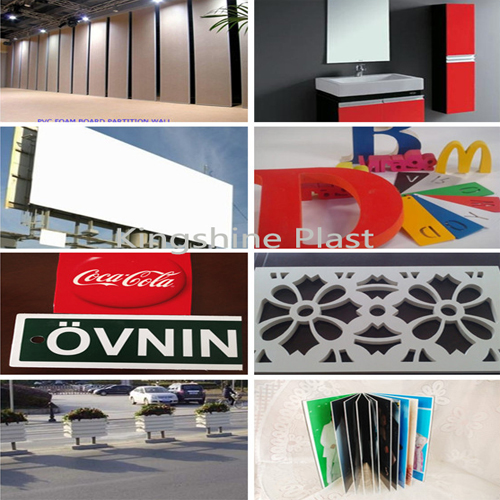

Application

Architecture decoration industry: building template board, outdoors plate, indoors decoration plate,

residential house, office, separation of public building, commercial decoration frame, plate used in

dust-free room, celling plate.

Household decoration: bathroom cabinet board, kitchen cabinet, furniture board, home decoration board,

various household shelves.

Advertisement industry:Screen printing, computer engraving, advertising board, exhibition plate, logo plate.

Transport industry: ship, plane, bus, and train, floor covering, core layer, indoors decoration plate.

Industrial application: rot proof project in chemical industry, thermal shaped part, plate for refrigeration warehous,

special cool-keeping protection plate.

Other applications: construction mold plate, sports apparatus, aquaculture material, seashore wet-proof facility,

water-resistant material, arts material and all sorts of light separation plate.

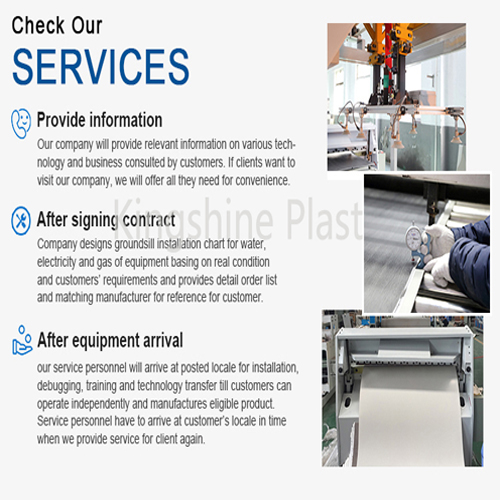

Our service

Pre-sale service

-To provide information and market research.

-To provide consultation,to provide many kinds of conveniences and market service,etc.

-To help customers make the project planning and system requirements analysis.

-Take our products maximum to meet clients' requirements.

-To play the greatest overall economic benefits of customers' investment.

After-sale service

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements.

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Packing & Delivery

Packaging & Delivery :

Packaging Details

Standard shipping package for PVC WPC Foam Board making machine

Port :

Shanghai

Lead Time :

Quantity(Sets) | 1 - 1 | >1 |

Est. Time(day) | 45 | To be negotiated |

Company Culture

Jiangsu Kingshine Plastic Machinery Co., Ltd. is one of the most professional plastic

machinery manufacturing enterprises in China.Kingshine pay attention to technological innovation,

actively introduce advanced foreign technology, and constantly develop new products.

Exhibition

-Over 20 years' experience in manufacutre machines.

-Over 40 countries' customers in the world.

-Over 3000 machines are using.

-Over 50 lines send to the world per year.

Kingshine Machinery is dedicated to various solutions in Plastic Machine customized to customs satisfy.