J23 Series Mechanical Power Press

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | J23-40 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Manual |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | durmapress |

| Normial Force: | 400KN |

| Slipper Stroke: | 100mm |

| Slipper stroke times: | 55min |

| Max.Closing Height: | 300mm |

| Connecting Rod adjuster: | 80mm |

| Throat Depth: | 240mm |

| Pole Distance: | 30mm |

| Angle of inclination: | 30degree |

| Motor Power: | 4Kw |

| Weight: | 3500Kg |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

Product Description

1.Cast frame ,to ensure high rigidity and less deformation

2.turn-key and rigid clucth,with flexible movement and reliable performance.

3.Crankshaft placed crosswise,six -side rectangle guides of the slide in high accuracy

4.Press-collape block device,to ensure safety in press operation.

5.Emergency brake device,to control the slide stop at any position within 135°.if any occurrence such as the arms ,any substance accessing in working area.photo electric protector ,air cushion and other optional accessories can be equipped with power press according to the user demands .

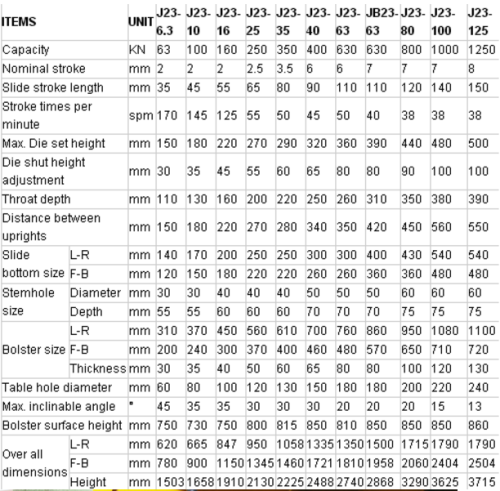

Data Parameter

Company Information

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Visit our Shanghai Exporting Center.

After-Sales Service

* Training how to instal and operate the machine.

* Installation service.

* Engineers available to service machinery overseas.

* Spare parts and warranty.

Certifications

CUSTOMER VISIT

Our Service

Quality and Service Assurance:

1.we have Q & C department in our factory and our engineer have much experience and can design the suitable machine for our clients.

2.our machine can produce the nice production, can guarantee good quality.the production is confirm to the national standard even the international standard

3.the products should not have scratch and the flatness

Technical R & D Department: design teams for different kind of production line.

Package:

1.As to the roll forming machine's package, it should be nude.

2.we'll protect the machine well before shipment, to prevent machines from rusting and damage.

Repairs:

Warranty: 1 year since the date of B / L on

Installation and Commissioning:. We will send professional engineers to buyers' country for installation and commissioning Buyer pays each engineer 100USD / Day besides the round-tickets, room and board.

OUR TEAM

DURMA SUCCESSFUL CASE

DURMA OFFICE

Packing & Delivery

RFQ

Payment Terms:

T/T, L/C at sight are acceptable by us.

Guarantee period:

Our product quality guarantee period is 13 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers' incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.