J23 Series mechanical hydraulic 100 ton power press

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, L/C, D/P, T/T, Money Gram |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

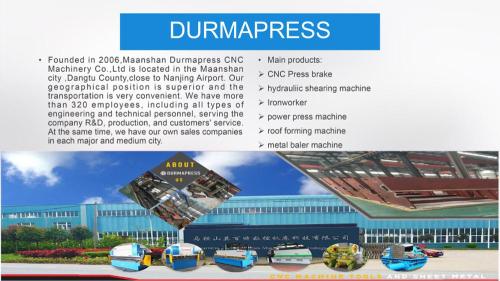

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | J23-100 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Others |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | durmapress |

| Product name: | J23 Series Power Press |

| motor brand: | siemens - germany |

| Nominal Force: | 800KN |

| Electrics: | Schneider- Germany |

| warranty: | 5 years |

| Keyword: | Automatic Punching Machine |

| Application: | Metal Sheet Stamping |

| Usage: | Pressing Metal Products |

| Material: | Q235 |

| Brand: | durmapress |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the machine |

| Delivery Date: | 30 days after deposit confirmed |

Product Description

Ma'anshan Durmapress Co., Ltd mainly produces "Tenroy" brand press brake, shearing machine, rolling machine, punch press, air duct making machine, press brake tools, punch press tools and shearing blades etc. Our products are sold throughout the country, exported to more than 80 countries.

Sophisticated equipment and specialized manufacturing, provide us a strong guarantee for the large-scale growth and quality assurance on high-tech products. Tenroy has a number of professional products installation and commissioning workshop and precision parts processing workshop, owing numerical control milling planer, large-scale numerical control boring lathe, numerical control horizontal type treating center etc.

Tenroy always regard "quality first, credibility first, customer first" as purpose, and "blaze new trails, people-oriented" as the spirit of our enterprise. We provide first-class service for customers and a platform for our staff members. We'd like to provide our full support to our new and old customers! So as to help the company that handle with sheet metal manufacturing production create efficiency, and reduce each product processing costs to the minimum.

CE certificate

Japan NOK seal

Top tool wedge compensation

Front support easy operated adjustbale

Servo motor, Ball screw

Customer satisfaction is our eternal pursue.

Application:

A. Pressing and withdrawing axle and sleeve

B. Bending and deep drawing sheet metal

C. Straightening, forming, cutting and punching various materials

D. Applied in compression trial.

E. External cover of computer and sheet metal parts

F. OA steel furniture drawer and rail parts

G.External cover of air conditioner ,and sth.liked.

200 ton power press for sale,power press machine JH21

Structure:

1. Casting machine fuselage with stable performances;

2. C-frame machine fuselage, open and tiltable with large working space easy for discharging the processed works and the waste materials;

3. Rigid clutch, simple structure;

4. Belt-type brake, easy for adjustment;

5. Collapsed-type safety fuse to protect the whole machine from being damaged due to overloading.

6. Horizontal crankshaft, easy for maintenance

200 ton power press for sale,power press machine JH21

Characteristics:

1.The machine fuselage with higher strength and rigidity, economic and durable;

2.Simple structure, good versatility, easy operation and maintenance.

200 ton power press for sale,power press machine JH21

Introduction of the power press machine:

ABSOLUTE ®JB23 punch press is a suitable open type crank press featuring a left and right open type machine body (i.e. C-shaped machine body). Its steel plate welded body has high shock-absorbing performance. Its novel overall design gives the machine elegant appearance. Its throat has certain depth. The compact structure makes the use convenient and operation safe. The punch press is equipped with a turn-key rigid clutch, a cam band brake and a press-down type safety device. Its working table is open on three sides, so the mold loading and unloading and operation are convenient. The punch press is widely used for it provides good conditions for mechanization and automation. And as main equipment for plate punching production, the punch press can be used for punching holes, blanking, trimming, bending, shallow stretching and forming in national defense, aerospace, automobile, tractor, motor, electrical appliance, bearing, instruments, agricultural machine and tool, bicycle, sewing, mechanical appliance, daily hardware and coinage departments.

| 1.Steel welded body, tempering treatment, accuracy and stability; |

| 2.Vertical located crankshaft, compact structure; |

| 3.The crankshaft undergoes grinding treatment after high frequency quenching; |

| 4.Lengthened rectangular guideway with a surface of bronze plate; |

| 5.Pneumatic dual balance cylinder, which balances the slide block and punch weight to reduce noise and impact; |

| 6.PLC control and imported safety dual valve; |

| 7.Wet clutch and hydraulic overload protector. |

| 1. The Machine use Rigid rotated bond clutch rigid and well supported. The clutch gives continuous strokes for mass production. |

| 2.Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy. |

| 3. Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running. |

| 4. Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine. |

| 5. Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA. |

| 1. The Table and RAM body cast iron structure, the whole body is tempered, use the secondary transmission, the transmission part of the crankshaft horizontal Placement, flywheel and gear are the external open style, easy maintenance. |

| 2. Slider is a cast box structure and rigid. Collapse of the slider-style installation of pressure overload protection device, simple structure,if the slider overload, the fuse collapse is damaged, then protect the machine tool and die from damage. |

| 3. Die height adjustment of slider with manual mode, using V shaped slider guide rail, easy adjustment. |

| Model and specification | J23-80 | J23-100 | J23-125 | J23-200 | J23-250 |

| Nominal pressure (kn) | 800 | 1000 | 1250 | 2000 | 2500 |

| Slipper stoke (mm) | 100 | 100 | 140 | 145 | 145 |

| Slipper stoke times(time/min) | 50 | 40 | 38 | 38 | 38 |

| Max closing height (mm) | 270 | 300 | 370 | 420 | 410 |

| Height adjustment(mm ) | 60 | 80 | 100 | 100 | 100 |

| Distance between slipper centre and machine(mm) | 260 | 310 | 395 | 400 | 400 |

| Worktable dimension(mm) | 470*750 | 570*860 | 740*1150 | 780*1250 | 780*1300 |

| Size of die handle bore (mm) | 60*80 | 60*80 | 60*85 | 60*85 | 60*85 |

| Worktable thickness(mm) | 80 | 80 | 110 | 120 | 130 |

| Slipper underside bore (mm) | 260*300 | 360*400 | 360*430 | 410*500 | 410*500 |

| Motor(kw) | 5.5 | 7.5 | 11 | 15 | 15 |

| Dimension(mm) | 1765*1265*2650 | 1940*1490*2850 | 2350*1780*3600 | 2540*2010*3800 | 2740*2280*3850 |

1.Standardization of Service "212" |

| 2: response in 2 hours |

| 1: provide solution in 1 day |

| 2: solve complaint in 2 days |

| 2.Installation Service |

| Installation Services are available with all ERMACO machines. We dispatch technician to customer's factory for installation and preoperation of machines. ( Customers only need to pay the airfare and hotel ) |

| 3.Training Service |

| Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines. |

| 4.Quality Guarantee |

| We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data. |

| We arrange final test before shipment. We run the machine for a few days, and then use customer's materials for test. After making sure machine is the best performance, then make shipments. |

| Machine warranty is 3 year. We offer flexible extended warranties if needed. |

FAQ:

1. Are you a factory or a trade company?

We are manufacturer with own factory for more than 25 years, export proportion 50%~60%.

2. How can I trust your company?

A. With professional design and sales team, we can serve you the perfect solution with lowest cost.

B. Assessed by third party, national patents for all equipment.

C. Welcome to inspect any time, we are near Shanghai airport.

D. About the machine, we are the first manufacturer of briquette machine, hydraulic balers, alligator shears, shredders are also our main products.

3. Is your price competitive?

Surely we will give you best factory price based on superior product and service.

competitive price scrap metal competitive price scrap metal hydraulic shearing machineing machine