.jpg)

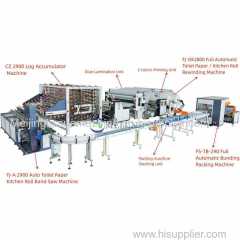

Toilet Paper Machine

| Payment Terms: | T/T |

|---|---|

| Supply Ability: | 1 |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ZYJ |

|---|---|

| Brand Name: | Jumping |

| Export Area: | all over the world |

| Production Capacity: | 1 |

| Delivery Date: | 60days after order |

Product Description

ZDJ-XJ(II) Toilet Roll Production Line is a new generation toilet roll converting machine, which integrates photoelectric and pneumatic controlling. It adopts PLC, Frequency speed controlling, and electric cabinet that using man-machine interface operating. It also has the features of easy operation and easy adjusting. Relevant positions equip with photoelectric switch to inspect machine running (e.g. paper breakages, non-core running or others). It has automatic stop function. Rewinder equips with automatic tension controlling for adjusting tension automatically. Independent motor controlling and automatic loading device lowers the labor cost and increases working efficiency. It is the first choice among toilet roll processing machines.

Main features:

(1) Pioneer rewinding technique within China, adopting photoelectric controlling to make the paper roll tightly first and then loosely and different elasticity in different parts, avoiding disengage between the tissue and the core after long time storage.

(2) Fully automatic core-replacing device. No human needed to replace the cores. Automatically push the finished product after rewinding, and process next rewinding.

(3) Automatically finish trimming, gluing and sealing at one time. Replace the traditional line trimming achieving the popular trimming and tail gluing technique abroad. Left 5mm-18mm ending of the product for convenience.

(4) Equipped with the embossing device that makes the tissue softer according to the customer's requirement. Lower the product weight and production cost.

(5) Photoelectric sensor tracks the machine running, insuring production quality during high-speed running.

(6) Adopting frequency speed controlling and PLC.

Process chart illustration:

(1) Automatically rewind into tissue rolls(trimming and tail gluing)

(2) Automatically convey to accumulator

(3) Load to automatic log saw according to the principle of "frist-in frist-out"

(4) Automatically slit into specified size

(5) Automatically convey and pack

Main features:

(1) Pioneer rewinding technique within China, adopting photoelectric controlling to make the paper roll tightly first and then loosely and different elasticity in different parts, avoiding disengage between the tissue and the core after long time storage.

(2) Fully automatic core-replacing device. No human needed to replace the cores. Automatically push the finished product after rewinding, and process next rewinding.

(3) Automatically finish trimming, gluing and sealing at one time. Replace the traditional line trimming achieving the popular trimming and tail gluing technique abroad. Left 5mm-18mm ending of the product for convenience.

(4) Equipped with the embossing device that makes the tissue softer according to the customer's requirement. Lower the product weight and production cost.

(5) Photoelectric sensor tracks the machine running, insuring production quality during high-speed running.

(6) Adopting frequency speed controlling and PLC.

Process chart illustration:

(1) Automatically rewind into tissue rolls(trimming and tail gluing)

(2) Automatically convey to accumulator

(3) Load to automatic log saw according to the principle of "frist-in frist-out"

(4) Automatically slit into specified size

(5) Automatically convey and pack