High Speed Toilet Paper Making Machine Production Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 30 sets/year |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Foshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | FJ-CD |

|---|---|

| Means of Transport: | Ocean, Land |

| Product Type: | Toilet Tissue |

| Processing Type: | Winding Machine |

| Certification: | CE |

| Brand Name: | MEIJING |

| Speed: | 0-250m/min |

| Warranty: | 2 years |

| Processing Type: | Paper Slitting and Rewinding Machine |

| Machine size: | 500*290*180mm |

| Raw material: | Parent roll/Virgin Pulp |

| Programmable controller: | Siemens PLC |

| Application: | To produce kitchen towel & toilet paper roll |

| Automatic Function:: | Embossing--Perforating--Tail gluing--Edge Trimming--Rewinding |

| Machinery Test Report: | Provided |

| Production Capacity: | 30 sets/year |

| Packing: | standard packing |

| Delivery Date: | 60-75 days |

Product Description

Foshan Manufacturer Rewinder Toilet Roll Manufacturing Machinery

Embossing Paper Tissue Making Machine

-------Product Description-------

How to produce paper tissue products?

Toilet paper, kitchen towel, industrial roll ,cotton soft roll, which machines shall be need and related material?

To produce toilet paper rolls, there are different production solution like following ~

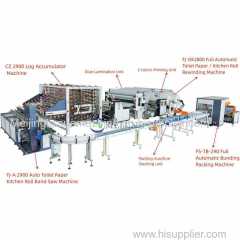

1. Full AutoToilet Paper/Kitchen Towel Rewinder

2. Auto Accumlator (optional machine)

3. Toilet Paper cutting machine

4. Toilet Paper Packing Machine

Machine Name | Full Auto Toilet Paper Making Machine | |||

Machine Model | 1760 | 2200 | 2600 | 2800 |

Parent Paper Width | 2000mm | 2200mm | 2600mm | 2800mm |

Parent Paper Dia | 1500mm | |||

Finished Products Dia | 90-300mm | |||

Finished paper core Dia | 30-55mm | |||

Back Stand | 1-4 ply | |||

Machine Speed | 220-250m/min | |||

Parameter Setting | Siemens Brand PLC computer operating system | |||

Perforation Distance | 90-200mm (4 knife)160-300mm ( 2 knife) | |||

Driving system | Each station driving by individual motor and individual frequency converters | |||

Machine Structure | Wallboard type | |||

Pneumatic System | 3 horse air compressor,a minimum pressure of 5kg/cm2Pa | |||

Machine Weight | 6-12 tons | |||

Certificates | CE, ISO9001:2008, SGS | |||

Equipped Device: | ||||

Embossing Unit | steel to rubber, individual control and driving | |||

Glue Lamination system | dot by dot lamination, Deco embossing Lamination, | |||

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. The Full Automatic Toilet Paper Machines production chart:

Unwinding - Embossing -Glue Lamination-Perforating-Rewinding-Automatic core loading - Tail-gluing - Edge trimming.

2. Automatically change the paper core, also can produce toilet paper roll without roll core.

3. Automatic Tail-trimming, gluing, gluing at the same time

4.This is a great machine to make customized to produce industrial roll, kitchen towel, maxi roll and cotton soft towel on one machine.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------

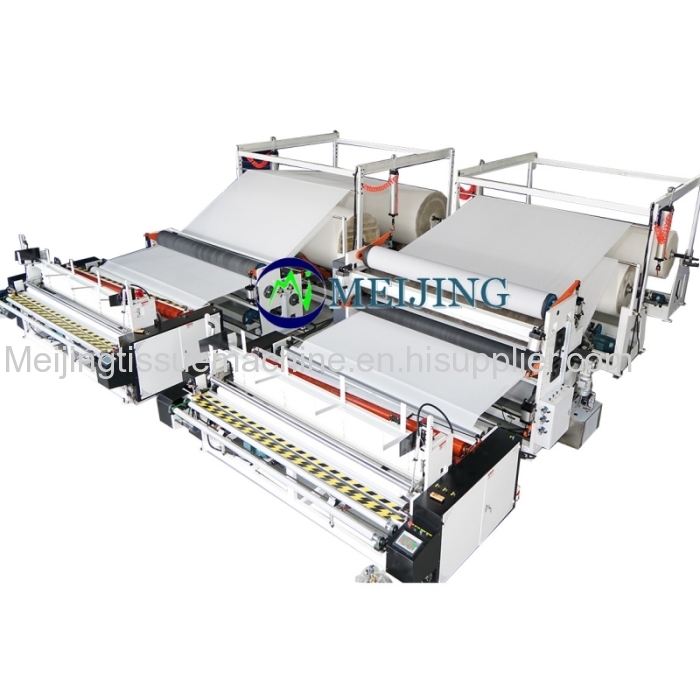

1. Full Auto Toilet Paper Making Machine

1.The Toilet Paper machine is used to produce small toilet paper roll/kitchen towel/Maxi Roll;

2. Finished Roll dia from 90-300mm;

3. Advanced Siemens PLC program control & Siemens Touching Screen

4 Individual motor drive & frequency inverter control;

5. Embossing pattern is customized (full embossing or edge embossing) ;

6. High speed: 220-250m/min;

7. The machine will stop when paper broken to avoid waste caused by no paper or paper broken;

8.Web tension can be set by touching screen.

Machine Name | Full Auto Toilet Paper Making Machine | |||

Machine Model | 1760 | 2200 | 2600 | 2800 |

Parent Paper Width | 2000mm | 2200mm | 2600mm | 2800mm |

Parent Paper Dia | 1500mm | |||

Finished Products Dia | 90-300mm | |||

Finished paper core Dia | 30-55mm | |||

Back Stand | 1-4 ply | |||

Machine Speed | 220-250m/min | |||

Parameter Setting | Siemens Brand PLC computer operating system | |||

Perforation Distance | 90-200mm (4 knife)160-300mm ( 2 knife) | |||

Driving system | Each station driving by individual motor and individual frequency converters | |||

Machine Structure | Wallboard type | |||

Pneumatic System | 3 horse air compressor,a minimum pressure of 5kg/cm2Pa | |||

Machine Weight | 6-12 tons | |||

Certificates | CE, ISO9001:2008, SGS | |||

Equipped Device: | ||||

Embossing Unit | steel to rubber, individual control and driving | |||

Glue Lamination system | dot by dot lamination, Deco embossing Lamination, | |||

2. Full Auto Log Saw Machine

1. Full servo motor driven rotary knife to cut,reduce the deviation of materials;

2. The cutting surface is nice and neat;

3. 610mm cutting blade;

4.Mitsubishi PLC program controller;

6. Auto grinding knife cutting high precision, safe and reliable;

7. Equipped with pneumatic brake function, can prolong the service life of motor and make braking perfect;

8.Suction Device can absorb the waste produced by sharpening and discharge it out of the machine;

9.Equipped with photoelectric checking system and large diameter of spiral cutter, it can auto set the length and cut precisely;

Machine Name | Full Auto Log Saw Machine | |||

Feeding length | 2850mm | |||

Max. Roll cutting size | 100-145mm; (other sizes can be ordered), one cutting mould for ± 5mm | |||

Horizontal cutting length | adjustable, Servo control. | |||

Out put line | 2 lines | |||

Machine Speed | 120 cuts/min * 2 rolls/cut | |||

Function model | Spiral rotating the round blade & Continued Paper Roll Marching | |||

Driving system | Servo motor driving | |||

Knife grinding | Pneumatic grinding wheel, time can be controlled on panel. | |||

Round blade outer dia | Φ610mm slitting blade (Germany brand) | |||

Grinding wheel | Carborundum grinding wheel | |||

Clamping tool | TWO sets of clamping tools | |||

Frequency converter | Mitsubishi Frequency converter | |||

PLC | Mitsubishi PLC | |||

Motors | Servo motor | |||

Install Power | 10kw, 380V 50HZ | |||

Certificates | CE, ISO9001:2008, SGS | |||

3. Full Automatic Toilet Paper Bundling Packing Machine

1.This machine will used to pack toilet paper or kitchen towel into plastic bag;

2. The machine can be connected with automatic paper cutting machine to realize the automatic process of product counting,

bag taking, bag filling, bag sealing and cutting;

3.The machine adopt 9 servo control, servo material sorting, servo push arm, servo pulling, servo forward, servo double lift, servo

bag opening, servo sealing, servo belt, servo bag taking;

4.Adopt high-end sensor, photoelectric switch detection, fault automatic display, easy to track and maintain;

5.The machine has servo control system can go to the origin point automatically (slowly back to the origin point).

Machine Name | Full Automatic Toilet Paper Packing Machine | |||

Capacity | 12-20bag/min | |||

Single roll size | 3 column : 90-140mm; 4 column : Ø 90-120mm | |||

Bag size/Rolls per bag | L300*W(180-480)*H(90-280) mm | |||

Bundling bag mode | pre-made bag with air-bleed hole Max bag length: 850mm | |||

Bundling bag material | PE, thickness::≥0.05mm | |||

Bundling bag store | 40mm, Two bag storage | |||

Bundling bag storing quantity | ≤300 pcs | |||

Feeding mode | Full automatic feeding system | |||

Suitable for packing | Horizontal paper tissue roll | |||

Heating Power | 1.4KW | |||

Inlet pipe diameter | 10-12mm | |||

Air supply | 0.6MPA(Supplied by user) | |||

PLC | Mitsubishi PLC | |||

Power supply | 380V 50HZ | |||

Machine size | L7500*W1850*H2200 mm | |||

Certificates | CE, ISO9001:2008, SGS | |||

--------------------------------------------------------------------------------------------------------------------------------------------------------------

The Optional Device

Full Embossing Unit

1.The whole wallboard Structure: 30 mm steel plate;

2.Steel roll to steel roll or steel roll to rubber roll;

3.Independent motor driving, frequency converter control;

4.Embossing roll dia: 320 mm depends on machine width;

5.We will provide embossing pattern for free or design.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

High Level Glue Lamination System

1. Two plies of paper web, each one goes to embossing first (steel roller to rubber roller);

2.The glue will be caught on the bulge of embossing face, goes to the middle of two steel rollers ( there point point combined two

plies into one, or nested combined two plies into one);

3. Make the paper web more absorbency and strong;

4.Lamination unit with glue capacity adjusting control, to control the glue capacity from the glue tank to the paper surface;

5. It adopts scraping glue system, also can adopt rolling glue, the cost is different, scraping glue on the glue is much more stable

than rolling glue on the glue, and the glue speed is more faster, and the probability of sticking paper is much lower;

6.Independent motor control glue: when stop machines, this motor automatically stir glue to avoid glue dry hard to clean;

7.When paper broken, machine will stop automatically.

--------------------------------------------------------------------------------------------------------------------------------------------------------

Finished Product

Why Choose Us

Foshan Meijing Machinery Manufacture Co., Ltd. established in 2005.We are well-known manufacture more 18 years experience, specializes

in machinery for paper tissue in China, a professional manufacturer and specialized in household paper tissue converting machines and ancillary

machinery.

We are dedicated to the creation of high-quality and advantage design machines that remain to meet different market products demands.

All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

If you are interested in any of our products or would like to discuss a customized order, please feel free to contact us. We are looking forward to

forming successful business relationships with new clients around the world in the near future.

Debugging equipment and technical personnel in the company under the guidance of theory and practice of the user's technical training.

Certifications

Exhibition