edible oil refinery equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | according to the customer requirements |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | Doing |

| Type: | edible oil refinery equipment |

| Condition: | New |

| Customized: | Customized |

| Certification: | CE&ISO9001 |

| Origin: | Henan China (Mainland) |

| Usage: | Mainly used to refine edible oil |

| Production Capacity: | according to the customer requirements |

| Packing: | wooden case or according to the customer requirements |

| Delivery Date: | 50 days |

Product Description

Application of edible oil refinery equipment:

Coconut oil, soybean oil, mustard seed oil, cottonseed oil, sunflower seed oil, peanut oil, rice bran oil, safflower seed oil, corn germ oil. Camellia seed oil ,palm oil,olive oil, tea seeds oil,peanut oil ,sesame oil,etc.

Edible oil refinery equipment

Characteristics Edible oil refinery equipment

1.This units belongs to intermittent refining oil equipment, has all functions of large, small scale intermittent refining equipment, and better than them.

2.This equipment can produce high-cooking oil or salad oil.

3.This units complete set combined, selfprepare heat source, gas source, electrics control. Light weight, save electricity , convenient use.

4.This machine do not need special basis, either indoor or outdoor is OK, just need to make up power source, water, prepare coal, alkali, Pacid, active clay, edible salt and other material

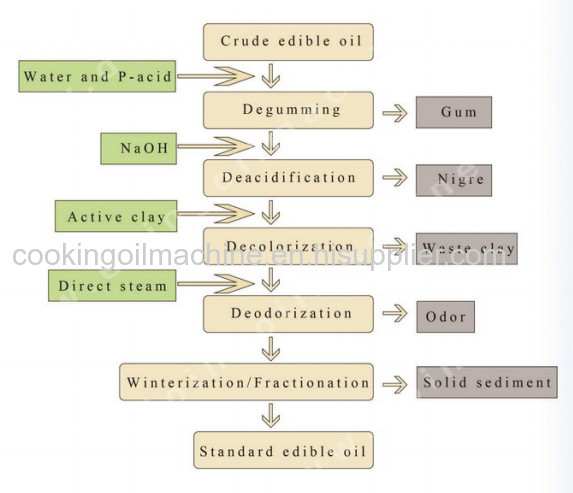

Units devices of edible oil refinery equipment

(1). Refining pot: uses washing method to separate soap residual from mixing oil, providing preparation for next step palm oil refining machine.(2).Decolor pot: used to remove off pigments, bleaching oils and grease dehydrate.

(3).Deodor pot: used to remove off oils odor, foreign smells (stainless made)

(4) Heattransfer oil stove: supply each device production needing heat energy, temperature reach above 280 ° C.

(5).Steam generator: produce the needing steam for de-odoring and distillation.

(6).Vacuum pump: supply needing vacuum for dehydrate, de-color, de-odor

(7).Press filter: filter clay, filter out clear oil.

(8).Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.

Edible oil refinery process