10-100T/D complete oil refinery equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500sets |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Oil Press, Oil Mill Manufacturer, Cold Oil Press, Hydraulic Oil Press, Small Oil Press |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Brand Name: | yuanyang |

| Steam consumption: | 450KG/T oil |

| Material: | stainless steel and alloy steel |

| Waste bleaching earth oil content: | <35% |

| Bleaching earth consumption: | 5~50Kg/T oil |

| Electric consumption: | 28Kwh/T oil |

| type: | semi-continuous |

| Production Capacity: | 500sets |

| Packing: | standard export package |

| Delivery Date: | within 5months |

Product Description

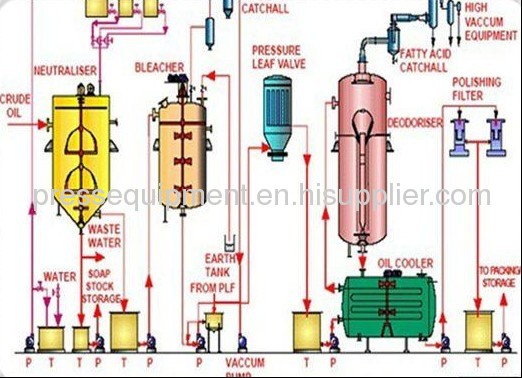

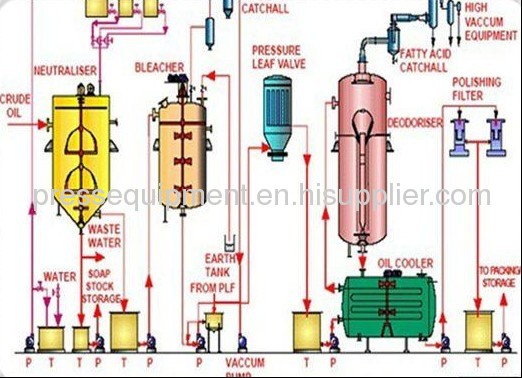

10-100T/D complete oil refinery equipment

The advantage of 10-100T/D complete oil refinery equipment

1. High refining reat with less loss

2. The product oil has consistent quality

3. No waste water during the process

2. The product oil has consistent quality

3. No waste water during the process

10-100T/D complete oil refinery equipment workshop content

oil refining workshop is processing different oil throught off impurity, degumming, decolor, deodorization, dewaxing, fractionation and other processes in order to achieve different edible oils standards and capabilities.

Currently, the China oil standards are divided into one, two, three, four; different oils quality standards for the different requirements.

oil refining workshop is processing different oil throught off impurity, degumming, decolor, deodorization, dewaxing, fractionation and other processes in order to achieve different edible oils standards and capabilities.

Currently, the China oil standards are divided into one, two, three, four; different oils quality standards for the different requirements.

The main charater of 10-100T/D complete oil refinery equipment

safety:

1. we using auto welding machine to make the reactor,which can quarrantee the quality of welding seam,avoid cracking and has a long life for about 8 years.

2. professional heating treatment and x-ray detection chamber for welding seam .

3. vacuum system to prevent oil gas be back to reactor causing accident.

4. with professional thermometer , professiona pressure gauge and safety valve.

environment friendly:

1.dedusting system to prevent gas and dust from coal burning

2.the exhaust gas will be recycled for heating reactor ,no gas pollution

3.well sealing on every junction parts to prevent gas leak,no smelly

longer life :

use Q345R special steel plate ,welding seam with auto welding an will get heating treatment and x-ray detection to extend the life of reactor to the most extend.

the life will 8 years

energy saving:

1. well sealing for heating system ,no gas leak and saving fuel.

2. the exhaust gas will be recycled for reactor heating

Reference photos of 10-100T/D complete oil refinery equipment

Reference photos of 10-100T/D complete oil refinery equipment