PE High Quality Jaw Crusher

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 20-60 sets per months |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Ore |

| Type: | Crusher |

| Brand Name: | MKD |

| Certificate: | ISO9001-2000; CE |

| Technology: | Welding |

| Wall thickness: | 8-10mm |

| Material of Jaw Plate: | Mn13 (High Manganese Steel) |

| Eccentric Shaft: | 45# Forged Steel |

| Production Capacity: | 20-60 sets per months |

| Packing: | In Nude or Wooden Package |

| Delivery Date: | 15-20 working days |

Product Description

Introduction of Jaw Crusher:

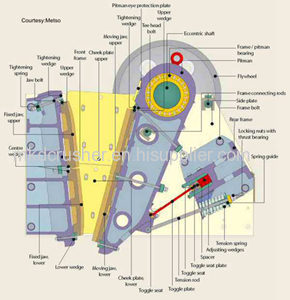

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

Jaw crushers are heavy duty machines and hence need to be robustly constructed. The outer frame is generally made of cast iron or steel. The jaws themselves are usually constructed from cast steel. They are fitted with replaceable liners which are made of manganese steel, or Ni-hard (a Ni-Cr alloyed cast iron). Jaw crushers are usually constructed in sections to ease the process transportation if they are to be taken underground for carrying out the operations.

Jaw crushers are classified on the basis of the position of the pivoting of the swing jaw

Blake crusher-the swing jaw is fixed at the upper position

Dodge crusher-the swing jaw is fixed at the lower position

Universal crusher-the swing jaw is fixed at an intermediate position

Type Hardness Abrasion limitMoisture contentReduction ratioMain use

| Jaw crushers | Soft to very hard | No limit | Dry to slightly wet, not sticky | 3/1 to 5/1 | Heavy mining, Quarried materials, sand & gravel, recycling |

| Gyratory crushers | Soft to very hard | Abrasive | Dry to slightly wet, not sticky | 4/1 to 7/1 | Heavy mining, Quarried materials |

| Cone crushers | Medium hard to very hard | Abrasive | Dry or wet, not sticky | 3/1 to 5/1 | Quarried materials, Sand & gravel |

| Compound crusher | Medium hard to very hard | Abrasive | Dry or wet, not sticky | 3/1 to 5/1 | Mine, Building Materials |

| Horizontal shaft impactors | Soft to medium hard | Slightly abrasive | Dry or wet, not sticky | 10/1 to 25/1 | Quarried materials, sand & gravel, recycling |

| Vertical shaft impactors (shoe and anvil) | Medium hard to very hard | Slightly abrasive | Dry or wet, not sticky | 6/1 to 8/1 | Sand & gravel, recycling |

| Vertical shaft impactors (autogenous) | Soft to very hard | No limit | Dry or wet, not sticky | 2/1 to 5/1 | Quarried materials, sand & gravel |

| Mineral sizers | Hard to soft | Abrasive | Dry or wet and sticky | 2/1 to 5/1 | Heavy mining |

| Crusher buckets | Soft to very hard | No limit | Dry or wet and sticky | 3/1 to 5/1 | Heavy mining, Quarried materials, sand & gravel, recycling |

Techincal Data of Jaw Crusher:

Model | Size of feed opening | Max. feed size | Capacity | Eccentric shaft rotate speed | Motor power | Closed side setting | Weight |

(mm×mm) | (mm) | (t/h) | (r/min) | (kw) | (mm) | (t) | |

PE-250×400 | 250×400 | 210 | 5-20 | 300 | 15 | 20-60 | 2.8 |

PE-400×600 | 400×600 | 340 | 16-65 | 275 | 30 | 40-100 | 6.5 |

PE-500×750 | 500×750 | 425 | 45-100 | 275 | 55 | 50-100 | 10.1 |

PE-600×900 | 600×900 | 500 | 50-120 | 250 | 55 | 65-160 | 15.5 |

PE-750×1060 | 750×1060 | 630 | 52-208 | 250 | 110 | 80-140 | 28 |

PE-800×1060 | 800×1060 | 650 | 85-228 | 250 | 110 | 100-200 | 30 |

PE-870×1060 | 870×1060 | 670 | 181-280 | 250 | 110 | 200-260 | 30.5 |

PE-900×1200 | 900×1200 | 750 | 140-320 | 200 | 132 | 95-165 | 50 |

PE-1000×1200 | 1000×1200 | 850 | 160-350 | 200 | 132 | 100-170 | 51 |

PE-1200×1500 | 1200×1500 | 1020 | 300-800 | 180 | 220 | 150-350 | 83 |

PE-1500×1800 | 1500×1800 | 1200 | 430-1000 | 160 | 355 | 220-350 | 122 |

PEX-250×750 | 250×750 | 210 | 13-35 | 330 | 22 | 25-60 | 4.9 |

PEX-250×1000 | 250×1000 | 210 | 16-52 | 330 | 30 | 25-60 | 6.5 |

PEX-250×1200 | 250×1200 | 210 | 20-60 | 330 | 37 | 25-60 | 7.7 |

PEX-300×1300 | 300×1300 | 250 | 16-104 | 330 | 55 | 20-90 | 11 |