Impact Crushing Machine With Rotor Assembly

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 20-60 sets per months |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | PF1010,PF1214,PF1210,PF1315,PF1415,PF1515 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Ore |

| Type: | Crusher |

| Brand Name: | Mekind |

| Certificate: | ISO9001-2000; CE |

| Material of Main Body: | Q235 |

| Material of Hammer Plate: | Mn13Cr2 |

| Technology: | Welding |

| Upshell-opening Method: | Manual |

| Type of chamber: | Two or Three Chambers |

| Production Capacity: | 20-60 sets per months |

| Packing: | Nude and Wooden Box |

| Delivery Date: | 15-20 working days |

Product Description

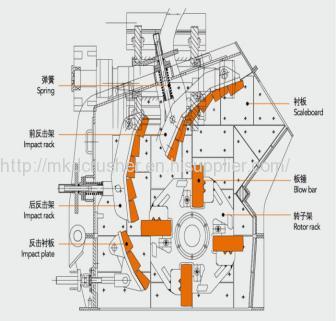

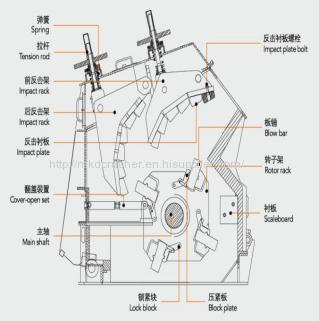

Operating Principle:

When the machine is working, the electric motor drives the rotator axle through V-belt. In that way, the material is crushed because of the high-speed impact of the board hammer on the rotator, and then it will be recrushed by the impact back plane, and then back to the board hammer. This process will be repeated for several times until the required particle size is got and the materials are delivered to the second crushing. At that time, the particles are small enough to get through the backlash between the hammer and the impact plane, which are the final products.

Preparation before starting:

1.Examine whether there is appropriate grease in the bearing.

2.Examine whether the joints are locked and add appropriate grease.

3.Examine whether all the fasteners are firm or not.

4.Examine whether there are hard trashes in the machine.

5.Examine whether the backlash between the impact back plane and the rotator hammer is appropriate.

6.Twisting the rotator and examine whether it is in good condition. There should be no damages on the board hammer or other parts.

Features:

◇ Heavy-duty, high inertia and semi-enclosed balanced rotor

◇ Newly designed wedge type rotor will make blow bar removal safer and easier

◇ Specially designed impeller bar design to allow extended life

◇ Rotor locking system for safer and quicker rotor maintenance

◇ Extra heavy duty solid rotor construction

◇ Large self-aligning spherical roller bearings with labyrinth seals

◇ Hydraulic adjustment mechanisms for primary and secondary curtains

◇ Quick and accessible breaker bars for easy replacement and repositioning

◇ Inspection doors in key areas

◇ Large, clear discharge opening

◇ Blow bars available in manganese and various compositions of chrome steels

Technical Data Of Impact Crushers:

Model | Sizes (mm) | Feed opening (mmxmm) | Max feeding size(mm) | Capacity (t/h) | Motor power (kw) | Weight(t) (Without Motor) | Dimension(mm) (LxWxH) |

PF-1010 | 1000x1050 | 400x1080 | 350 | 50~80 | 75 | 12.2 | 2858x2508x2470 |

PF-1210 | 1260x1050 | 400x1080 | 350 | 80~120 | 110 | 15.5 | 2690x2340x2890 |

PF-1214 | 1250x1400 | 400x1430 | 350 | 110~180 | 132 | 19 | 2690x2740x2890 |

PF-1310 | 1300x1050 | 490x1170 | 400 | 80~140 | 200 | 18.5 | 3330x2595x2862 |

PF-1315 | 1320x1500 | 860x1520 | 500 | 150~220 | 220 | 23 | 3432x3040x2862 |

PF-1316 | 1300x1600 | 800x1630 | 500 | 170~240 | 220 | 23.5 | 3432x3140x2862 |

PF-1515 | 1450x1500 | 900x1650 | 500 | 280~340 | 280 | 33 | 3950x3350x3055 |