High Effiecency Rotor Winding Machine Rotor Manufacturing Assembly Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ND-ZZX-4 |

|---|---|

| Means of Transport: | Ocean, Air |

| Conveyor: | Alloy aluminium frame |

| Automation: | Fully automatic |

| Application: | Motor/armature production |

| After sales servie: | Overseas Service Center Available |

| Machine color: | Ral9010 or as Per Customer Requirement |

| Certificate: | CCC |

| Size: | Middle size |

| Production Capacity: | 10 |

| Packing: | Wooden case which is suitable for sea transport |

| Delivery Date: | 120 days |

Product Description

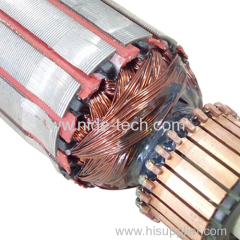

This automation rotor manufacturing assembly line is consisted of below machines, insulation paper inserting machine, armature rotor winding machine, commutator welding machine, wedge inserting machine, and rotor testing machine. The rotor will be carried by mechanical arm and converyor to the next machine.

Insluation paper inserting machine

This machine is used to inserting paper into rotor slot. The insulation material can be as per customer's requirement, DMD, DM, polyester film are all can be used in this machine.

armature winding machine

After doing paper inserting machine, mechanical arm and converyor will carry the rotor the rotor winding machine position. The machine is equipped with touch screen and PLC, winding parameter could be set and modified on the screen.

Commutator welding machine

It can weld both riser and hook type commutators. This machine is applied to DC motor and universal motor. It is controlled by PCL, all the data setting can be done on the touch sreeen. There are four power control method, namely secondary constant current, secondary constant voltage secondary constant frequency.

Wedge inserting machine

The wedge material can be as per customer's requirement, DMD, DM, polyester film are all can be used in this machine.

Rotor testing machine

It is suitable for testing less than 72 segments armature. The Voltage withstand test time could be set as per different requirements. Testing items could be screened.Testing data saved automatically, and could be traced and printed at any time

Applications:

It is suitable for power tooling motor armature production, especially with a great production valume.

Information needed for rotor production line inquiry

It will be better if customer could send us detailed drawing including below information.

1. Rotor lamination drawing

2. Rotor assemble drawing

3. Rotor stack drawing

4. Rotor winding diagram drawing: with rotor wire diameter and turn number

5. Commutator drawing

6. Shaft drawing

7. Required residual unbalancing volume and initial unbalancing volume

8. Wedge and insulation paper material

9. Required productivity

10. Other technical requirement

If possible, it will be better if customer can send us samples.

High Effiecency Rotor Winding Machine Rotor Manufacturing Assembly Line