air pocket and double winding machine

| Min. Order: | 8 spindle |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6000000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Shaoxing, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

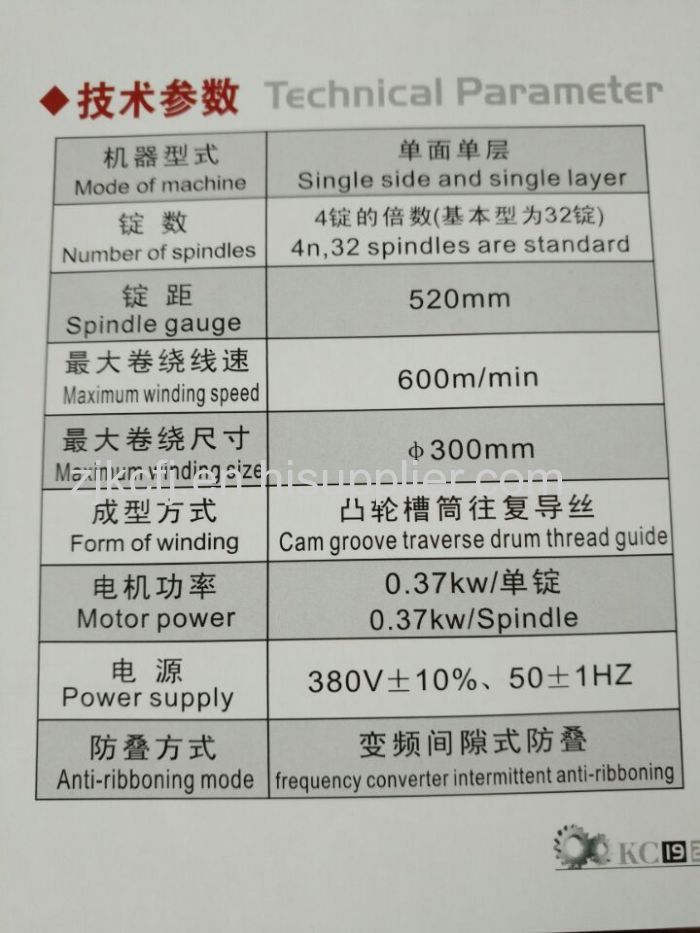

| Model No.: | CY205 |

|---|---|

| Means of Transport: | Ocean |

| Form of operation: | Single sides single layer |

| Spindle of number: | 8 spindles are basic model |

| Spinde guage: | 520mm |

| Maxmum winding speed: | 600m/min |

| Maxmum winding size: | Φ230*254mm |

| Form of molding: | Cam groove traverse drum thread guide |

| Motor power: | 0.37KW/spindle |

| Anti-ribbonning modle: | Frequency converter intermittent anti-ribbonning |

| Power supply: | 380V±10%,50±1HZ |

| Production Capacity: | 6000000 |

| Packing: | nake package |

| Delivery Date: | 60 days after receiving the downpayment |

Product Description

Applied range

It is applied for winding and blend doubling of different kinds of yarn, such as contton, woolen , chinlon, polyester ,reyon , spandex and etc. According to requirement configuration , 2or 3 plied yarns can be doubled with spandex on the cylinder tube..

Yarn doubling process

Put the base yarn on the yarn seat below the machine, yarn thread through ring of machine body, via panel yarn guide parts into tension device ,then repass yarn detector ---yarn cutter—hole of porcelain parts—head of yarn guide ,at last winding cross on the bobbin. If do with spandex, put spandex in the dedication fixed axis , pass from roller and yarn detector , blend with other yarns on the yarn cutter.

Doubling unit structure

3.4 Doubling unit structure

3.4-1 Yarn tension device

3.4-2 Automatic measuring equipment brake yarn

3.4-3 Spandex transporter (machine assembling device)

3.4-4 Over -feed device

3.4-5 Air pocket nozzle

3.4-6 Bobbin creel

3.5 Cam box

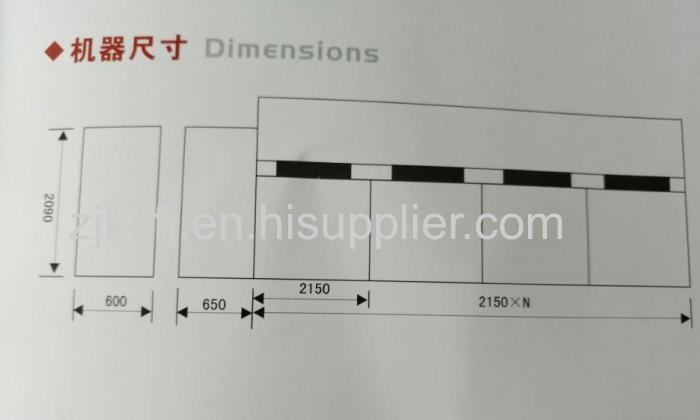

The dimentsions