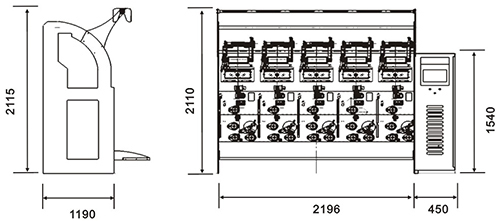

Yarn Air Pocket Winder

| Min. Order: | 6 SPINDLE |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Shaoxing, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | CY215 |

|---|---|

| Means of Transport: | Ocean |

| Form of operation: | Single sides single layer |

| Spindle of number: | Each section have 6 spindles |

| Spindle gauge: | 400mm |

| Maximum winding speed: | 1200m/min |

| Maximum winding size: | 192mm-260 mm |

| Form of molding: | Electronic yarn guide |

| Motor power: | 600W/spindle |

| Power supply: | 380V+ 38%,50+-1HZ |

| Anti-ribboning mode: | Electronic anti-ribboning |

| Production Capacity: | 500000 |

| Packing: | whole machine package |

| Delivery Date: | 60 days |

Product Description

Applied range

It's a cone-to-cone winding machine can be used of various yarns such as cotton,wool,nylon,chemical filament, rayon, spandex and so on. Also according to the requirement , it can be used to combining two ply or three ply into cheese packages.

Main Technical Parameters

CY215B High Speed Precision Air Pocket Winder | |

Form of operation | Single sides single layer |

Spindle of number | Each section have 6 spindles |

Spindle gauge | 400mm |

Maximum winding speed | 1200m/min |

Maximum winding size | 192mm~260 mm |

Form of molding | Electronic yarn guide |

Motor power | 600W/spindle |

Power supply | 380V±38%,50±1HZ |

Anti-ribboning mode | Electronic anti-ribboning |

Yarn winding process

Put the raw yarn in the yarn seat under machine, the yarn through the yarn guide ring and yarn guide ceramic part of panel into tensioner, then through yarn detector and enter overfeed yarn device or constant tension device, at last via the yarn guide move back and forth to winding on the take up bobbin. According to different demands, some winder need through overfeed pulley, lubrication system, air jet when traverse.